All technical specifications, configuration plans, and application recommendations were jointly developed by Boxin’s R&D and Project Departments, and finalized under the supervision of our Technical Director, [Mr. Liu]

PET Bottle Recycling Machine | Turnkey PET Bottle Washing & Pelletizing Recycling Line

From waste bottles to recycled pellets – a one-stop PET bottle recycling solution.

Whether you need a complete PET bottle recycling production line or equipment upgrade for a specific link, we can provide a one-stop solution for the entire chain from bottle → bottle flakes → recycled particles.

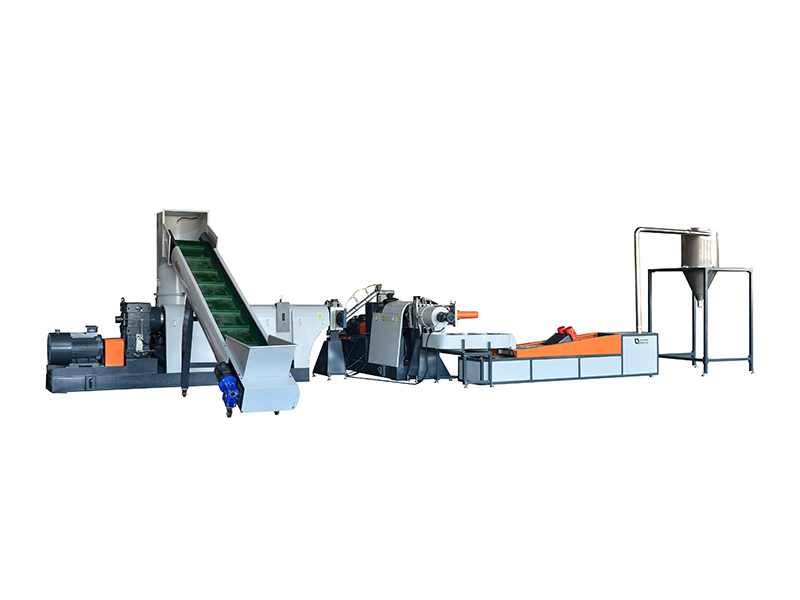

PET Bottle Washing LineEffectively removes labels, dirt, glue, and other contaminants from compressed bottle bales. Produces high-quality rPET flakes suitable for further processing. |

PET Pelletizing LineMelts and extrudes high-purity PET flakes into rPET pellets. Widely used in high-end applications such as preform injection molding and sheet extrusion. |

Plastic Bottle CrusherEfficiently crushes bottles into smaller pieces. Ideal for loose bottle recycling and entry-level recovery operations. |

OUR ADVANTAGES

As a specialized provider of complete solutions for plastic recycling—including washing, pelletizing, and crushing systems—we have:

