How it works—big picture:

material enters an extruder where heat and shear melt HDPE and homogenize color/additives. The melt is de-gassed to remove moisture and volatiles, filtered to trap fines/metal/labels, then pelletized (cut into granules) and dried/cooled. The plant’s control philosophy is to keep melt pressure, temperature, and throughput stable so the pellet’s geometry and properties remain within spec.

Why pelletize instead of using flakes directly?

Processability: pellets meter and melt uniformly, enabling tighter dimensional control in molding.

Value capture: pellets command higher prices and broaden your sales channels.

Logistics: pellets flow, convey, and store more efficiently than irregular flakes.

Blending & property tuning: during extrusion you can tune pigment, stabilizers, or re-balance melt flow for target applications.

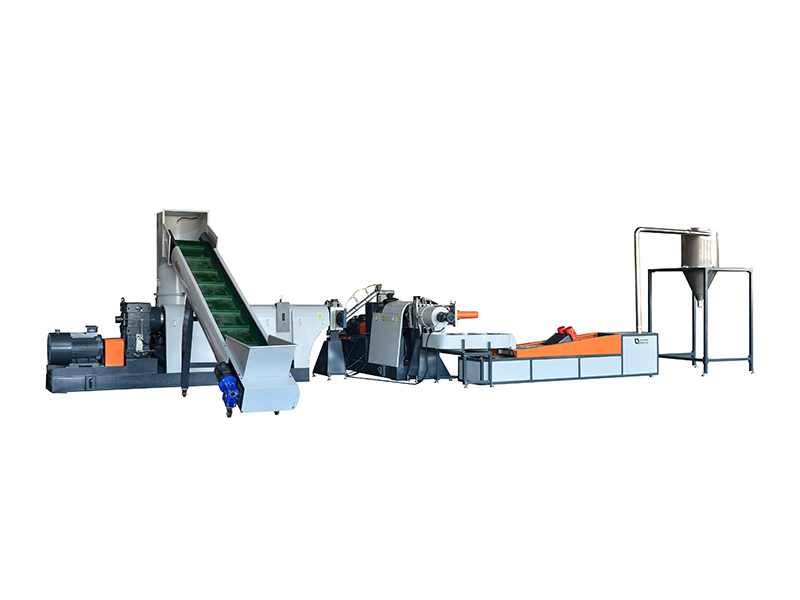

Double Stage Pelletizing Machine Process

|

|

|

|

|

Feeding System

Transfers HDPE or mixed plastic flakes smoothly and continuously to the first-stage extruder for melting and processing.

Key Features:

Anti-bridging structure design prevents material clogging or buildup

Auto-buffer feeding control ensures steady throughput and accommodates various material types and densities

|

Primary Extrusion System

Performs the first-stage melting and homogenization of HDPE flakes while removing coarse impurities from the material stream.

Key Features:

Equipped with a high-torque screw system

Custom-designed flow channel geometry optimized for HDPE material behavior

Ensures stable melt pressure and consistent material feed into the secondary extruder

|

Vacuum Degassing Module

Eliminates residual water vapor and volatile organic compounds (VOCs) from the HDPE melt to ensure low-odor, high-quality pellet output.

Key Features:

Dual-stage vacuum ports for enhanced degassing performance

Effectively removes gases, fumes, and odors generated by contaminated materials

Helps prevent yellowing, voids, and surface defects in final pellets

|

Dual-Station Screen Changer

Intercepts solid impurities in real time to ensure stable and uninterrupted extrusion, even with contaminated HDPE feedstocks.

Key Features:

Hydraulic quick-change design for fast, tool-free screen replacement

Non-stop operation during screen changes — no downtime, no material loss

Prevents pressure fluctuations and improves melt consistency

|

|

|

|

|

|

Secondary Extrusion System

Refines the plastic melt after the primary stage, enhancing melt purity, pressure stability, and pellet uniformity before pelletizing.

Key Features:

Integrated precision temperature control and real-time pressure feedback

Delivers stable extrusion flow, improving pellet size consistency and overall product quality

Especially effective for high-demand applications requiring tight quality control

|

Strand Pelletizing System

Converts the extruded plastic strands into uniform pellets through a straightforward, reliable cutting process.

Key Features:

Simple mechanical structure with low investment and maintenance costs

Ideal for a wide range of recycled materials, especially in standard-grade production

Optional pelletizing methods available:

Water ring pelletizing

Underwater pelletizing

|

Dewatering + Vibratory Screening Unit

Combines centrifugal dewatering and vibratory screening to deliver clean, low-moisture pellets ready for high-quality downstream processing.

