LDPE Film Washing Recycling Line

LDPE Film Washing Line – An efficient, turnkey recycling system for washing and drying contaminated plastic films (LDPE, LLDPE, etc.), delivering high-quality, reusable plastic flakes.

Web Menu

Product Search

Exit Menu

LDPE Film Washing Line – An efficient, turnkey recycling system for washing and drying contaminated plastic films (LDPE, LLDPE, etc.), delivering high-quality, reusable plastic flakes.

Designed with robust, industrial-grade components, this washing line reliably handles high contamination loads (up to 70–80% impurities) without clogging or excessive wear. Wear-resistant shredding and cutting units protect against damage from sand and debris, ensuring continuous operation even in demanding applications. The process is arranged in multiple washing stages – including pre-washing, cold and hot water washing, and intense friction scrubbing – so that each type of contaminant (from large grit to water-soluble residues) is effectively removed in turn.

With over a decade of expertise in plastic recycling machinery, Boxin has engineered this LDPE film recycling line for easy operation and maintenance. The entire line is automatically controlled, with interlocked modules that coordinate feeding, washing, and drying. This not only maximizes throughput but also ensures stable performance and operator safety. Additionally, a circulating water filtration system is used to minimize fresh water usage and maintain cleaning efficiency, making the process more eco-friendly and cost-effective.

After washing and drying in the line, the plastic film flakes come out clean and with moisture content under 5%. The dry, uniformly sized flakes can be fed directly into pelletizing extruders to produce granules, or they can be sold/used as-is for various plastic manufacturing. Production capacity is flexible (standard models from 300 kg/h up to 3000 kg/h), and each line can be customized to match your specific throughput and cleanliness requirements.

Used for breaking down large bales or bundles of film and bulky waste into smaller pieces. This is especially useful for tightly packed agricultural films or PP jumbo bags, allowing downstream equipment to handle the material more easily.

Further cuts the film pieces into small, uniform flakes (typically 30–50 mm) while mixing with water for initial cleaning. The wet crusher not only downsizes the material for better washing efficiency but also performs a pre-wash by removing some dirt as the film is cut.

A high-speed washing unit that vigorously scrubs the film flakes with water. The friction washer’s rapidly rotating paddles abrade and shake off stubborn contaminants (like caked mud, adhesive residue, or ink) from the plastic surface. This step greatly improves cleanliness by removing fines and oils through centrifugal action.

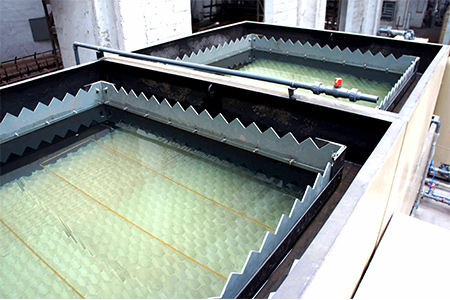

A water-filled tank where plastic flakes are immersed to separate contaminants by density. Lightweight film plastics float while heavier impurities (sand, glass, metals) sink to the bottom. The system may include conveyors or rakes to remove settled sludge. This ensures that only clean, floating plastic moves on to the next stage.

An insulated washing basin that uses heated water (and detergents if necessary) to remove grease, oil, and adhesives from the film flakes. Hot washing is crucial for contaminated films with oily residues or for removing glue (e.g. from labels or tapes on packaging films), ensuring a thorough cleansing that cold water alone cannot achieve.

A specialized drying compactor that squeezes and heats the washed film flakes to remove remaining moisture. The squeezer uses a screw press mechanism to compress the plastic while venting water, often combined with mild heating. It outputs semi-compacted plastic pellets or flakes with moisture as low as ~2%. This device not only dries the film efficiently but also slightly densifies it for easier handling or feeding to extruders.

Clean, dry film flakes/lumps ready for extrusion or direct sale. High purity ensures value in downstream applications.

(The specific configuration and number of each equipment can be adjusted to meet the contamination level and capacity requirements)

Different types of plastic film waste require tailored washing processes. Heavily contaminated agricultural films demand a more intensive setup compared to relatively clean post-industrial scraps or tough PP woven bags. Below we outline the differences and recommended configurations for various film types:

These films (often LDPE) from farmland or greenhouses come mixed with soil, sand, fertilizer residues, and organic matter.

Recommended configuration: a robust pre-treatment stage is crucial – including a pre-shredder to break up clumps and a trommel or rinsing pre-washer to remove bulk mud and stones before crushing. Multiple washing steps are needed: e.g. two or more friction washers and float tanks in series to progressively remove stubborn soil and debris. Hot washing with detergent may be employed to eliminate pesticide residues or soluble fertilizers. Enhanced wear protection (such as hardened steel blades and anti-clogging screens) is implemented to combat the abrasive sand.

This category includes factory scrap (trim film, packaging off-cuts) or clean post-consumer films like stretch wrap from warehouses, which have minimal dirt (maybe dust or labels).

Recommended configuration: the process can be streamlined – often a direct crusher (wet granulator) without pre-shredding is sufficient, since the material is already loose and not heavily contaminated. A single-stage friction wash and one float tank might suffice to remove minor impurities, followed by standard dewatering and drying. Hot washing is usually optional.

Woven polypropylene sacks and big bags are typically dirtier than packaging film but differ from soft LDPE film in texture – they are tougher, fibrous, and often come with leftover powdery contents or print ink.

Recommended configuration: a powerful pre-shredder is important to tear apart these thick bags and shake out caked contents. Since woven bags can contain sand (e.g. in cement or rice bags) and stubborn prints, the line should include an aggressive friction washing stage and at least one sink-float separation.

(For mixed film waste streams, our engineers will combine elements of the above configurations to effectively handle the blend of materials and contamination levels.)

During actual operation, LDPE film washing lines often face a few common issues (especially when dealing with very dirty agricultural films). Below are some typical bottlenecks and our technical optimization recommendations:

(By addressing the above issues with engineering solutions, Boxin’s washing lines run more smoothly, with lower maintenance needs and consistently high output quality.)

At Boxin, we understand that each client’s raw material characteristics and production goals are unique. Our team is committed to providing a fully customized recycling solution. We will tailor the equipment configuration and process flow to fit your specific needs.

Customize more suitable configuration according to your actual situation.

Design the machine layout according to your workshop drawings.

Optimal design of drainage ditch and sewage treatment.

From designing the ideal process layout to fine-tuning individual machines, our engineers work closely with you at every step. We also provide factory layout planning services – arranging the machinery to suit your workshop space and even designing optimal drainage and wastewater treatment setups. Simply share with us your raw material samples or key parameters, and our engineering team will propose the most suitable solution.

★ Rated 4.9/5 based on 92 client reviews for Boxin LDPE Recycling Solutions.

This LDPE/LLDPE film washing line is suitable for a wide range of plastic films and flexible packaging materials. Typical applications include:

Agricultural films (mulch film, greenhouse film, silage wrap) – Heavily soiled LDPE films used in farming.

Industrial packaging films (LDPE/LLDPE stretch wrap, shrink film) – Pallet wrap and packaging films from warehouses and factories.

Plastic shopping bags & wraps (LDPE/HDPE bags, trash bags, plastic wrap) – Post-consumer bag waste and packaging films.

PP woven bags & jumbo bags – Woven polypropylene sacks, big bags (raffia) and bulk bags used for grains, fertilizer, etc., often contaminated with sand or powder.

Other polyolefin films – Including BOPP and mixed PE films from recycling streams.