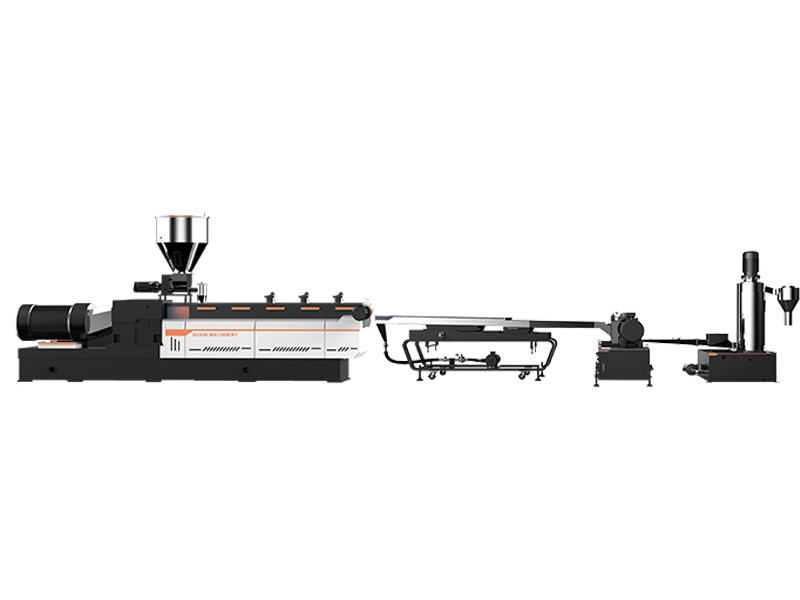

Pet Bottle Flakes Pelletizing Machine

The PET flake pelletizing machine melts, extrudes, and cuts the cleaned PET bottle flakes into uniform small cylindrical pellets, which can be reused as raw materials for new plastic products.

Web Menu

Product Search

Exit Menu

The PET flake pelletizing machine melts, extrudes, and cuts the cleaned PET bottle flakes into uniform small cylindrical pellets, which can be reused as raw materials for new plastic products.

Uniform Composition: During the pelletizing process, PET is thoroughly melted and homogenized, resulting in pellets with more consistent viscosity and material properties. Any additives (stabilizers, viscosity enhancers, colorants) can be evenly mixed.

Improved Purity: The pelletizing process includes melt filtration to remove the final traces of contaminants, resulting in a cleaner material.

Versatile Reusability: Recycled PET pellets can be used in a wide range of applications—from textile fibers to packaging materials—just like virgin plastic resin.

The screw design offers excellent shearing and mixing performance, ensuring a uniform PET melt and stable IV (Intrinsic Viscosity).

The resulting pellets are consistently sized, and the melt flow has no dead zones, which effectively reduces hollow pellets and yellowing issues.

Enhanced degassing performance through forced vacuum venting effectively removes moisture and volatile compounds.

This reduces the risk of thermal degradation, helping to preserve the molecular weight and intrinsic viscosity (IV) of PET.。

The system allows for flexible adjustment of screw combinations, thread configurations, temperature zones, and shear intensity.

This ensures compatibility with PET flakes of varying IV levels and different impurity contents.

Supports the direct addition of additive masterbatches, modifiers, and fillers to enhance material properties.

Enables efficient compounding of PET with other materials (e.g., glass fiber, flame retardants), making it ideal for specialized and functional applications.

|

|

|

||

PET Flake Feeding

|

Melting and Extrusion:

|

Degassing (Venting)

|

Melt Filtration System

|

Pelletizing (Cutting)

|

Cooling and Drying

|

Collection and Packaging

|

|

The single-screw extruder is mechanically simpler—with one screw inside the barrel. Historically, PET flakes needed to be crystallized and thoroughly dried before extrusion to avoid rapid IV loss, as the single screw has limited devolatilization capacity.

Advantages of single-screw machines include: generally lower cost, easier maintenance (fewer moving parts than twin-screw), and slightly lower power consumption per kilogram at smaller scales.

However, disadvantages compared to twin-screw include: weaker mixing and dispersing strength (which is crucial for thoroughly melting PET and additives), and generally lower vacuum degassing efficiency (twin screws offer more surface renewal for gas escape).

