Converting Mixed-Color HDPE Bales into Single-Color Flakes: Boxin Turnkey Recycling Solution

Why Traditional Washing Lines Cannot Separate Mixed-Color HDPE Bales?

Most standard washing lines in existing recycling plants are unable to resolve color separation issues, primarily due to limitations imposed by the fundamental principles of fluid mechanics and material density.

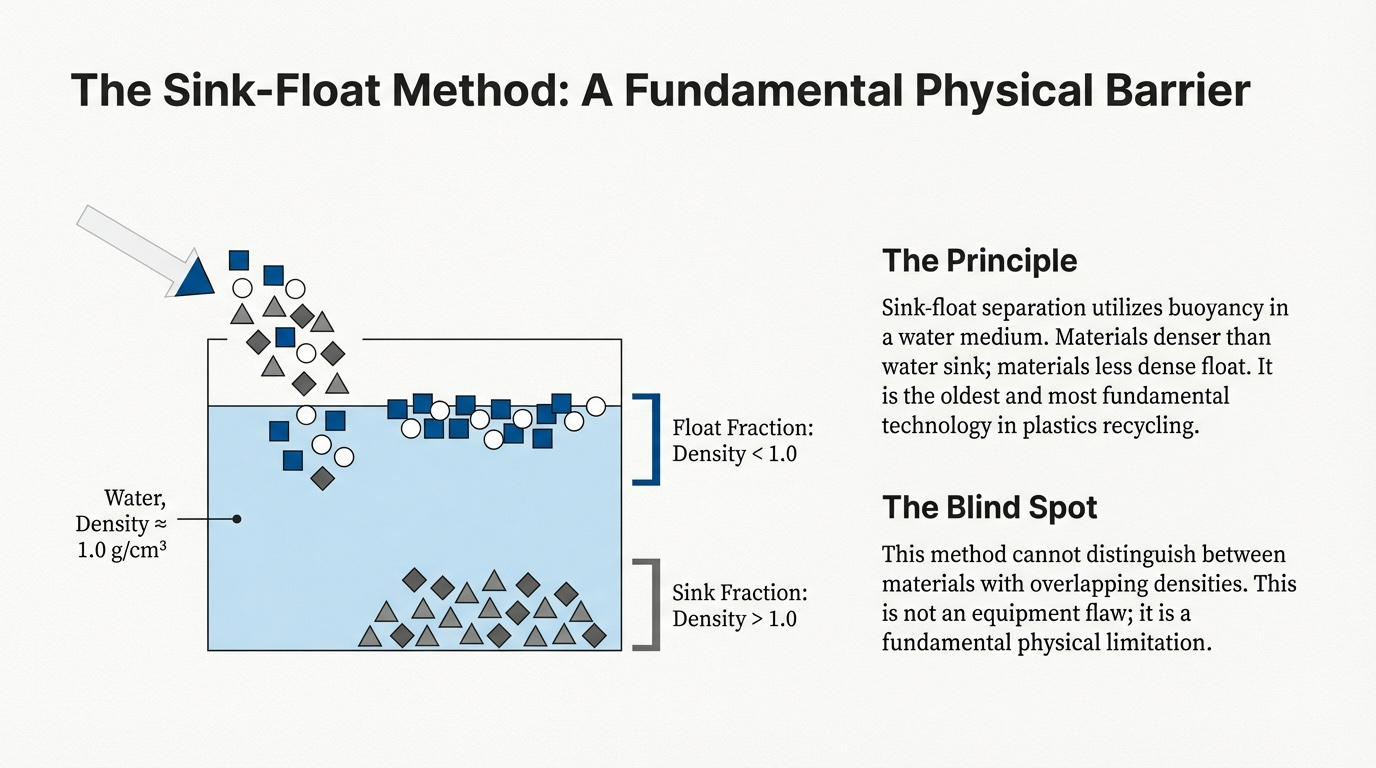

Working Principle of Sink-Float Tanks

|

Sink-float separation is the oldest and most fundamental technology in the plastics recycling industry. It utilizes the principle of buoyancy: in a water medium (density ≈ 1), objects less dense than the medium float, while those denser than the medium sink. |

In a typical HDPE recycling scenario, this physical process is used to separate the following major impurities:

-

Sink Fraction: Density > 1.0. Primarily includes heavy impurities such as PET, PVC, PS, sand, metals, and glass.

