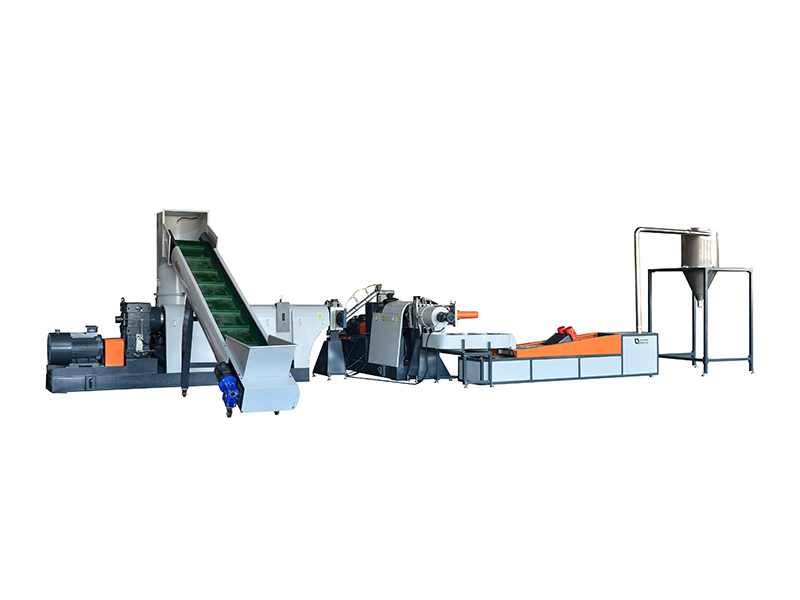

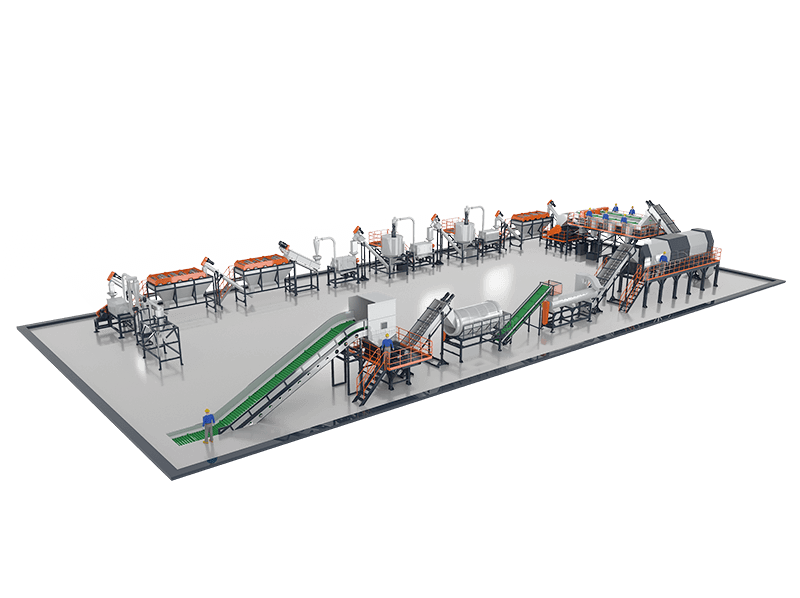

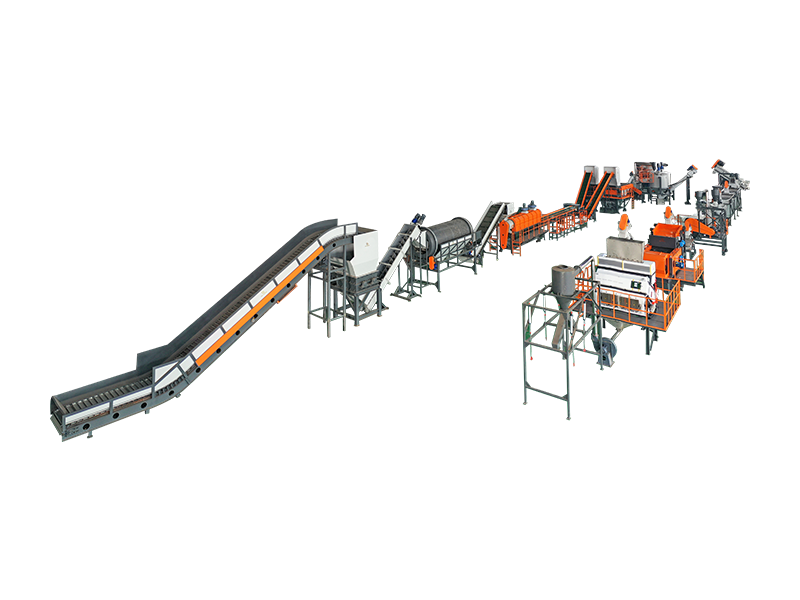

Types of PP Woven Bag Washing Lines

Standard Process Of PP Woven Bag Washing Line

|

|

|

|

|

1. Feeding & Size Reduction System

The process typically begins with a belt conveyor feeding system, which delivers compressed bales or loose PP bags into a heavy-duty shredding chamber. The machine can be a twin-shaft shredder or a dedicated crusher equipped with multiple rotating blades. The goal is to cut the bags into smaller pieces or flakes (usually about 50–100 mm) to facilitate washing.