Key Features:

Efficiently removes surface moisture, powder residues, and oversized or undersized granules

Improves pellet cleanliness and consistency

Final pellets are suitable for injection molding, film blowing, and other precision applications

|

Final Product Collection System

|

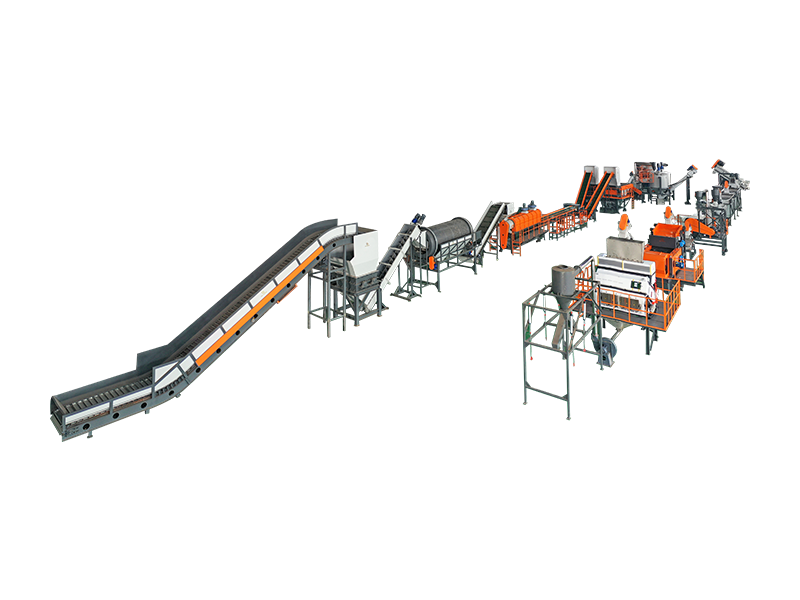

Line Types & Key Options: Single-Stage vs Two-Stage; Strand vs Water-Ring vs Underwater (How to Choose)

A. Extrusion architecture: single-stage vs two-stage

Single-stage (one extruder): generally suited to clean, low-contamination hard HDPE (e.g., in-house scrap or well-washed flakes). Lower capex/footprint and faster changeovers.

Two-stage (two serial single-screw extruders, or single-screw followed by another single-screw): designed for washed but variably contaminated flakes—think label glue, paper dust, oils from drums/containers. The first stage plasticizes and performs coarse de-gassing/filtration; the second stage refines the melt, adds stronger vacuum de-gassing, and performs finer filtration. This architecture improves pellet purity, reduces voids/odor, and stabilizes pressure for uniform cutting.

B. Pelletizing method: strand vs water-ring (hot-die face) vs underwater

Strand pelletizing: melt exits the die in strands, passes through air/water cooling, then a strand cutter chops to pellets. It’s capex-friendly, easy to observe, and robust for rigid HDPE flakes; changeover and troubleshooting are straightforward. Trade-off: more operator touch and sensitivity to strand stability at very high throughputs. Multiple industry explainers call strand systems the most cost-effective, widely applicable baseline, especially for many recycled streams.

Water-ring (hot die face): pellets are cut at the die face and immediately carried in a water ring. It yields rounded, visually attractive pellets, automates handling, and is popular for films and light flakes; it can also serve rigid HDPE where roundness and bagging aesthetics matter.

Underwater pelletizing: cutting occurs submerged right at the die; excellent thermal control, tight size distribution, and scalability to very high throughputs, but higher capex/maintenance and stricter water system management. Vendors and technical articles note it for premium pellet quality and efficiency at the top end.

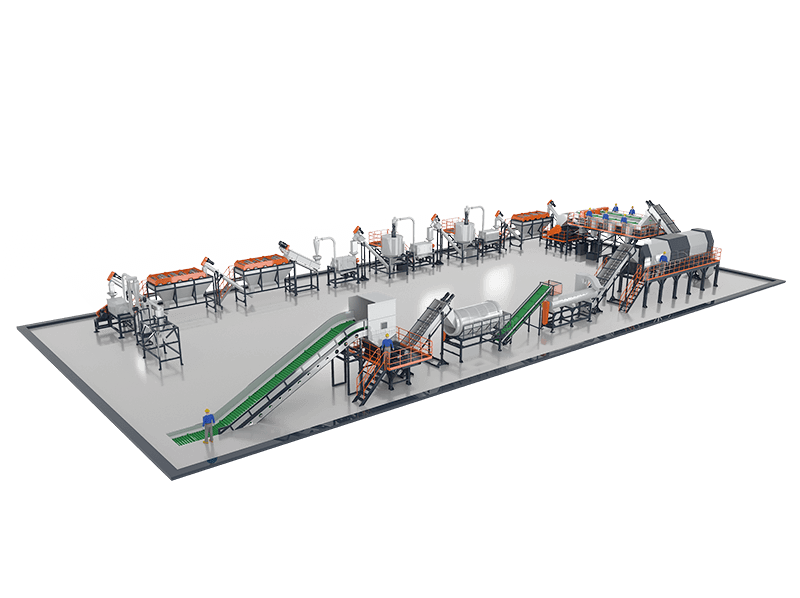

Custom OEM Services & Solutions

As a professional PET bottle washing line manufacturer in China, Boxin Machinery stands out in the industry with its OEM and custom engineering capabilities. For global B2B buyers, the ability of the system to adapt to local raw material conditions, regulatory requirements, and factory layout is a key factor in procurement decisions.

|

Tailored Engineering

|

Pre-Sales Testing & Consultation

|

Global Installation & Training Services

|

After-Sales Technical Support

|

-

Raw material assessment (via sample analysis)

-

Customized process flowchart and plant layout (CAD drawings)

-

Modular equipment selection based on buyer priorities (cost, output, water resource constraints, etc.)