|

|

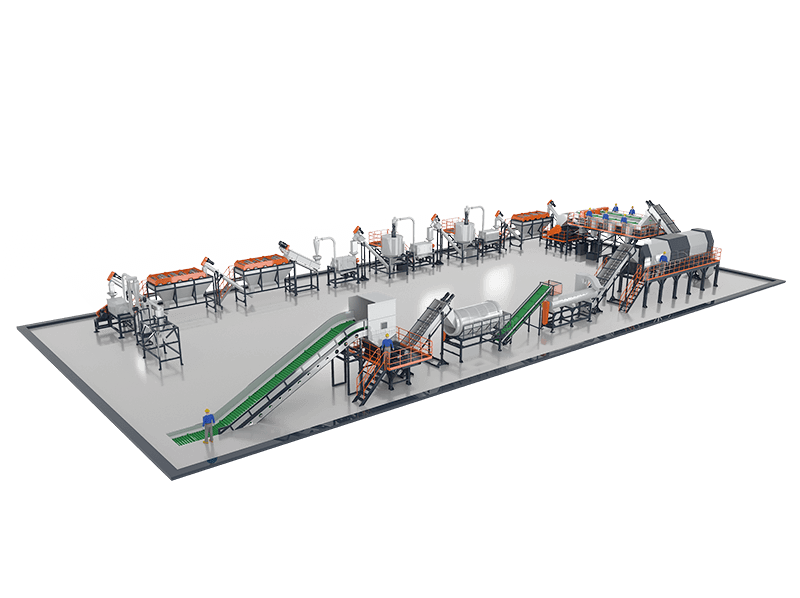

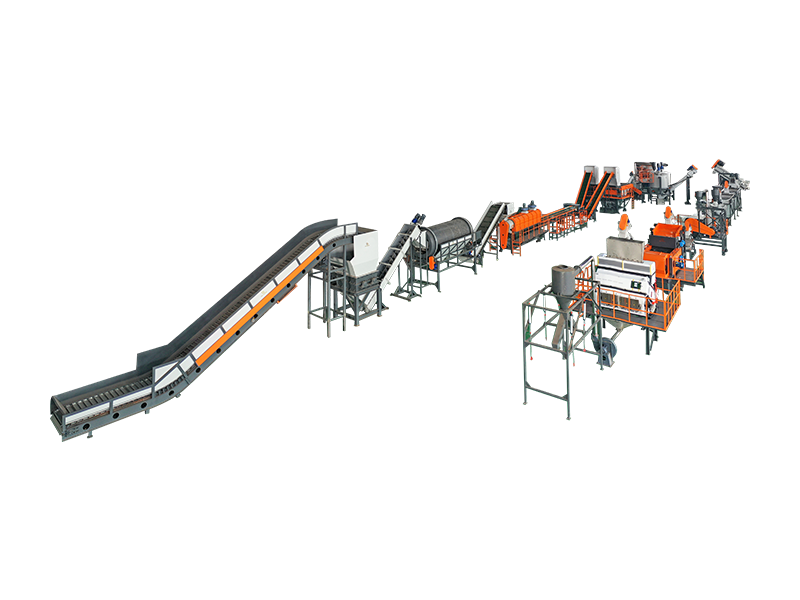

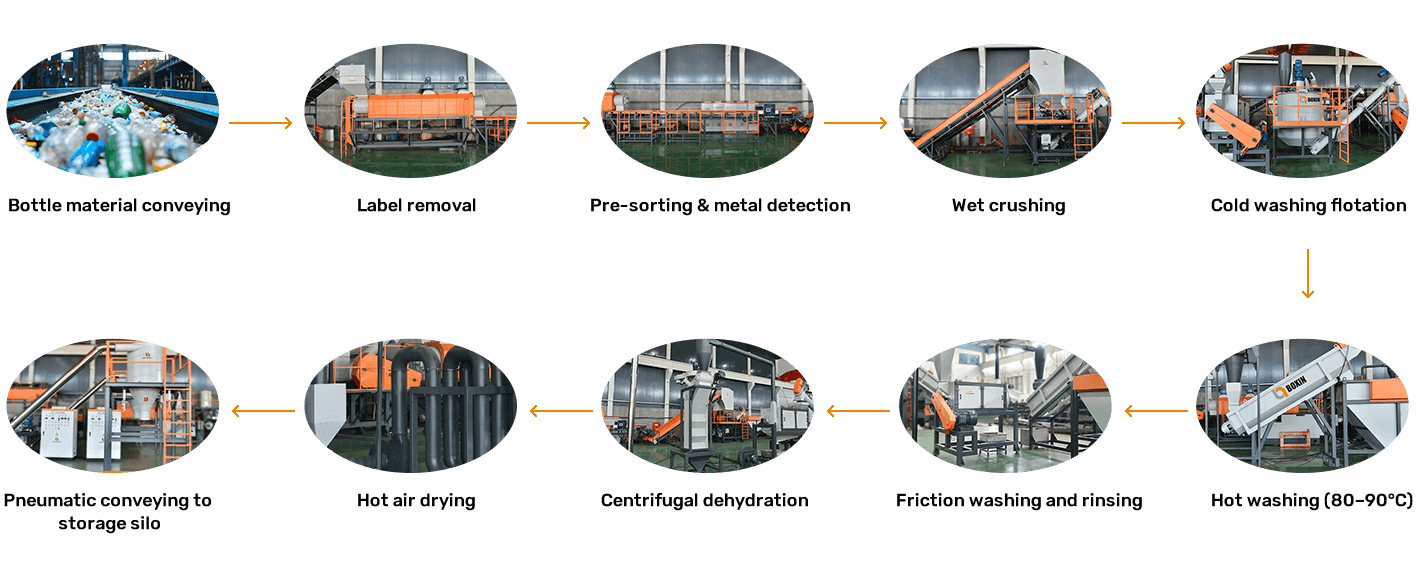

PET Bottle Washing Line Process

PET Bottle Recycling Washing Line Standard Configuration Overview

The PET washing line we designed includes 10+ key units, covering the entire process of bottle from "opening → crushing → washing → dehydration → filling".