Key Features:

Boxin Machinery has developed an enhanced rotor and blade system (using cryogenically treated D2 steel blades) that can directly shred PP bags without the need for a pre-shredder.

This innovation streamlines the production line, reduces the total number of machines (saving space and maintenance costs), and still produces uniform flakes suitable for effective washing.

|

2. Sink-Float Separation Unit

Once the material size is appropriately reduced, it typically enters a float-sink tank (also known as a flotation washer).

This is essentially a water tank where plastic flakes are mixed with water and separated based on density. Polypropylene is lighter than water, so the PP flakes float, while heavier contaminants (such as clumps of dirt, metals, glass, or high-density polymers) sink to the bottom.

Key Features:

Optional Additional Feature: High-Efficiency Residue Recovery — Boxin offers advanced separation systems that not only remove heavy particles but also recover residues (such as powders) for reuse or easier disposal.

|

3. High-Speed Friction Washer

After or between flotation tanks, the next critical component is the friction washer.

This machine is a cylindrical chamber equipped with a rapidly rotating shaft and paddles or brushes, causing the plastic flakes to rub against a screen and against each other.

The friction washer typically sprays water during rotation to thoroughly remove dirt, glue, and surface contaminants. The process often includes two stages of friction washing: a primary friction wash after the first flotation tank, and a secondary friction wash following rinsing.

Key Features:

Dual-stage friction design for enhanced cleaning intensity

Constructed with wear-resistant materials for long-term durability

Supports continuous high-speed operation without clogging or downtime

|

4. Hot Washing System

The hot washing system is an optional component in a polypropylene woven bag production line. Not all recycling operations require hot washing—if your input bags are relatively clean or only dusty, cold washing may suffice. However, if the bags contain specific contaminants, adding this equipment can be beneficial.

|

|

|

|

|

|

5. Dewatering & Drying System

Efficiently reduces moisture content of processed woven bag flakes to below 5%, enabling faster packaging and ensuring consistent quality for downstream pelletizing.

Key Features:

High-speed centrifugal dewatering combined with hot air pipe drying

Delivers stable operation, even under high throughput

Prevents moisture-related quality issues in subsequent extrusion or granulation stages

|

6. Finished product display

|

|

|

Simplified Process Flow:

Conveyor → Crusher (Granulator) → Friction Washer → Float Washer → Friction Washer → Friction Washer → Float Washer → Dewatering Machine + Pipeline Drying or Direct Use of Plastic Squeezer Dryer

Special Note:

In the field of woven bag cleaning and recycling, most equipment suppliers usually adopt a two-stage pre-treatment structure of "shredding + crushing" due to its high material strength, easy entanglement, and heavy structure. By first coarse crushing and then fine crushing, the load pressure and blade loss caused by the crusher directly processing woven bags can be avoided.

Boxin takes a different approach: based on our 20+ years of experience in recycling equipment manufacturing, we have developed a self-developed enhanced crushing chamber structure, knife shaft system and customized tool materials (D2 + cryogenic treatment), which achieves efficient and stable crushing without pre-shredding, which not only simplifies the entire line system and reduces the equipment failure rate, but also optimizes the user's maintenance cost.

Of course, we always maintain the honesty of technology:

- Direct and efficient crushing reduces the complexity of the equipment structure, but places higher requirements on the durability of the blade.

- The average sharpening cycle of our blades is slightly faster than the "shredding + crushing" mode by about 20% (but much lower than similar crushers in the industry).

- Shredding + crushing cannot completely avoid tool maintenance, but only relatively reduce the frequency.

So we insist on recommending the most suitable solution based on the characteristics of the customer's raw materials and operation and maintenance habits, rather than forcing standardization.

No matter which structure you prefer to use, we can provide mature and field-proven configuration solutions and support on-site proofing tests or structure demonstrations to help you make a safe choice.

It is recommended that you visit the other party's factory before choosing a cooperative supplier to see if they have the following capabilities:

Whether they have self-developed core crushing components (knife shaft, blade, crushing chamber);

Whether they can display the actual machine disassembly or spare parts display;

Whether they support adjusting the knife gap and angle according to different bags;

These details often determine the performance and life of the equipment in actual operation.