-

Float Fraction: Density < 1.0 g/cm³. Primarily includes HDPE, PP, and LDPE.

Conclusion: The sink-float method cannot distinguish between materials with overlapping densities. This is a fundamental physical limitation; regardless of equipment sophistication, this blind spot cannot be overcome as long as the process relies on density principles.

Density Consistency Across Colors

For HDPE bottles—whether white milk jugs, blue oil containers, red detergent bottles, or black shampoo bottles—the base material is Polyethylene (PE). The addition rate of pigments (masterbatch) is typically extremely low (<2%), and the masterbatch carrier is usually PE as well.

Consequently, the densities of HDPE flakes of different colors are virtually identical, falling within the 0.93–0.97 range. In water, blue flakes and white flakes experience the exact same buoyancy. The result is that while the material emerging from the floatation tank is free of stones and PET, it remains a multi-colored mixture of Mixed Rigid HDPE.

Material Density Overlap (PP and PE Interference)

Even more critical is the fact that HDPE bottles are typically fitted with PP (Polypropylene) caps. The density of PP is approximately 0.90–0.92, which is extremely close to HDPE, and both are less than 1.0. This means that in fresh water floatation, PP caps will float alongside HDPE bottle bodies.

Although PP is a valuable plastic, it is considered a contaminant when aiming for high-purity HDPE recycled material (particularly for blow-molding grade applications), as it compromises the Melt Flow Index (MFI) and mechanical strength of the final product.

