Applications and Quality Standards of Recycled Flakes

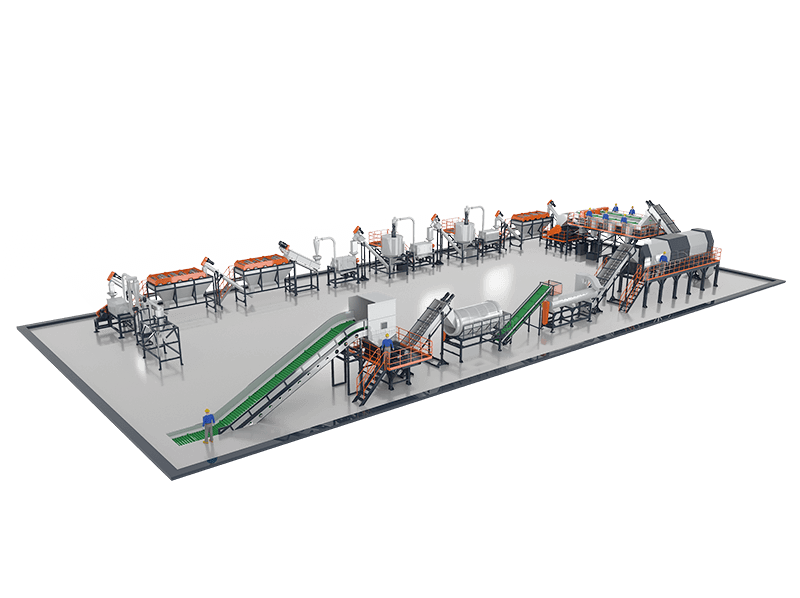

The cleaned and dried recycled flakes and re-pelletized granules can be used in a variety of applications:

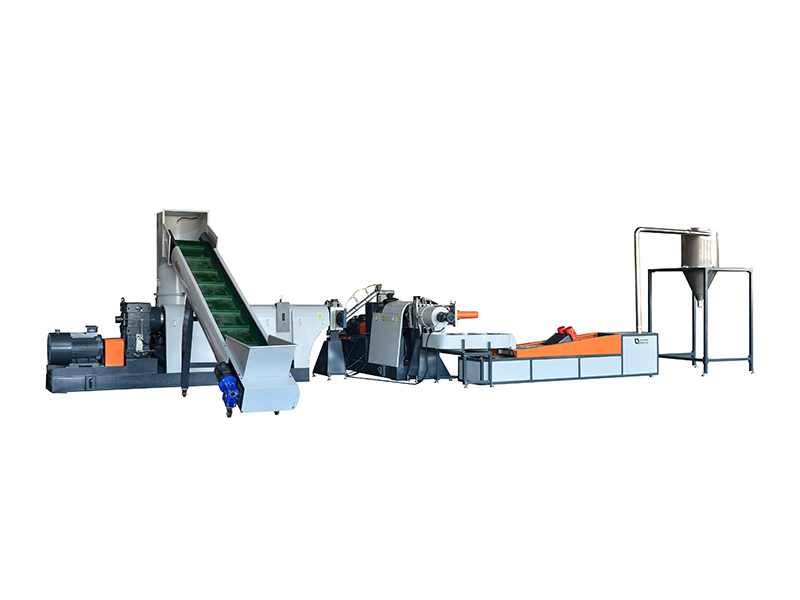

1. Woven Bag Recycling

After pelletizing or hot-cut filament drawing, the recycled PP can be used to produce fiber-grade PP material for new woven bags or non-woven fabrics.

Purity requirement: Relatively lower, but all colored contaminants, paper scraps, and visible impurities must be removed.Moisture content: Must be controlled below 1% to ensure stable processing.

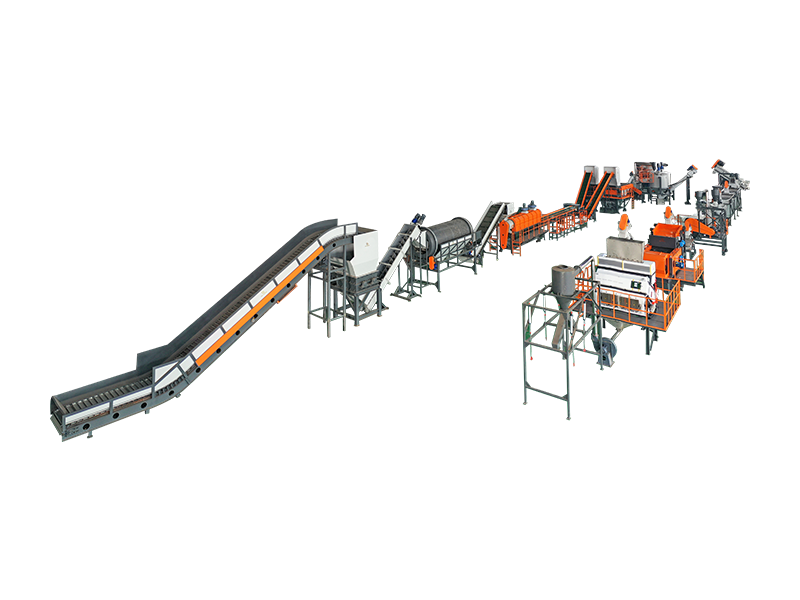

2. Injection Molding Products

The recycled pellets can be used for injection molding applications such as furniture parts, containers, and automotive components.

Material requirement: Stable material strength and melt flow index (MFI).Quality control: Stricter moisture and impurity standards are required. Residual contaminants or moisture can cause bubbles and performance degradation during melting.Recommended: Final product moisture content should be less than 0.5%, and melt filtration should be applied to ensure product quality.

3. Blow Molding / Extrusion Pellets

The recycled PP pellets can also be used for blow molding containers or film extrusion.

Product grade: Typically classified as blow molding grade.Requirements: High tolerance for color, but the pellets must be odorless and low in contamination. Both injection and blow molding grades require extremely low moisture to avoid defective products.

4. Other Downstream Applications

Recycled materials can also be used for pipe production, household appliance shells, and daily-use items. Proper formulation adjustments can be made according to melt flow index (MFI) and impact strength requirements for each specific application.

5. Cleanliness Standards

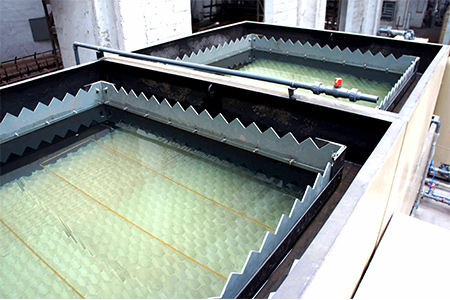

Recycled flakes must not contain visible organic contamination (such as oil stains or clay clumps) or harmful foreign substances.

EN

EN

English

English 简体中文

简体中文 Русский

Русский España

España عرب .

عرب .