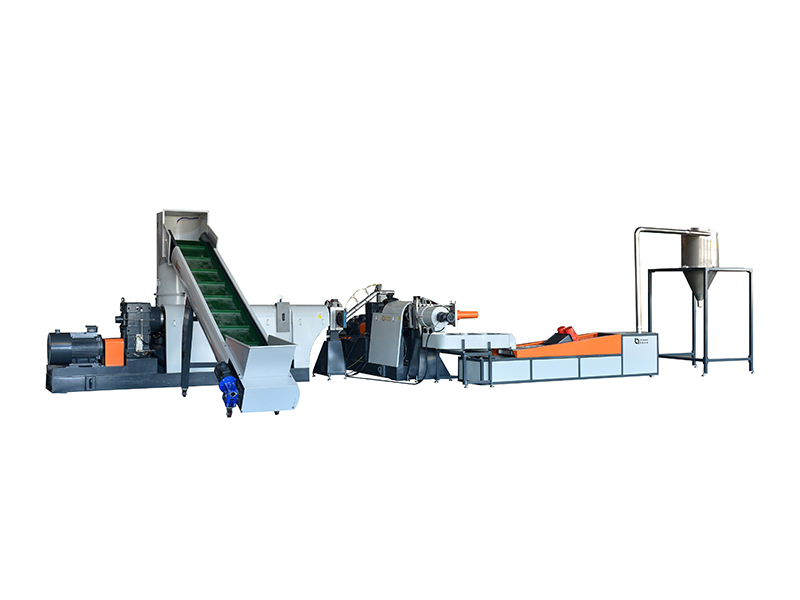

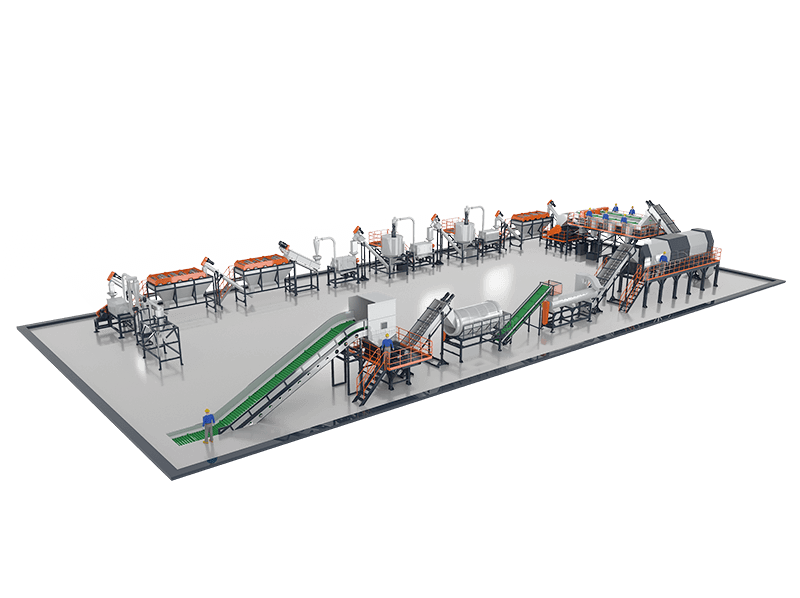

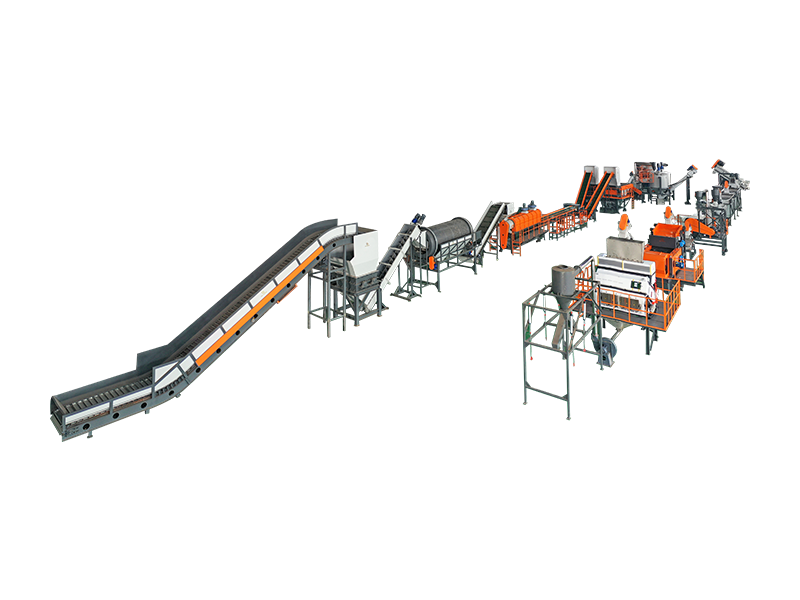

PE Film Pelletizing Machine

The PE film pelletizing machine we offer is designed for recycling common soft plastics such as HDPE, LDPE, LLDPE, PP, and PS.

It is ideal for processing both clean production scraps and post-washed materials.

Whether you're recycling clean film waste or handling contaminated materials like woven bags, agricultural film, or dirty post-consumer waste, we provide the right single-stage or two-stage pelletizing solutions to match your needs.

Our systems ensure that the final pellets meet high-quality standards, regardless of input complexity.

EN

EN

English

English 简体中文

简体中文 Русский

Русский España

España عرب .

عرب .