Process Layout and Boxin Turnkey Solution

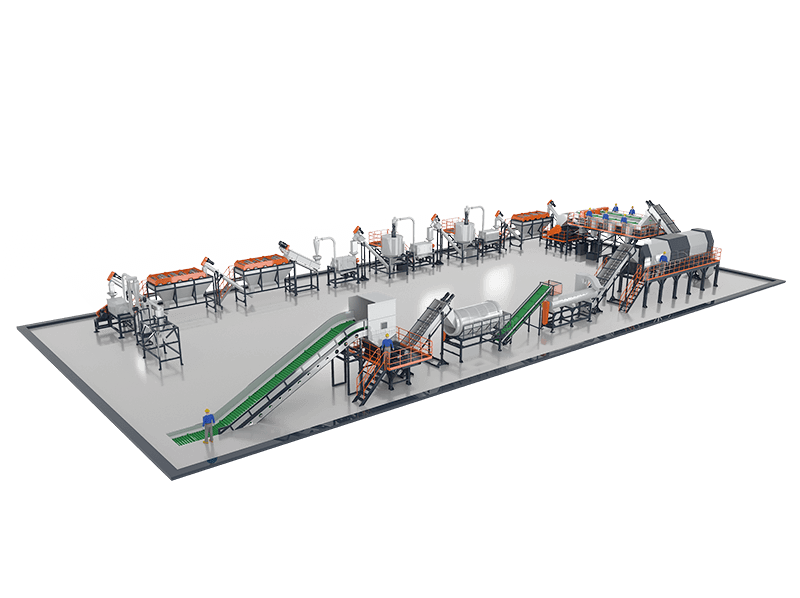

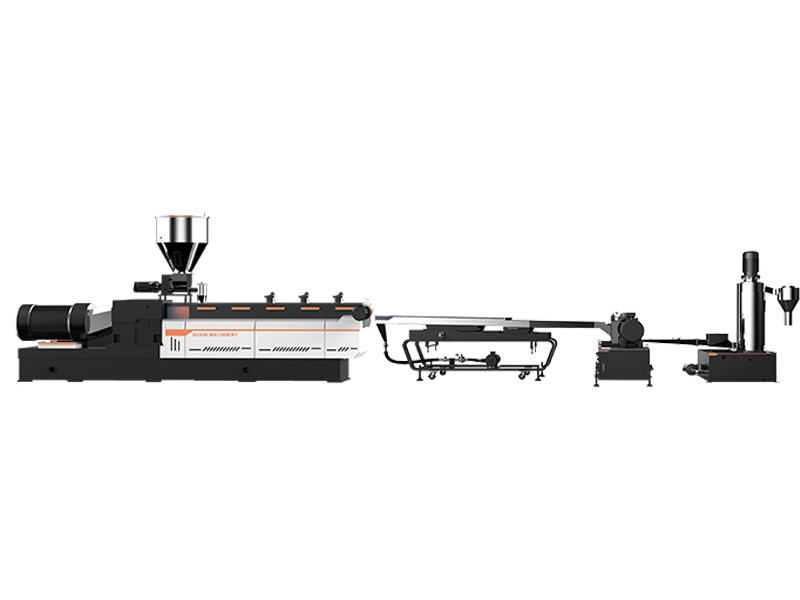

To transform mixed waste into single-color flakes, a rigorously logical and integrated production line is essential. Leveraging 20 years of industry expertise, Boxin Machinery proposes a standardized "Pre-Optical Sorting Treatment Process," ensuring that every plastic flake entering the color sorter is dry, clean, and thoroughly separated.

1. Prerequisites: Creating the Perfect Environment for Optical Sorting

In Boxin's design philosophy, three absolute conditions must be met before material enters the color sorter to ensure recognition accuracy:

-

Glue and Oil-Free: Material must undergo Hot Washing to remove all surface contaminants.

-

Absolute Dryness: Material must undergo high-efficiency Drying; moisture content must be below 1%.

-

Material Singularity: Material must first undergo density-based sink-float separation to remove heavy impurities such as metals and sinking plastics.

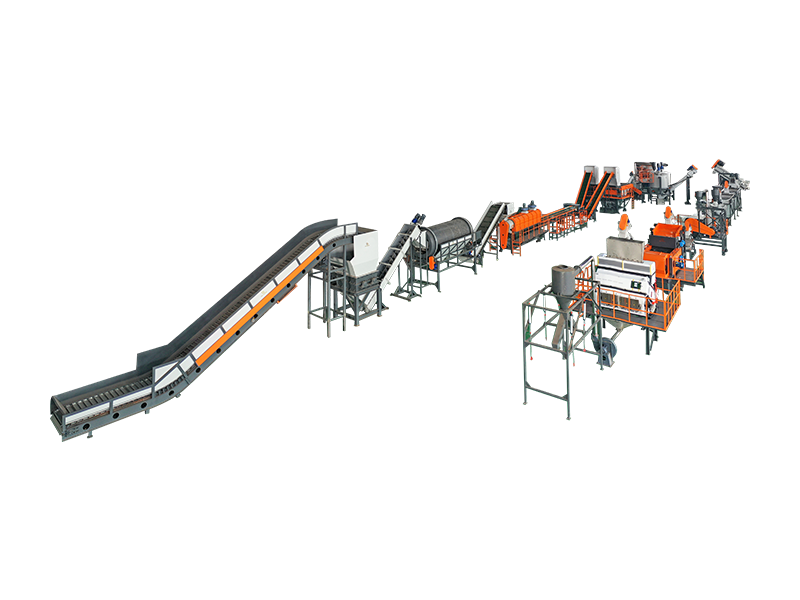

2. Recommended Layout: Boxin Standard HDPE Bottle Recycling Washing Line

The following is the process layout recommended by Boxin Machinery to maximize optical sorting efficiency:

A. Wet Crushing This is a key technical feature of Boxin. Water is injected into the crusher chamber for "wet grinding."

-

Function: Water provides preliminary cleaning and cooling, preventing HDPE from melting due to frictional overheating, while significantly extending blade life (capable of processing over 800 tons).

-

Specification: Post-crushing flake size is controlled between 12-16mm, the optimal physical dimension for optical sorting.

