This represents the highest-end application of PET recycling—reprocessing used PET bottles into new bottle-grade raw materials for manufacturing new beverage bottles or food containers.

High-quality recycled PET flakes are melted, filtered, and pelletized into food-contact-grade rPET pellets, which can then be used to blow new beverage bottles—achieving a true "bottle-to-bottle" closed-loop cycle. It's important to note that regulations vary by country regarding the direct use of recycled PET in food packaging. In regions like China, for safety reasons, recycled flakes are generally not permitted for direct use in food-grade packaging. However, in Europe and North America, high-purity, food-grade PET flakes can be certified by relevant authorities and reused in new water or beverage bottles.

Additionally, bottle-to-bottle recycling also includes non-food applications, such as packaging for cleaning agents and chemical solvents, which have lower hygiene requirements. This approach significantly reduces the reliance on virgin PET resin and is considered one of the most environmentally sustainable recycling models.

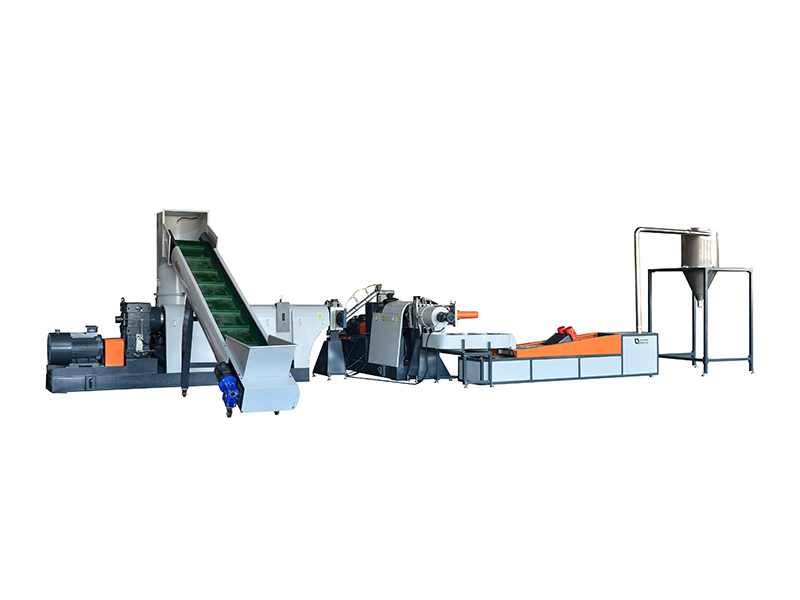

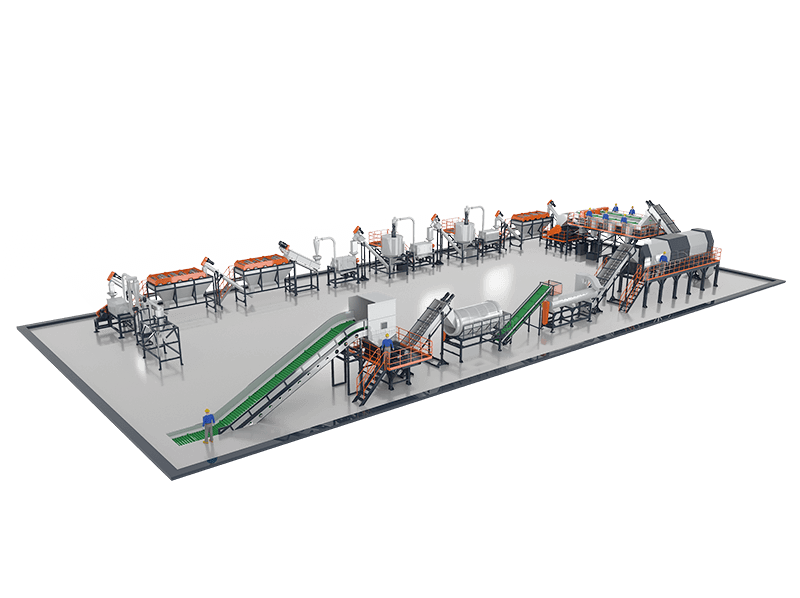

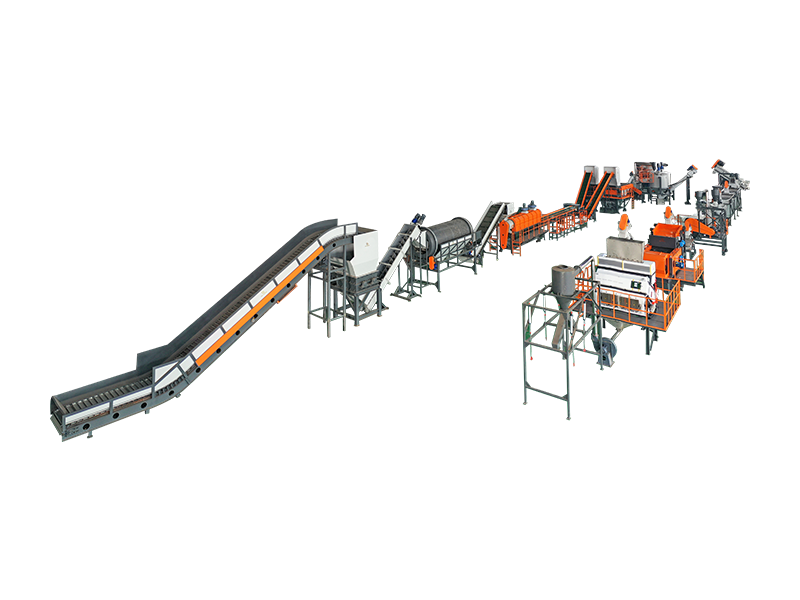

Next-generation PET bottle washing lines increasingly adopt automation technologies to reduce labor dependency and boost processing efficiency. Systems such as automated conveyors and centralized control panels have become standard. The entire production line is managed by PLCs and computer systems, enabling one-button start/stop and remote monitoring.

Leading manufacturers’ food-grade PET lines are also equipped with advanced material and color sorting machines (e.g., optical scanners powered by AI algorithms), capable of identifying and removing non-PET contaminants and colored flakes—greatly reducing the need for manual sorting.

Smart sensors enable real-time monitoring of flake impurity levels, moisture, color, etc., allowing timely adjustment of process parameters. Operational variables (temperature, flow rate, speed) are digitally managed, improving consistency and traceability.

Through automation and intelligent control, modern PET washing lines minimize human error and ensure consistent output quality.

ENG

ENG

English

English chinese

chinese