The table below shows the module configuration of our standard PET washing line. If you have special bottle sources or production capacity requirements, we can also customize and expand it according to actual conditions.

|

Main modules |

Functional Description |

Features |

|---|---|---|

|

Unpacking pre-processing unit |

Break up the bottle bricks to ensure uniform feeding |

Unique dual-axis structure solves the problem of unpacking ultra-high pressure bottle bricks |

|

Screening unit |

Remove impurities such as stones, metals, sand, etc. |

Improve the stability of subsequent systems, especially suitable for imported bottle bricks |

|

Label removal unit |

Remove shrink film and other bottle labels |

Patented blade design, lower breakage rate and more thorough label removal |

|

Whole bottle pre-wash unit |

Initial cleaning of bottle surface dirt |

Improve the efficiency of subsequent bottle-flake cleaning |

|

Full bottle automatic sorting system |

Removes colored bottles, non-PET, metal, etc. |

Adopt optical system to improve output purity |

|

Manual sorting platform |

Manual secondary inspection to ensure quality |

Cooperate with metal detectors to control risk points throughout the process |

|

Crushing unit |

Crush the bottle body to 12mm standard bottle flakes |

High-efficiency shear angle design, blade life up to 800 tons |

|

Rinse and hot wash unit |

Remove bottle cap fragments, oil stains, glue, etc. |

Multi-stage hot wash system to improve cleanliness |

|

Rinse/friction wash unit |

Remove pharmaceutical residues and suspended impurities |

Neutralize pH value to ensure neutral treatment of bottle flakes |

|

Dehydration + drying unit |

Reduce the moisture content of bottle flakes |

Independent centrifugal dehydration + hot air drying, moisture content reduced to 1% |

|

Dust removal unit |

Remove residual dust on the surface of bottle flakes |

Z-type air separation + vibrating screen to ensure that the product is suitable for food grade applications |

|

Filling and storage unit |

Air conveying, quantitative weighing, packaging output |

Optional fully automatic weighing and packaging device |

Optional modules:

◎ Water treatment system: achieve >50% rinsing water recycling, reduce operating costs.

◎ Bottle flake optical sorting system: identification and rejection of aged bottles and bottles of different colors.

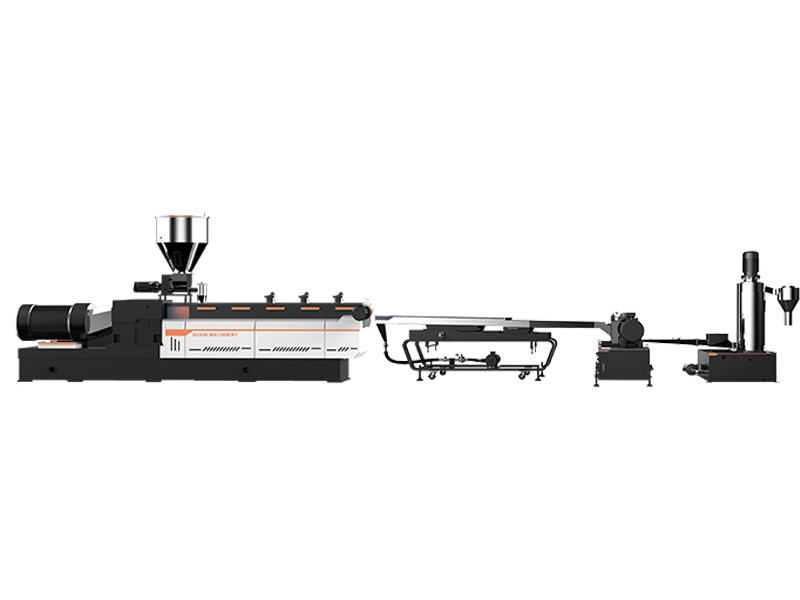

Standard Configuration Overview of PET Flake Pelletizing Line

If your washed PET flakes require further value-added processing, they can be upgraded into high-quality recycled PET pellets through our purpose-designed PET Melt Pelletizing Line.

The complete process includes:

Conveying → Crystallization & Drying → Melting & Filtration → Strand Pelletizing → Pneumatic Conveying & Packaging

This fully integrated system enables a true closed-loop recycling process, helping manufacturers turn post-consumer PET into high-grade raw materials for new applications.

| Module | Function Summary | Key Highlights |

|---|---|---|

| Crystallizing & Drying Unit | Pre-crystallizes and thoroughly dries PET flakes | Twin-tower dehumidifying system; final moisture content < 0.5% to prevent hydrolysis during melting |

| Melt Extrusion System | Melts flakes and removes impurities via filtration | Twin-screw extruder with dual-station screen changer; ensures stable throughput and high filtration precision |