-

Turnkey delivery including steel platforms, electrical wiring, piping, and control cabinet configuration

|

Clients can send PET bottle samples to Boxin’s R&D center for small-scale washing and contamination analysis. Based on the results, Boxin recommends a suitable system configuration considering:

Contamination type (glue, oil, label type)

Color ratios (clear, blue, green, or mixed)

Moisture levels and target IV retention of flakes

|

Boxin offers on-site installation, commissioning, and operator training, as well as remote installation support via video calls. Buyers will receive:

|

Boxin guarantees:

-

One-year full machine warranty

-

24-hour technical response

-

48-hour dispatch for critical spare parts

-

Lifetime maintenance guidance

|

|

Industry Knowledge Extension :::

More information about HDPE pelletizing Production Line

|

|

|

Configurations & Economics: Example Specs, Capacity Planning, Energy & OPEX Levers (with a Boxin Two-Stage Reference Build)

A practical way to converge on spec is to anchor to a known, fielded configuration and then add/remove options.

Reference build (two-stage HDPE flakes line with strand pelletizing):

A representative architecture includes: anti-bridging feeding, primary single-screw for melt/homogenization, dual-port vacuum de-gassing, dual-station hydraulic screen changer, secondary single-screw for melt polishing and pressure stability, strand pelletizer (with options to shift to water-ring or underwater), followed by centrifugal dewatering + vibratory screening and silo. Boxin’s two-stage HDPE pelletizing page outlines this modular setup and explicitly supports choosing among strand / water-ring / underwater heads.

Capacity planning:

Nameplate rates commonly scale from ~200–1000+ kg/h per line for rigid HDPE in mid-market factories, with higher rates available on premium systems; vendors publish 800–1000 kg/h builds and 1000 kg/h film lines as reference points (rates vary with mesh, venting, head type, and operator practice).

When in doubt, size for 80–85% of quoted nameplate at your target mesh and dual-vent set-up; reserve the top 15–20% for seasonal contamination spikes, label glue events, or extra-fine filtration.

Energy/OPEX levers that move your ROI:

De-gassing done right (pump sizing + vent geometry) reduces rework/off-grade (odor/voids).

Screen strategy (mesh and swap cadence) optimizes pressure and kWh/kg.

Pelletizer choice influences labor (strand has more operator touch; underwater raises capex/maintenance but can scale efficiently).

Automation (recipe set-points, auto-buffer feeding) smooths load, preserving cutter stability and reducing strand breaks.

Upstream washing quality cuts fines/labels load—pelletizers don’t fix poor washing; they magnify it in OPEX.

Frequently Asked Questions

Straight Answers to the Questions You Might Be Hesitant to Ask

My raw material is mixed HDPE regrind with some impurities. Which type of pelletizing line is suitable?

It is recommended to use a two-stage pelletizing line. Compared to a single-stage system, the two-stage configuration offers stronger degassing and filtration capabilities, making it more effective for handling materials with high impurity levels and strong odors. This ensures the purity and appearance consistency of the final pellets.

I want the final pellets to be exported overseas, with no odor and no bubbles. Can Boxin’s equipment meet these requirements?

Absolutely no problem. We can customize a system with dual degassing zones, dehumidifying dryers, and a precision filtration unit. Our solutions have already been successfully adopted by multiple export-grade clients. The pellets produced are high in cleanliness, color-stable, and fully meet the requirements for high-end recycled material exports.

I’ve heard that two-stage machines are difficult to maintain. How is the service life? Do they clog frequently?

The Boxin two-stage system has been structurally optimized in several key areas:The strand water tank features an anti-wrapping design and high water level, ensuring smoother discharge;The air knife drying system delivers more thorough drying, effectively preventing strand blockage;The die head and pelletizing system have undergone extensive real-world testing and support a blade lifespan of over 10 tons, significantly reducing maintenance frequency

I’m not very familiar with how to choose a pelletizing method. What are the differences?

Strand pelletizing is suitable for bottle flakes and drum regrind. It features a simple forming process and is easy to observe and maintain.

Water ring pelletizing is suitable for film and lightweight flakes. The pellets are round and visually appealing, making them ideal for commercial sale.

Underwater pelletizing (optional) is suitable for high-precision pelletizing requirements. It features a fully enclosed system that provides more uniform pellet cooling and higher dimensional accuracy.

EN

EN

English

English 简体中文

简体中文 Русский

Русский España

España عرب .

عرب .