In addition, at high throughput, single-screw machines must be very large, which becomes expensive. In practice, single-screw PET pelletizing lines are typically chosen for small to medium capacity needs or where budget constraints make some performance trade-offs acceptable.

Twin-screw extruders are known for excellent mixing, compounding, and devolatilization capabilities. For PET recycling, twin-screw systems have become very popular because they can more effectively handle material issues (such as moisture and viscosity).

Advantages of twin-screw pelletizers include:

Excellent material mixing and homogenization – the two screws thoroughly mix the melt, ensuring consistent melt quality and color. This reduces problems like uneven heating.

Enhanced degassing – PET melt degasses very effectively in twin-screw extruders, meaning pre-drying is often unnecessary.

Higher output from smaller machines – twin-screw extruders usually have higher throughput than single-screw machines of the same screw diameter when processing PET, due to strong mixing and heat transfer.

The disadvantages mainly relate to cost and complexity: twin-screw extruders are more expensive to manufacture (two screws, more complex gearbox), and maintenance is more complex (screw elements wear).

Nevertheless, for many medium- and large-scale PET recycling operations, twin-screw pelletizers remain the preferred solution because they produce the most consistent, high-quality pellets. These machines preserve PET’s intrinsic viscosity and ensure stable output, which is critical for downstream use in high-quality products.

As previously mentioned, PET pelletizing lines can be equipped with different pellet cutting systems:

Strand Pelletizing:

A low-cost, simpler method. Best suited for lower throughputs (e.g., a few hundred kg/hour or less) and when skilled operators are available. It is less suitable for very large production lines, as managing many strands at high output is challenging.

Water Ring Pelletizing:

Moderate in complexity. Die-face cutters and the water ring can handle medium output and help control most of the mess. (Commonly used for soft plastic film pelletizing.)

Underwater Pelletizing:

A high-end method. Suitable for large-scale production (500 kg/hour to several tons/hour), and produces the most uniform pellets. It also has the advantage of immediately isolating the melt from air, which helps prevent any oxidation of PET at the die. The downside is that underwater cutting equipment and control systems are more expensive.

Boxin Machinery’s PET pelletizing lines come standard with strand pelletizing, with the option to upgrade to underwater pelletizing for those seeking higher automation and pellet consistency.

While single-screw and twin-screw systems cover the main distinctions, a few other variations are worth noting:

Twin-Screw Compounding Lines (Reactive Extrusion):

Some twin-screw pelletizers are designed not just for basic recycling, but also for adding modifiers or performing reactive extrusion (e.g., adding chain extenders during extrusion to boost PET IV). These lines feature side feeders for adding additives or fillers. They blur into compounding extruders but are relevant if the buyer intends to produce enhanced PET compounds (with glass fiber) or increase molecular weight through reactive chemistry during pelletizing.

Integrated Continuous SSP Systems:

A highly specialized, high-end type where pelletizing is combined with immediate Solid-State Polycondensation (a process that raises PET IV in solid pellet form). This is not common in standard machines but is an option for large-scale bottle-to-bottle recycling operations.

Quality Requirements:

If maximizing IV and pellet quality is critical, a twin-screw extruder with excellent degassing and underwater pelletizing is recommended.

Budget:

Single-screw lines are more cost-effective. They can handle many applications—especially if the manufacturer has optimized the PET design. For medium budgets, a single-screw system with good vacuum capability can provide a reliable solution.

Material Form:

If handling inconsistent PET waste (e.g., thick lumps, preform runners, or molded PET chunks), twin-screw systems can process melting more evenly.

Maintenance & Skill Level:

Twin-screw machines require maintenance of both screws and tight tolerances; users with lower technical skills may prefer the simplicity of single-screw systems. On the other hand, many companies are already familiar with twin-screw maintenance, as it’s common in plastics recycling.

As a professional Pet Bottle Flakes Pelletizing Machine manufacturer in China, Boxin Machinery stands out in the industry with its OEM and custom engineering capabilities. For global B2B buyers, the ability of the system to adapt to local raw material conditions, regulatory requirements, and factory layout is a key factor in procurement decisions.

|

Tailored Engineering |

Pre-Sales Testing & Consultation |

Global Installation & Training Services |

After-Sales Technical Support |

|

|

|

|

|

|

1. Machine Price Range:

The price of a PET flake pelletizing machine varies widely depending on capacity, brand, and configuration:

Small or Entry-Level Systems (~200–300 kg/h single-screw lines) may range from USD 30,000 to 70,000. On some Chinese product listings, basic small-scale plastic pelletizers are priced around USD 60,000.

