Boxin Signature Tech – Core Advantages

|

High-torque, low-RPM drive

-

Ø 350 – 1100 mm sealed rotor, heavy-duty inertia; 22 – 200 kW motors.

-

15 – 25 % lower energy use than conventional granulators.

|

3×-life wear liners

Optional hardened-steel or ceramic-composite liners boost chamber life ≥ 3× when processing sand- or glass-fiber-contaminated post-consumer scrap.

|

Flexible knife library

Claw, V-cut and double-scissor styles swap in minutes to balance grip and fine-flake ratio.

|

40 mm composite isolation base

Operating noise ≤ 85 dB, meeting plant environmental limits.

|

Dual-hydraulic platform

Hydraulic hopper door + hydraulic screen drawer enable maintenance or mesh change in 20 s—downtime slashed ≥ 40 %.

|

End-to-end safety

Auto-reverse overload, current monitoring, CE/UL control panel, door interlocks & E-stop, NFPA 652-compliant dust controls.

|

|

Working Principle of Waste Plastic Crusher Machine

Feeding:

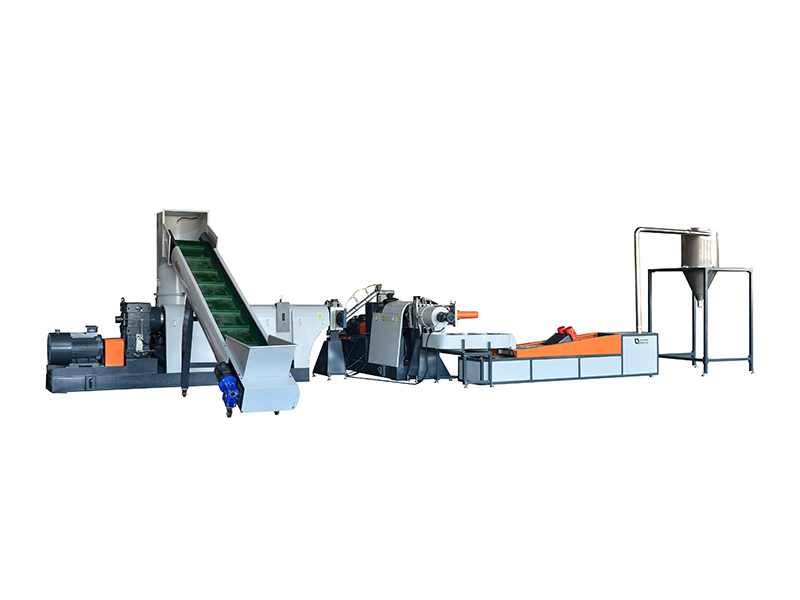

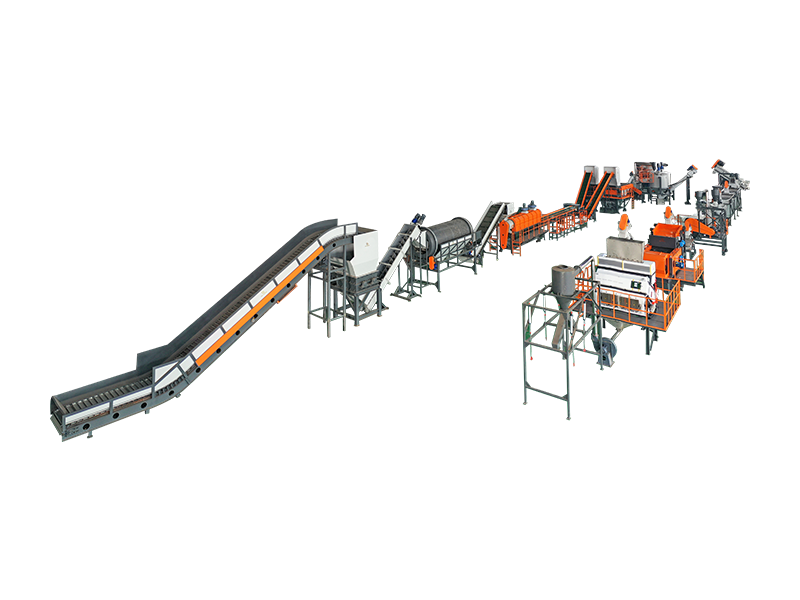

Plastic waste is delivered to the inlet of the crusher machine at a steady rate via a belt conveyor.

At this stage, any non-plastic contaminants (such as metals) should be filtered out to prevent blade damage during the crushing process.

Initial Cutting and Crushing:

Once inside the crushing chamber, the rotor spins at high speed, driving the moving blades into contact with the fixed counter blades mounted on the chamber wall. This interaction generates a combined cutting, tearing, and shearing effect that breaks down the plastic.

The staggered arrangement of the blades continuously draws the plastic in and cuts it, whereas dull or poorly designed blades would cause the plastic to simply bounce around.

Screen Classification:

After being cut into smaller pieces by the blades, the plastic fragments either fall through the screen or remain in the cutting chamber for further size reduction.