Customized Solutions and Services Offered by PP Woven Bag Washing Line Manufacturers

|

Tailored Machine Configurations:

Recycling equipment is not one-size-fits-all. A good manufacturer will inquire about your raw material details, level of contamination, expected capacity, and final product requirements before finalizing the design of the washing line. Based on these factors, they may adjust the process flow or add specialized components. For example, if your PP bags are especially tough or thick (such as certain chemical bulk bags), the supplier might upgrade the crusher motor power or recommend adding a pre-shredding stage to ensure smooth processing.

|

|

Pilot Testing and Material Analysis:

Some top-tier companies, such as Boxin Machinery, offer sample material testing at their facilities and design the production line accordingly. Boxin emphasizes that they do not impose standard solutions without considering the customer’s specific material. Instead, they prefer to recommend the most suitable configuration based on real-world tests and the client’s operational habits. This level of customization ensures that you receive machinery truly suited to your needs, rather than a generic design that may underperform if your material is unusual.

|

Choosing a Reliable Chinese Supplier or Company for PP Woven Bag Washing Lines

Selecting the right supplier (or manufacturing company) for your PP woven bag washing line is just as critical as choosing the right equipment. China is a major hub for plastic recycling machinery, with dozens of companies offering similar-looking washing lines. However, these suppliers can vary widely in terms of quality, technical capability, and reliability.

Verify Manufacturer Experience and Specialization:

Look for companies with a strong track record in plastic recycling machinery, especially washing lines. Established manufacturers often proudly showcase their history (e.g., over 20 years in the industry) and will provide case studies of previous projects.

Evaluate Technical Capability and Innovation:

A key differentiator is whether the supplier has its own R&D technology or simply copies generic designs. While many machines may look similar, subtle design choices (such as in crushers) can greatly impact performance. For instance, ask whether the supplier has designed their woven bag crushing system in-house or outsourced it.

Check Core Component Quality:

Carefully examine the core components used or manufactured by the supplier. Reliable companies use high-quality materials for these parts—such as alloy tool steel blades with proper hardening or proprietary friction washer designs. As mentioned earlier, ask whether they have independently developed key crushing components (shafts, blades, chambers), and whether they can show you these parts.

Factory Visits or Virtual Inspections:

If feasible, visiting the supplier’s factory in China is one of the best ways to verify reliability. You can see the build quality firsthand: inspect the thickness of the steel used, the assembly standards, and even witness a test run. As recommended by the Boxin team, a factory visit is highly encouraged to confirm whether the supplier truly has the capabilities they claim.

FAQ & Expert Tips: Most Common Buyer Questions

Straight Answers to the Questions You Might Be Hesitant to Ask

1. What Capacity PP Woven Bag Washing Line Do I Need for My Operation?

Determining the right capacity depends on how much material you plan to process daily or monthly. You should assess how many kilograms of PP bags you typically recycle per day. It's wise to choose a washing line with a slightly higher capacity than your current needs to accommodate future growth or demand surges.

2. Can a Washing Line Handle Different Types of Plastic Waste at the Same Time (e.g., Mixed PP Woven Bags and PE Film)?

While some washing lines are marketed as multi-purpose (capable of handling both film and woven bags), in practice, simultaneously processing mixed plastics and achieving high-quality output is challenging. Technically, it’s possible—washing lines can be configured to handle both PP and PE film due to similar recycling processes. However, the best approach is to invest in separate lines or batch process the materials (cleaning the system when switching).

3. Do Tough PP Woven Bags Clog Machines or Lower Efficiency?

PP woven bags are known for their tough fibers, which have historically caused clogging or shaft wrapping issues. Most modern systems have addressed this with pre-shredding steps or advanced blade designs. A common industry solution is a “pre-shredder + secondary crusher” configuration to reduce stress on the equipment.

4. Is Hot Water Washing Necessary for Cleaning PP Woven Bags?

It depends on the level of contamination on your bags and the cleanliness required for your final product. Hot washing (using heated water, possibly with detergents) isn't always essential, but it can be highly effective for certain contaminants.

5. What Is the Typical Cost of a PP Woven Bag Washing Line?

As mentioned, the cost of a PP woven bag washing line ranges from as low as $30,000 to over $200,000. Many mid-range systems cost between $60,000 and $100,000.

6. Can the Washed Material Produce High-Quality Pellets for Export Markets?

The key to pellet quality lies in the cleanliness and consistency of the flakes, along with a solid pelletizing process (including proper melt filtration, degassing to remove moisture or volatiles, etc.). If the washed flakes are extremely clean (free from dirt, minimal odor, moisture content below 1%), you can produce bright, uniform pellets with properties nearly as good as virgin PP. These pellets can be used to make new woven bags, household items, and more—often blended with some virgin material if needed.

EN

EN

English

English 简体中文

简体中文 Русский

Русский España

España عرب .

عرب .