Medium-Capacity Machines (e.g., 500–600 kg/h, typically twin-screw) are generally priced around USD 60,000 to 100,000 (FOB China), depending on features.

High-Capacity or Advanced Lines (e.g., 900–1100+ kg/h twin-screw systems, possibly with underwater pelletizing or LSP options) can cost USD 100,000 and above. When including all auxiliary equipment, it is not uncommon for a large, fully equipped system to cost in the range of USD 150,000 to 300,000. Nevertheless, Chinese machines are typically much cheaper than European machines of similar scale.

A complete bottle-to-pellet turnkey setup (including washing line + pelletizing) will cost significantly more, but here the focus is only on the pelletizing portion.

2. Factors Affecting Cost:

Several factors explain why one machine may cost more than another:

Capacity and Size:

Higher throughput machines require more materials (larger screw/barrel, bigger motors, heavier steel frames), which directly increases cost.

Extruder Type:

Twin-screw extruders are more complex and expensive than single-screw models. Due to additional components (two screws, dual gearbox, etc.), a twin-screw line may cost 1.5 to 2 times as much as a single-screw line with the same throughput.

Pelletizing Method:

Including a strand pelletizer (a simple cutter) is cheaper. Choosing an underwater pelletizer adds significant cost due to precision dies, cutters, and cooling systems, potentially increasing the price by tens of thousands.

Vacuum System:

Heavy-duty, high-capacity vacuum pump systems are more expensive. Machines with dual vacuum stations or more powerful pumps reflect higher costs.

Level of Automation:

Basic machines with manual controls are cheaper. Those with full PLC touchscreen operation, automation, and smart features cost more. For example, adding gravimetric feeding or more advanced PLC brands increases cost.

Customization and Add-Ons:

Any special customization (such as specialized filters, additional feeders) increases cost. If you request imported components (e.g., gearboxes or motors), suppliers will raise the price accordingly. Even custom colors or coatings may add a small amount (though usually minimal).

Construction Materials:

Standard PET machines come at standard cost. If you need special wear-resistant materials (e.g., for pelletizing PET with glass fibers, requiring bimetal barrels and specially coated screws), costs rise due to pricier alloys or treatments.

Brand and Support:

More established brands with strong support may charge a premium, partly for guaranteed service and quality. In the long run, this may save costs through greater reliability. Essentially, you may pay extra for a company known for superior after-sales service—like an insurance fee.

Shipping and Import Costs:

While not part of the machine’s price, budget must account for shipping (which can cost thousands of dollars depending on distance). Import duties vary by country—plastic recycling machines may be subject to tariffs or taxes. Check your local HS code rates (plastic extruders/pelletizers typically fall under HS Code 847720).

|

3. Operating Costs:

|

4. Hidden Costs to Consider:

|

Straight Answers to the Questions You Might Be Hesitant to Ask

Raw Material Quality: Start with clean, properly sorted PET flakes.

Moisture Control: Dry the flakes as much as possible before extrusion.

Temperature Profile & Residence Time: Follow recommended temperature settings—hot enough to melt PET, but not overheated or held longer than necessary.

Filtration & Purity: Use proper melt filters to remove contaminants.

Avoid Thermal Degradation: Besides temperature control, minimize oxygen exposure while the PET is molten.

Boxin offers a set of after-sales services to support international customers. These typically include:

Installation & Commissioning

Training

Documentation

Warranty Service

Spare Parts Support

Remote Support

Upgrades & Expansions

On-site Troubleshooting Visits

Quick Q&A Resources

★ Rated 4.9/5 based on 68 client reviews for Boxin PET Pelletizing Technology.

One of the key reasons to invest in a PET flake pelletizing machine is the wide range of applications for the resulting recycled PET (rPET) pellets. Once PET bottle flakes are converted into pellets, these can be processed in many manufacturing operations just like virgin plastic resin.

A common use of recycled PET pellets is for making plastic sheets and films. rPET pellets can be fed into sheet extrusion lines to produce thermoformable sheets.