Typically, the machine is configured to crush plastic into pieces of approximately 10–50 mm within the chamber, which are then refined into final granules through screens with apertures of around 8–20 mm. This means each piece of plastic undergoes multiple cuts—circulating within the chamber—until it becomes small enough to pass through the screen. This mechanism ensures consistent output size.

Discharge of Crushed Material:

In basic models, the granules fall directly into a collection bin or onto a conveyor belt below.

Boxin adopts air-conveyed discharge: a blower creates suction that extracts plastic flakes from the crusher and transports them via piping to a cyclone collector or collection bag.

This pneumatic conveying system not only efficiently transports the recycled plastic but also helps to slightly cool the material (as crushing generates heat) and separate dust.

Safety and Control:

Built-in safety features protect both the operator and the machine during operation.

Key Considerations for Selecting a Plastic Crusher Machine

Material Compatibility and Capacity:

Start by assessing the types of plastics the crusher machine can handle and its processing throughput. Most industrial plastic crushers are versatile and can process various thermoplastics—including PE, PP, PVC, ABS, and PS—whether they are rigid components or soft films.

Also, consider the feed opening size and feeding method. For example, large-diameter pipes or oversized containers like drums may require a wider hopper or a pre-crushing stage.

Cutting Mechanism (Blades and Rotor):

At the heart of every plastic crusher machine is its cutting system. Key specs include rotor size and type, number of blades, and blade material. Choose a rotor design suitable for your plastic type—some machines use open rotors for better airflow when processing films, while others feature staggered “V-cut” blades for consistent cutting of thick solids.

Blades (also called cutters) are usually made of high-grade tool steel. D2 alloy steel is a common material offering high hardness and wear resistance. Quality blades can be resharpened multiple times, extending lifespan and reducing replacement costs. Blade configurations also matter:

-

Claw blades are ideal for gripping and cutting bulky solids.

-

Flat blades are suitable for clean slicing of thinner materials.

-

V-shaped blade arrangements pull material to the center for evenly distributed cutting.

Many crushers are equipped with multiple fixed (stator) blades in the chamber and multiple rotating blades on the rotor. For example, a typical medium-sized granulator might have 3 rows of rotating blades and 2 rows of stator blades. More blades typically mean finer and faster cutting—but also require higher power.

When comparing models, pay attention to the blade clearance and whether it's adjustable. Tight, adjustable blade gaps (e.g., 0.2–0.5 mm) allow for highly precise cuts and uniform particle size. A well-designed cutting chamber should also feature replaceable wear liners—hardened plates on the side walls absorb abrasion and greatly extend the machine’s structural life.

Screens and Output Size Control:

Plastic crusher machines use screens or sieves to determine the final size of crushed plastic pieces. Positioned beneath the rotor, these screens have holes of various diameters (commonly from 5 mm to 50 mm). Only particles small enough can pass through, ensuring a consistent recycled material size. Oversized fragments remain in the chamber for further cutting.

Boxin’s heavy-duty crushers offer hydraulic screen drop mechanisms for faster cleaning and screen replacement—a very useful feature since screens can clog or wear over time. This significantly reduces downtime during maintenance.

Safety Features and Automation:

Modern plastic crusher machines should at minimum include an emergency stop button and safety interlock systems. For example, if the hopper or screen chamber is opened during operation, the machine should automatically shut down.

Also look for overload protection and automatic rotor reversal: if large materials cause blockages or motor overloads, the system can detect the issue and reverse the rotor briefly to clear the jam, preventing damage. Many industrial machines also include current monitoring and torque-limiting controls to protect the motor from overload.

Another valuable feature is a built-in or optional metal detector on the feed conveyor. If nails, bolts, or other metallic contaminants are detected in the plastic stream, the system will pause or divert the feed to prevent blade breakage.

Maintenance and Durability: Ensuring Long Service Life

Daily Maintenance Tasks:

Establish a routine maintenance schedule. This includes regularly inspecting and cleaning the cutting chamber—plastic residue, dust, and debris can accumulate around the blades and screens. After heavy use (daily or per shift), it's best to clear out all remaining plastic fragments and check for clogged screens.

Blade Maintenance and Replacement:

Blades are critical wear components that dull over time. Plan to sharpen or replace the rotating and fixed blades at specified intervals, depending on usage and material type. Some operators keep a spare set of blades to maintain uptime—using one set while the other is being serviced.

Blades in crusher machines are typically resharpenable multiple times until they reach their minimum size. Operators can send dull blades to a grinding facility or use in-house sharpening equipment if available.

Keeping blades sharp is essential—dull blades lead to inefficient cutting, overheating, motor overload, and inconsistent particle sizes. Always follow safety protocols when handling blades: ensure the machine is fully powered off and locked out before entering the cutting chamber for blade changes.

Boxin’s machines simplify blade maintenance with hydraulic opening designs, allowing easy access to the rotor and screen. This lets technicians safely and quickly replace blades and screens. When reinstalling blades, it's crucial to adjust the clearance between the fixed and rotating knives (usually within tenths of a millimeter). Manufacturers provide gap specifications to ensure effective cutting without blade collisions.

Lubrication and Mechanical Checks:

Lubricating moving parts is another daily task. Bearings, gearboxes (if present), and pivot points (e.g., hopper hinges) should be greased or oiled according to the manufacturer’s guidelines.

Also, routinely check belt tension (if the rotor is belt-driven) and inspect for belt wear. Slipping or worn belts reduce performance and should be tightened or replaced as needed.

Maintaining Overall Machine Health:

As part of preventive maintenance, monitor the machine’s performance. Unusual noise, vibration, or decreased output can indicate problems—such as loose blades, worn bearings, or material blockage. It’s better to stop the machine and inspect early rather than risk severe damage by continuing to run it.

During routine checks, make sure all safety features—such as interlocks and emergency stops—are functioning properly. For example, if the interlock switch fails and the machine doesn’t shut down when the hopper is opened for cleaning, it poses a serious safety hazard.

Avoid Overloading the Crusher:

Avoid running the crusher machine beyond its rated capacity. Consistently pushing it beyond its design limits shortens its lifespan—leading to motor overheating and accelerated wear of mechanical parts. If you frequently exceed capacity, consider adding a pre-crusher or upgrading to a larger unit rather than overworking the current machine.

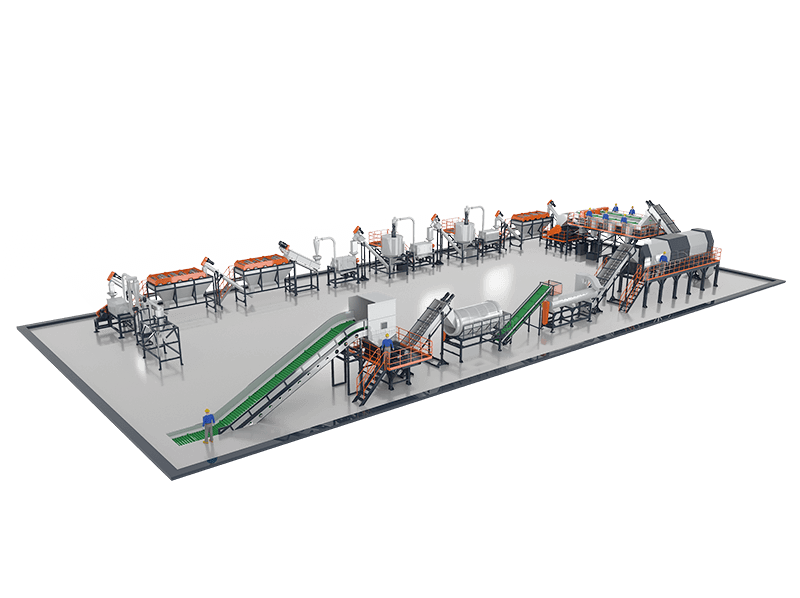

Equipment Photo Gallery

Heavy-Duty Main Shaft |

Dynamic Balancing Treatment |

Fixed Blades and Rotating Blades |

Screen Mesh |

Dual Hydraulic Arms |

Hydraulic Cylinder |

FAQ & Expert Tips

Straight Answers to the Questions You Might Be Hesitant to Ask

1. What types of plastic can a waste plastic crusher machine process?

Common materials include PET, PP, PE, PVC, and ABS. With proper configuration, the machine can handle both rigid plastics like bottles and pipes, as well as softer materials such as films and woven bags.

2. What is the output particle size? Can it be adjusted?

The output size depends on the screen inside the crusher. You can adjust the size of the plastic flakes by replacing the screen with different hole diameters.

3. What is the expected processing capacity of a plastic crusher machine?

Capacity varies by model and size. Keep in mind that actual output depends on the material type (film vs. solid blocks) and feeding consistency. It’s wise to choose a machine with a slightly higher capacity than your current needs to handle surges or tougher batches without overloading.

4. What safety features do these machines have?

Safety features include emergency stop buttons, safety interlock systems, overload protection, and automatic rotor reversal. Control systems typically include indicator lights or alarms to alert for issues like motor overload or overheating.

5. How often do the blades need sharpening or replacement?

This depends on usage and material type. When output drops or the machine struggles to cut, it's time to sharpen the blades.

6. Can the machine be customized to meet our specific needs (size, power, features)?

Yes, you can typically request more powerful motors, different blade types or configurations, and various screen sizes. The hopper can be enlarged or modified to match your feeding method. Optional features like soundproof enclosures, wet-crushing with water feed, or metal separators can be integrated. The electrical system will be built to match your local voltage/frequency specs. For special requirements—such as output size, structural materials, or production line integration—consult your supplier.

7. What kind of warranty and after-sales support is provided?

Key components of the machine usually come with at least a 1-year warranty, covering manufacturing defects and failures under normal use.

8. What is the lead time for manufacturing and delivery?

Lead time varies, but generally ranges from 30 to 60 days from order placement for production and assembly. Custom configurations or high factory workloads may extend this timeframe.

EN

EN

English

English 简体中文

简体中文 Русский

Русский España

España عرب .

عرب .