Zhangjiagang Boxin Machinery Co., Ltd.

Zhangjiagang Boxin Machinery Co., Ltd is

China Plastic Film Recycling Washing Line Manufacturers and

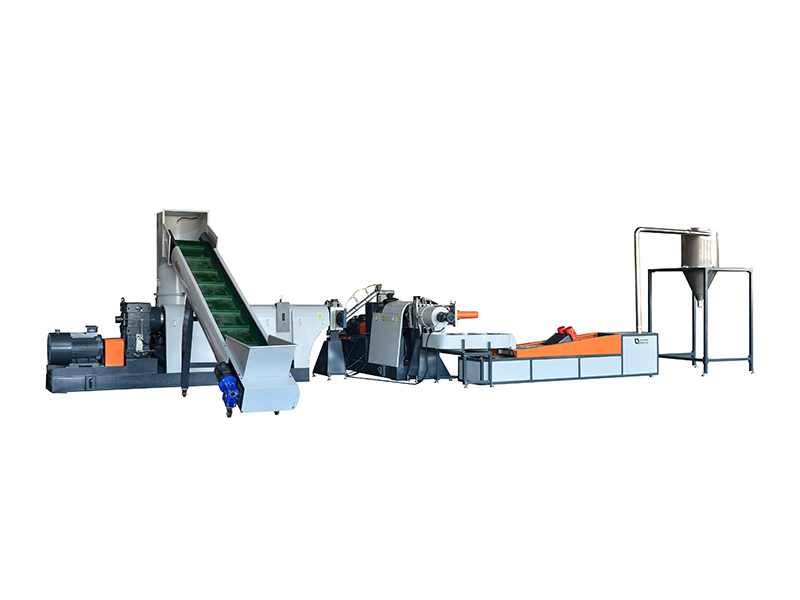

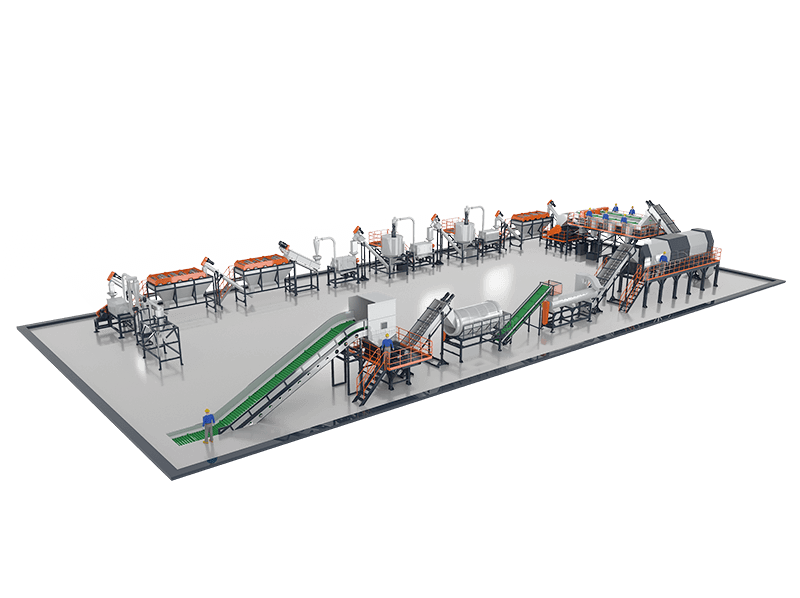

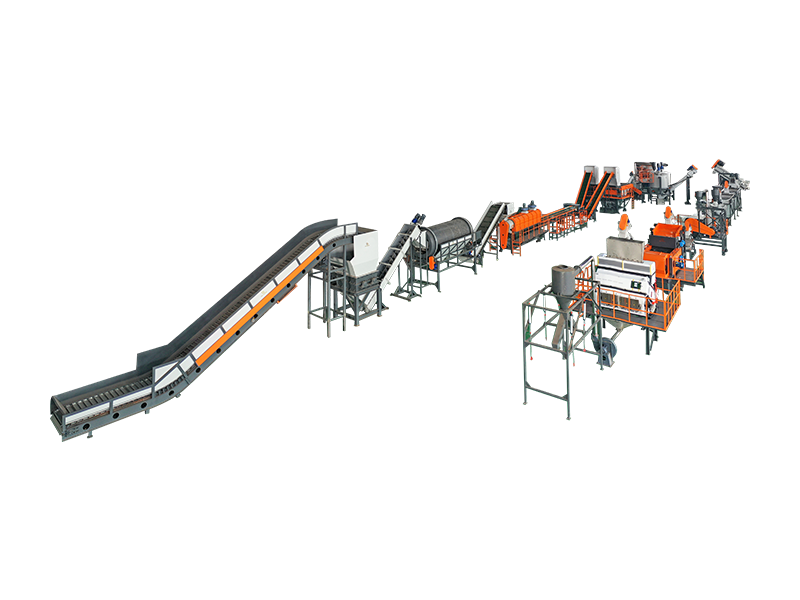

Custom Plastic Film Recycling Washing Line Factory, an innovative company that remains committed to plastic recycling and extrusion technology and specializes in providing plastic recycling washing and granulation equipment.

We are a professional supplier of customized solutions to plastic recycling, on the basis of our development teams and a wealthy content of industrial experience.

Main Products of Boxin: PET bottle recycling washing line, PE film /PP woven bag recycling washing line, HDPE /PP hard plastic recycling washing line, plastic pelletizing line and plastic shredder, plastic crusher machine.

EN

EN

English

English 简体中文

简体中文 Русский

Русский España

España عرب .

عرب .