Web Menu

Product Search

Exit Menu

VISION

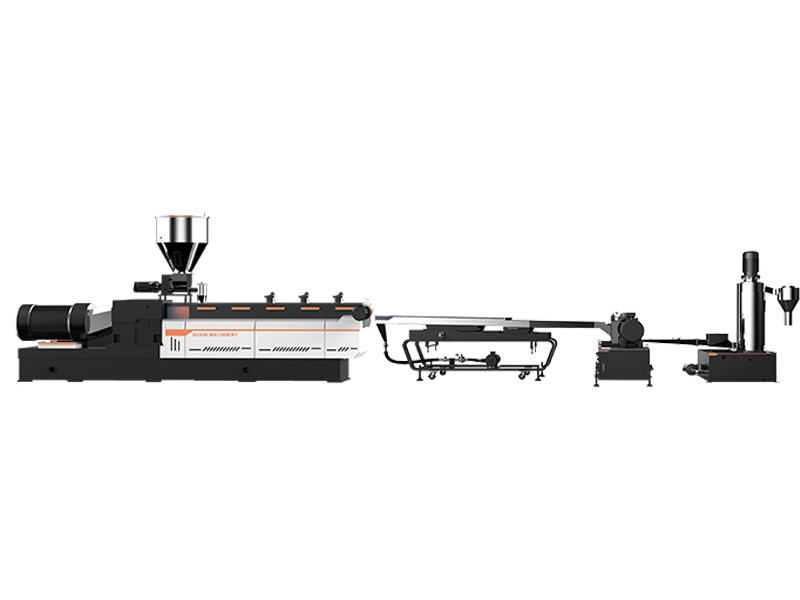

Being an industry-leading provider for plastic recycling equipment and solution by using

high quality as base and taking technical innovation as breakthrough and customer demand as orientation.

CONTACT INFO.

Copyright ©Zhangjiagang Boxin Machinery Co., Ltd.

All Rights Reserved.

ENG

ENG

English

English chinese

chinese