Pelletizing Extruder Feedstock

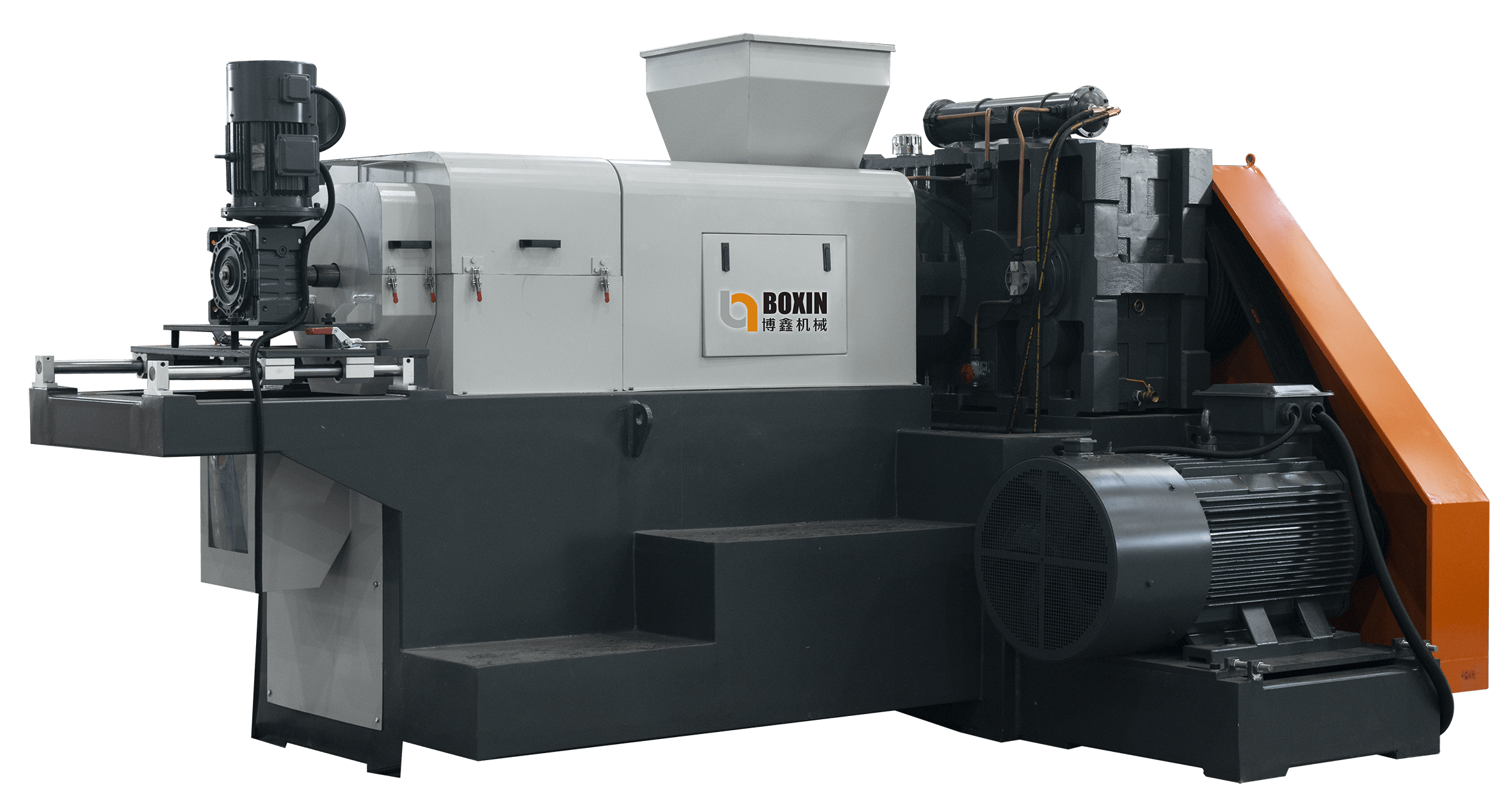

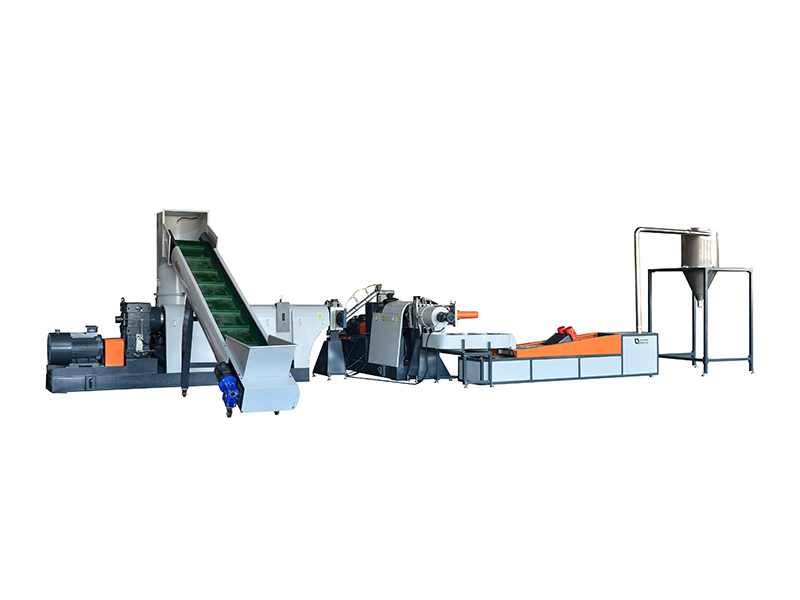

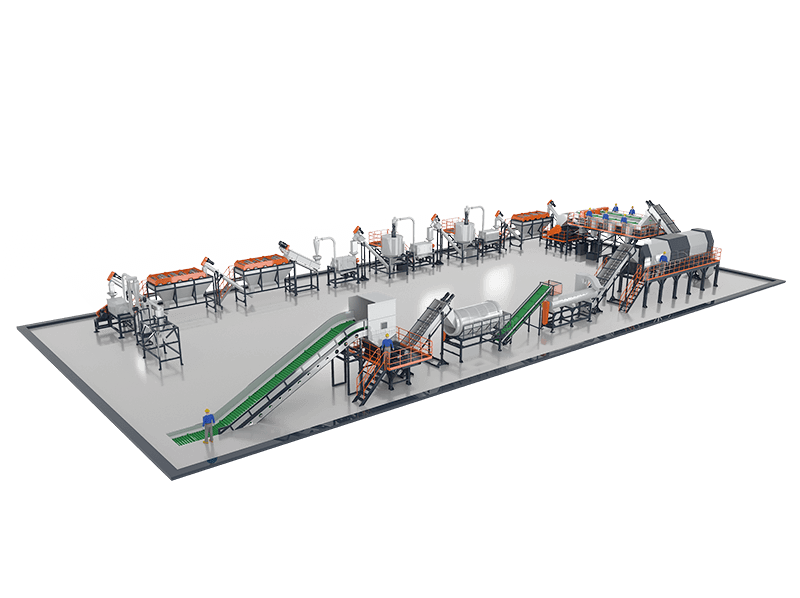

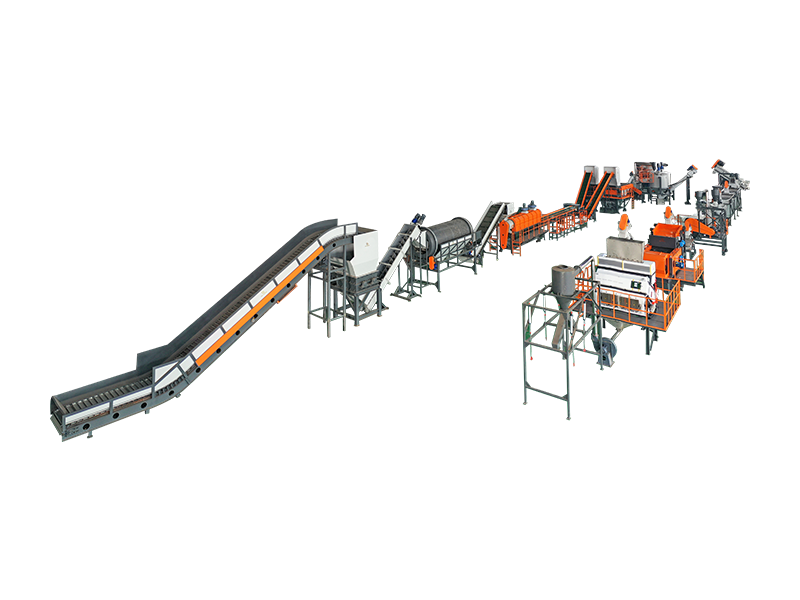

In most recycling operations, these granules serve as intermediate feedstock for pelletizing extruders (single-screw, double-stage, or similar). The extruder melts and filters the material, producing uniform, high-quality pellets. These final pellets are cylindrical or spherical, consistent in size, fully melted, and filtered to remove residual impurities (e.g., paper or metal). They are suitable for sale or direct manufacturing use. The dry, dense granules are an ideal feedstock—unlike wet, fluffy films that cause steam, feeding issues, and low efficiency.

EN

EN

English

English 简体中文

简体中文 Русский

Русский España

España عرب .

عرب .