These sheets are then used to make items such as clamshell containers, trays, or blister packs (especially for non-food or secondary packaging). Many packaging companies mix a percentage of rPET pellets with virgin PET to produce sheets without sacrificing quality.

In fact, pellets from high-quality PET pelletizing lines can be blended with virgin material at ratios up to ~30% to make new PET preforms (for bottles) or sheets without quality compromise. For example, PET waste from preform production (offcuts, rejects) can be re-pelletized.

One of the largest markets for recycled PET is the fiber industry. rPET pellets can be melted and extruded into fibers or filaments, essentially forming polyester yarns. These are used to make textiles, garments, carpets, and industrial fibers.

In fact, a significant portion of globally recycled PET is used to make polyester staple fiber (PSF), which is used as fiberfill (e.g., for pillows, jackets) or spun into fabric yarns. Recycled PET is also used in polyester filament yarns for sportswear or sewing threads.

rPET pellets for fiber don’t require the high IV of bottle-grade PET, so even slightly degraded materials can be used—making it a forgiving and high-volume application.

Another major application for rPET pellets is the production of PET strapping (packing tape). PET strapping is a strong binding material used to secure packages or pallets. It is made entirely from recycled PET.

In many industries, PET strapping has largely replaced steel strapping, and using recycled pellets is cost-effective. Similarly, rPET pellets can be used to manufacture geotextiles, nonwoven fabrics, and other industrial products.

The holy grail of PET recycling is producing new food-grade bottles from recycled material. This is possible but requires additional purification or polycondensation steps (such as SSP or newer LSP processes) to ensure the pellets meet strict safety and IV standards.

Many large recyclers produce food-grade rPET pellets, which beverage companies blend with virgin resin to make new water bottles, soda bottles, etc. If the pelletizing machine is part of a “bottle-to-bottle” recycling line, the pellets it produces are fed into a Solid-State Polycondensation (SSP) reactor to enhance IV and remove trace contaminants—resulting in food-contact certified pellets.

In recent years, technologies like vacuum-assisted extrusion and LSP (Liquid State Polycondensation) have emerged, allowing food-grade pellets to be produced directly during pelletizing, making bottle-to-bottle recycling more efficient.

PET is less commonly used for injection molding into durable goods (due to its properties and drying requirements), but there are use cases. For example, recycled PET can be blended with polycarbonate or used in certain PET alloys for molded parts.

More specialized applications include PET foam board production or as feedstock for 3D printing filaments. While PLA is more common in 3D printing, PETG and PET are also used, and recycling scrap into filament is an emerging niche market. PET foams (e.g., PET-based foam cores for composite panels) are also being developed with recycled content.

Beyond mechanical reuse, pelletized PET can serve as feedstock in chemical processes. For example, some rPET pellets are sold to companies that chemically convert PET into polyols (used in polyurethane foams) or break it down into monomers.

Recycled PET pellets can be used as part of mixed plastic compounds. For example, PET can be blended with polycarbonate (PC) to make certain engineering plastics. Some compounds of PET with other plastics (sometimes called PET alloys) use recycled PET as the base resin.

The broad usability of pellets highlights why pelletizing is a critical final step in PET recycling: it transforms waste flakes into standardized raw material that can serve many manufacturing processes, thereby adding greater value to the recycled material.

| Parameter | Specification Range |

| Capacity Range | 300 kg/h – 2000 kg/h (customizable) |

| Applicable Material | Washed and dried PET bottle flakes |

| Final Pellet Size | Ø 3–5 mm (adjustable) |

| Moisture Content | ≤ 0.5% |

| Melt Flow Index (MFI) | 0.6 – 1.0 g/10min (suitable for bottle-to-bottle use) |

| Voltage | 380V / 50Hz (customizable available) |

| Operation Mode | Fully automatic PLC control + manual monitoring |

| Labor Requirement | 2–3 operators per shift (depending on configuration) |

Transform contaminated waste bales into high-value, commodity-grade flakes. Boxin Machinery is not just an equipment manufacturer; we provide a turnkey engineering solution from "De-baling" to "Finished Packing," ensuring your final product meets Fiber-Grade or even Bottle-to-Bottle (Food Grade) standards.

Finding the right partner is critical. Here is how we ensure your success: