Types of HDPE Washing Lines

There are various types and configurations of HDPE washing lines, each suited to specific raw materials and contamination levels. Choosing the right washing line for your material stream and end-product goals is essential. Below are common categories of HDPE washing lines and their typical applications:

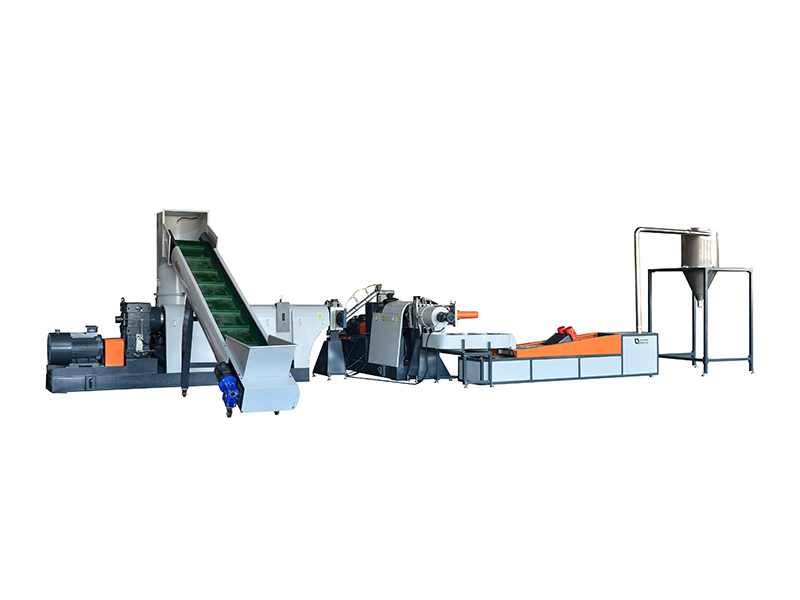

Basic HDPE Washing Line (Entry-Level):

Typically consists of a crusher, one or two washing tanks, a friction washer, and a dewatering/drying unit. This type of line is ideal for small companies or startups handling single-type waste.Basic lines cover the core cleaning stages at an affordable entry-level cost.

They are suitable for lower capacities (typically around 500–1000 kg/h) and moderate contamination. If you are just entering the recycling industry or have limited throughput needs, a basic HDPE washing line can reliably produce clean flakes for sale or further processing.

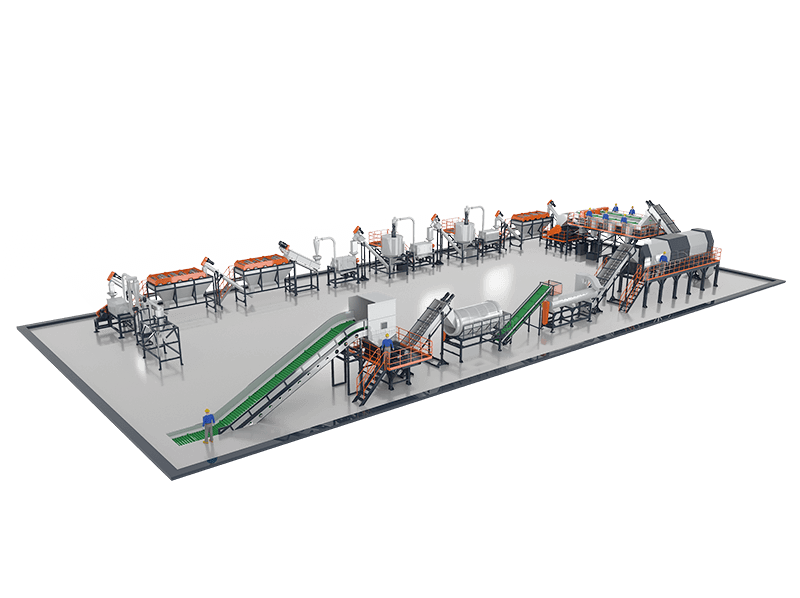

(High-Purity) HDPE Washing Line:

Includes additional steps and enhanced cleaning capabilities to handle dirtier or more challenging materials. For example, they may feature hot washing modules, optical sorters, and eddy current separators to remove specific contaminants.

These systems provide more thorough cleaning to remove oils, adhesive residues from labels, and even odors from the plastic. Although advanced lines have higher initial costs (including hot washers and extra drying stages), the benefit is higher-quality recycled flakes that can fetch better prices and meet stricter end-user requirements.

HDPE Washing Line (Tailored Solutions):

Designed primarily for HDPE containers that previously held chemicals and for post-consumer miscellaneous HDPE bottles (including pump dispensers, foil liners, etc.). This type of waste cannot be processed using a basic line configuration and requires a setup tailored to the specific contaminants present in the raw materials.

Standard Process of HDPE Washing Line

To transform dirty HDPE waste into clean, reusable plastic, an HDPE washing line must undergo a series of processing stages. Each stage involves specialized equipment working in coordination to form a continuous production line. Understanding this process flow is crucial for buyers, as it helps you focus on the key equipment and features when evaluating products from different suppliers. Below is a breakdown of the key components and steps in a typical HDPE washing line process flow:

|

|

|

|

|

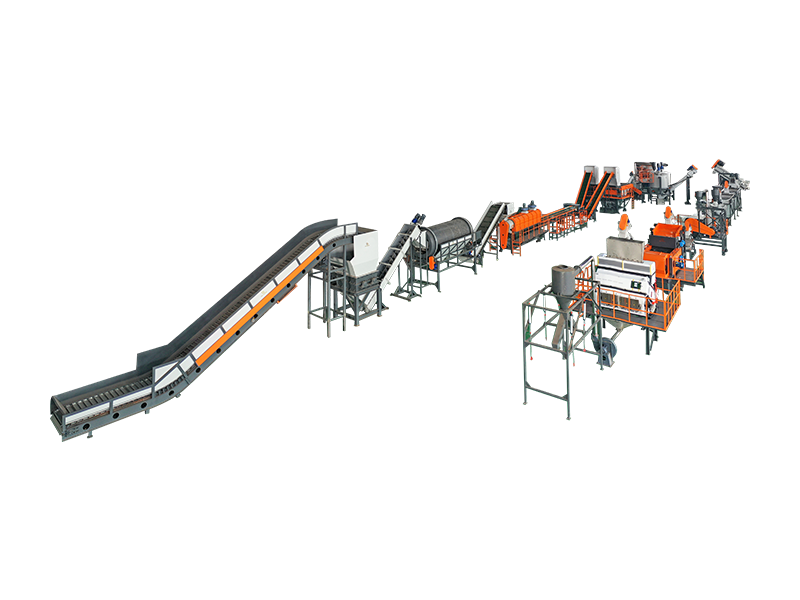

1. Feeding & Size Reduction System

The process begins by feeding the HDPE raw material into the production line. Large bales of bottles or bulky plastic are loaded into a granulating or shredding system via a belt conveyor. The goal is to cut the plastic into sufficiently uniform small flakes to enable effective washing. By using a powerful shredder capable of handling bulky material directly, the need for pre-shredding is eliminated.

Key features to watch for at this stage include wear-resistant rotors and blades (since HDPE is very hard and dulls tools quickly), and ideally, the conveyor should be equipped with a metal detector to catch any mixed-in metal waste. Removing metals at this point helps protect downstream granulators and shredders from damage. After the size reduction stage, you’ll typically end up with HDPE flakes about 10–30 mm in size, suitable for washing.