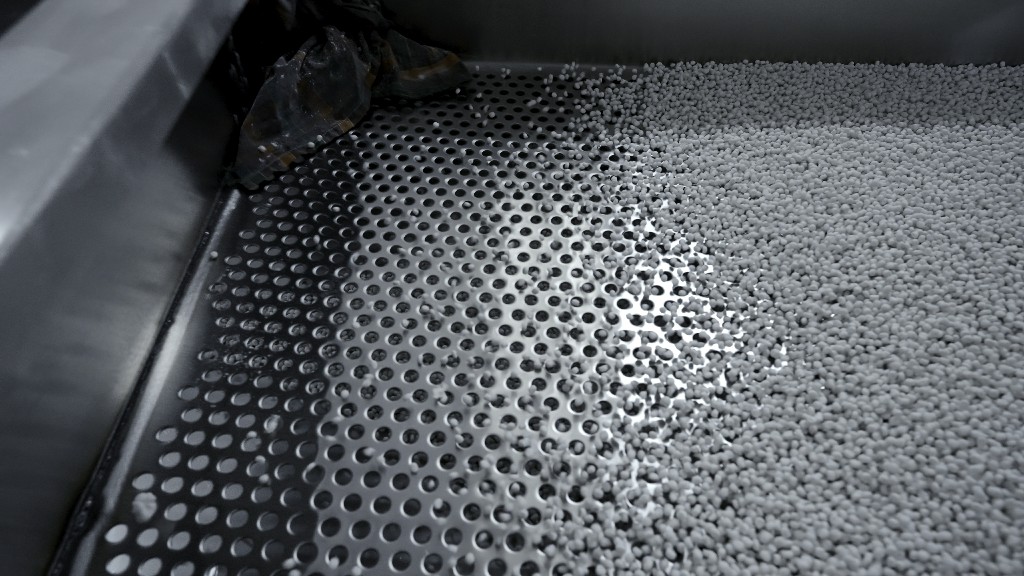

| Strand Pelletizing Unit | Cools and cuts the molten PET into pellets | Water cooling trough with air knife drying; produces uniform, burr-free pellets suitable for downstream processing |

| Cooling & Conveying System | Lowers the temperature of pellets and conveys them automatically | Integrated dedusting system ensures surface cleanliness meets export-grade requirements |

| Storage Silo & Packaging | Weighs, bags, and seals the finished pellets | Supports automatic batch packaging and real-time production monitoring for streamlined logistics |

Optional Upgrade Modules

| Module | Function |

|---|---|

| Solid-State Polycondensation (SSP) System | Enhances the Intrinsic Viscosity (IV) of flakes or pellets, enabling higher-end applications |

| Automated Intelligent Control System | Provides visualized monitoring and one-click adjustment of key processing parameters across modules |

| Melt Filtration System | Advanced impurity control to meet different quality standards of downstream products |

| Exhaust Gas Purification & Energy Recovery System | Purifies volatile gases generated during melting and recycles thermal energy for eco-friendly production |

Standalone Crushing System: Ideal for Injection & Blow Molding Scrap Recycling

Not all recycling starts with bottles.For injection molding and blow molding manufacturers, the real demand lies in the immediate recycling of production scrap—including sprues, rejects, and tail materials.

Our Standalone Crushing System is purpose-built for this scenario:

|

|

Recommended For:Injection molding factories · Blow molding factories · Food packaging plants · Centralized edge trim recyclers

PET Recycling Solutions for Different Applications

With over 20 years of expertise in integrated plastic recycling systems, we deeply understand the industry's demanding requirements for flake purity, throughput, and energy efficiency.

That's why we don’t just offer standard PET washing lines — we deliver modular and customizable systems tailored to your specific application needs, ensuring optimal performance and ROI.

| Application | Recommended Solution | Suggested Page |

|---|---|---|

| Food-Grade Flakes Production | Food-Grade PET Washing Line | Food-Grade PET Recycling Solution |

| Filament / POY-Grade Flakes | Filament-Grade PET Washing Line | PET Filament Recycling Solution |

| Chemical Fiber / Staple Fiber | Fiber-Grade PET Washing Line | PET Fiber Recycling Solution |

| Sheet / Film Production | PET Washing Line + Pelletizing Line | PET Sheet Production Solution |

| In-Factory Scrap Recycling (Injection/Blow Molding) | PET Crushing System | PET Crushing System Product Page |

| Bottle-to-Pellet Closed-Loop Recycling | Washing Line + High-Efficiency Pelletizing Line | PET Pelletizing Line Product Page |

Article directories

News categories

Choose Material

Related Machines

ENG

ENG

English

English chinese

chinese