B. Friction Washing

-

Principle: Utilizes high-speed rotating rotor paddles (up to 2000 rpm) to generate strong centrifugal force and inter-material friction.

-

Function: Aggressively strips paper pulp, soil, and adhesive residues from flake surfaces. Boxin's friction washer is equipped with a specialized spray rinsing system; dirty water is ejected immediately through screens to prevent re-contamination.

C. Sink-Float Separation

-

Function: Utilizes density differences to thoroughly separate HDPE/PP (float fraction) from PET, PVC, and ABS (sink fraction).

-

Design Highlight: Boxin’s tanks feature large screw conveyors at the bottom for sludge removal and paddle wheels at the top to propel material, ensuring a sufficiently long and thorough separation path.

D. Hot Washing (Core Step) HDPE bottles (especially oil containers and shampoo bottles) often retain stubborn oils and strong adhesives that cold water cannot remove.

-

Importance: If not removed, these residues will yellow or blacken during drying, directly interfering with color sorter recognition; alternatively, they will carbonize during pelletizing, forming black spots and significantly downgrading the granules.

E. Rinsing & Drying

-

Rinsing: Washes away residual lye (caustic soda) and detergents, neutralizing the pH value.

-

Centrifugal Dewatering: Removes surface water via high-speed centrifugal force.

-

Hot Air Drying: Boxin employs a multi-stage pipeline hot air drying system to ensure final flake moisture content is below 1%. This is a critical prerequisite for the proper operation of color sorters.

Optical Material and Color Sorting (The Final Stage)

At this stage, the material has been transformed into dry, clean, and uniformly sized mixed-color HDPE flakes. The following step constitutes the "ultimate link" of the turnkey solution.

1. Silicone Rubber Sorting Machine (Recommended Configuration)

Mandatory if bales contain pump bottles.

-

Objective: To separate rubber/silicone from cleaner plastics.

-

Result: Retains an extremely high-purity PE material stream.

2. High-Precision Color Sorting and Purification

Color sorting, based on advanced Visible Light camera technology, is the core process for maximizing the value of mixed HDPE.

-

Sorting Logic: Adopts "Accept" (Target Preference) or "Reject" (Impurity Removal) algorithms. The system precisely identifies pixel-level color differences, retaining material defined as "target color" or forcibly rejecting "off-colors."

-

Separation Process: Taking Natural flakes as an example: When the mixed material flows through the detection zone, all non-natural colored flakes (e.g., blue, red, green, black) are precisely targeted and blown out by high-speed pneumatic air valves (Ejectors) into the reject/secondary silo. Meanwhile, natural flakes fall naturally by gravity into the accept/main silo.

-

Final Output: The main silo yields Natural HDPE flakes of extremely high purity (>99%). These high-quality flakes can directly enter the pelletizer without modification to produce recycled granules with high market premiums, widely used in blow molding or high-end manufacturing, truly achieving Closed-loop Recycling.

3. Advanced Configuration: Multi-stage Cascade Solution

For plants with high throughput seeking profit maximization, Boxin recommends a process layout utilizing a cascade of 3–5 color sorters.

-

Sorting Strategy: Abandoning the "all-in-one" approach in favor of a "step-by-step extraction" strategy. For example: The first machine extracts Natural, the second extracts Blue, the third extracts Red, and so on.

-

Benefit Analysis: This configuration simultaneously isolates multiple single-color, high-purity flakes from the same mixed feedstock. It transforms by-products, previously sold as low-value mixed scrap, into multiple high-value commodities, significantly boosting the plant's ROI (Return on Investment).

Choose Material

Related Machines

Plastic Film Recycling Washing Line

PE Film Pelletizing Machine

Heavy-Duty waste plastic crusher machine

PET Bottle Washing Line

PP Woven Bag Washing Line

HDPE Washing Line

Bottle-to-Bottle Recycling (Food-Grade PET Bottle Washing Line)

Fiber Grade PET Bottle Washing Line

EN

EN

English

English 简体中文

简体中文 Русский

Русский España

España عرب .

عرب .