Key Features:

Belt conveyor feeding system supports full-sized bales or large bundles without pre-treatment

High-strength rotor shaft eliminates the need for pre-shredding

Produces uniform flake size, suitable for direct cleaning

Low maintenance frequency, engineered for continuous, stable operation

|

2. Hot Washing System

The flake material enters the washing tank or washer, where it is agitated in hot water—typically with caustic soda—to remove grease, oil, and adhesive residues. This step is especially important for items like oil containers or bottles with self-adhesive labels.

Key Features:

Supports both alkaline and chemical washing solutions

Stable temperature control for optimized cleaning results

Especially suitable for input materials with chemical residues or oily contaminants

|

3. High-Speed Friction Washer

After the soaking stage, the plastic flakes pass through a friction washer. This is a cylindrical high-speed cleaning unit with a rotating rotor that uses water and centrifugal force to scrub the plastic flakes. It effectively removes residual dirt, paper fibers (from labels), and small particles stuck to the plastic surface. The friction washer's casing is typically made of stainless steel and features a screen that discharges dirt and moisture while retaining the plastic flakes.

Key Features:

Dual-stage friction design for enhanced cleaning intensity

Constructed with wear-resistant materials for long-term durability

Supports continuous high-speed operation without clogging or downtime

|

4. Sink-Float Separation Unit

High-density polyethylene (HDPE) is a lightweight plastic (with a density of about 0.95 g/cm³), which means it floats on water, while many contaminants are heavier and sink. Washing lines take advantage of this property by using a float-sink separation tank—typically a large water basin that allows flakes to separate based on density over time.

Key Features:

Effectively removes non-HDPE impurities, improving final product quality and reducing waste.

|

|

|

|

|

|

5. Dewatering & Drying System

After cleaning, HDPE flakes must be dried. Excess moisture can cause problems in subsequent processes such as extrusion or pelletizing, and if the flakes are stored, it can lead to mold or unpleasant odors. Drying is typically done in two stages: first, a mechanical dryer spins the flakes at high speed to sling off water. These units usually reduce moisture content to around 5%. Then, the partially dried flakes pass through a hot air pipe system, where heated air evaporates the remaining moisture.

A well-designed HDPE washing line can achieve a final moisture content below 2%. Low moisture is crucial to prevent clumping and to ensure the flakes are immediately ready for use.

Key Features:

High-speed centrifugal dewatering combined with hot air pipe drying

Delivers stable operation, even under high throughput

Prevents moisture-related quality issues in subsequent extrusion or granulation stages

|

6. Bagging & Packaging Unit

The final step is collecting the clean, dry HDPE flakes. Many production lines feature a bagging station or silo at the end. The bagging system typically includes a storage hopper and a weighing system for filling jumbo bags.

|

|

|

|

Industry Knowledge Extension :::

More information about HDPE recycling Production Line

|

|

|

Choosing a Chinese HDPE Washing Line Supplier: Company Quality, Factory, and Service

Manufacturer vs. Trading Company:

First, determine whether you’re dealing with an actual manufacturer (factory) or a middleman/trading company. Manufacturers produce the equipment themselves and typically offer better control over quality and customization.

Trading companies might offer lower prices or a broader product range, but they often lack the same level of technical expertise or support.

Ideally, buying directly from a manufacturer ensures you can visit their factory, see the production process firsthand, and communicate directly with engineers. This also proves valuable when you need spare parts or custom components, as manufacturers can respond more easily to such needs.

Company Reputation and Experience:

Research the company’s background. How many years have they been in the plastic recycling machinery industry? Do they specialize in washing lines, or do they offer a wide variety of products? Companies that focus on plastic recycling (washing and pelletizing) and have long-term experience are preferable—they’re more likely to understand common challenges and how to design effective solutions.

Customization and Flexibility:

If you have special requirements, assess the supplier’s willingness and ability to meet them. A good manufacturer will listen to your needs and may proactively adjust designs or add extra features.

If a supplier only pushes standard models and avoids discussing your specific materials or needs, that’s a red flag—they may be more interested in a quick sale than in delivering the right solution.

On the other hand, if the supplier asks detailed questions about your material type, contamination level, and expected output, it’s likely they’re trying to ensure their solution truly fits your situation. This consultative approach is a sign of a responsible and serious company.

FAQ & Expert Tips: Most Common Buyer Questions

Straight Answers to the Questions You Might Be Hesitant to Ask

1. What Is an HDPE Washing Line and Why Is It Important?

An HDPE washing line is an integrated mechanical system designed to recycle high-density polyethylene (HDPE) plastic through thorough cleaning. It includes the following steps: shredding the plastic into flakes, washing to remove contaminants, density-based separation of impurities, and drying the cleaned plastic.An HDPE washing line is an integrated mechanical system designed to recycle high-density polyethylene (HDPE) plastic through thorough cleaning. It includes the following steps: shredding the plastic into flakes, washing to remove contaminants, density-based separation of impurities, and drying the cleaned plastic.

2. What raw materials can an HDPE washing line process?

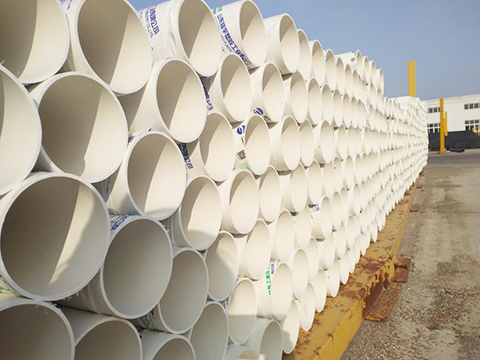

An HDPE washing line can process various types of rigid HDPE waste. Common raw materials include HDPE bottles and containers (such as milk jugs, shampoo bottles, detergent bottles), industrial HDPE drums and oil containers, HDPE pipes and profiles, and injection-molded HDPE products (crates, buckets, chairs, toys, etc.).

3. How much does an HDPE washing line cost?

Prices vary widely. As mentioned earlier, a basic, small-capacity HDPE washing line starts at around $50,000, while large, fully equipped lines can cost several hundred thousand dollars. A typical mid-range system (e.g., fully functional with a capacity of around 1000 kg/h) usually ranges from $80,000 to $150,000, depending on the manufacturer and options. Pricing depends on factors such as the number of machines/stages in the line, component quality, level of automation, and any custom features. Additionally, remember to budget for freight, import duties, installation, and commissioning beyond the machine price.

4. What are the ongoing maintenance requirements for an HDPE washing line?

Maintenance tasks include daily cleaning (e.g., removing sludge from washing tanks, cleaning filters and screens), blade and tool upkeep (sharpening or replacing shredder/granulator blades at recommended intervals), bearing lubrication, and checking motors and gearboxes for unusual noise or overheating. Wear parts like friction washer paddles or dewatering screens may need replacement after a period of use.

5. Are HDPE washing lines made in China reliable and up to international standards?

Yes, many Chinese-made HDPE washing lines are highly reliable and designed to meet international standards, especially those from reputable manufacturers. Over the past decade, Chinese companies have significantly improved product quality and often use components comparable to Western equipment (e.g., Siemens motors, Schneider Electric parts, SKF bearings). They also ensure compliance with safety standards, such as obtaining CE certification for the European market when necessary. For instance, high-quality Chinese suppliers follow ISO manufacturing processes, use electrical components that meet European standards, and conduct thorough testing to ensure performance.

6. What after-sales support and services can I get from the supplier?

For such a complex system, after-sales support is crucial. From a good supplier, you can expect services such as technical support and spare parts supply. Boxin offers a warranty (typically 12 months), during which they will send replacement parts if any components fail due to quality issues. After the warranty period ends, they continue to support you—typically, you can purchase parts and receive technical assistance throughout the machine’s entire service life.

EN

EN

English

English 简体中文

简体中文 Русский

Русский España

España عرب .

عرب .