Choose Material

Related Machines

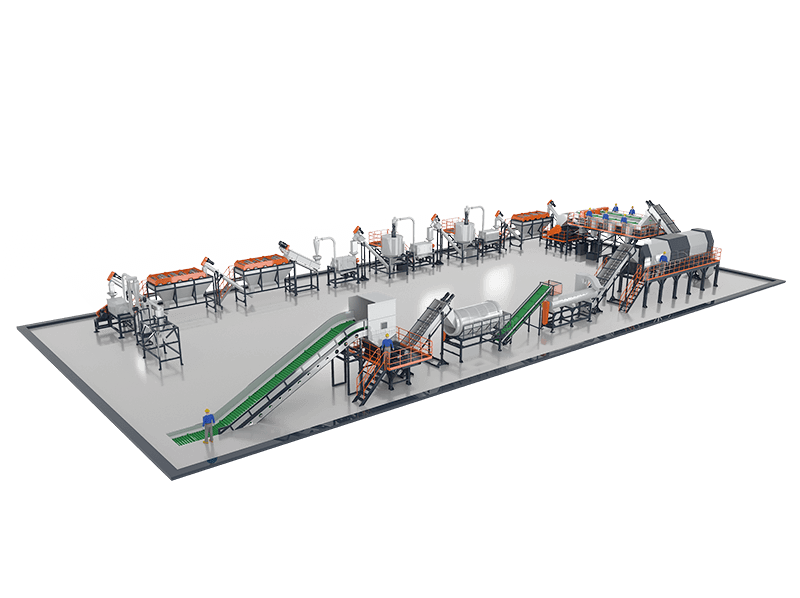

Plastic Film Recycling Washing Line

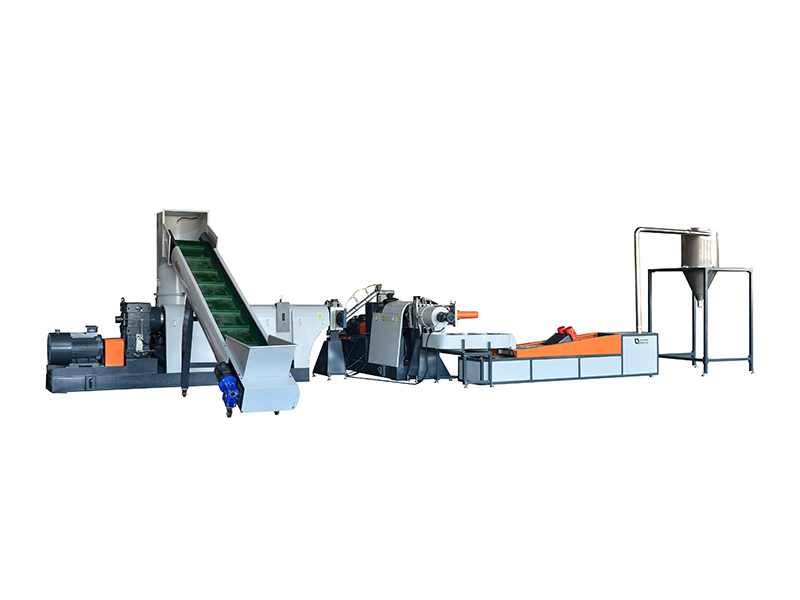

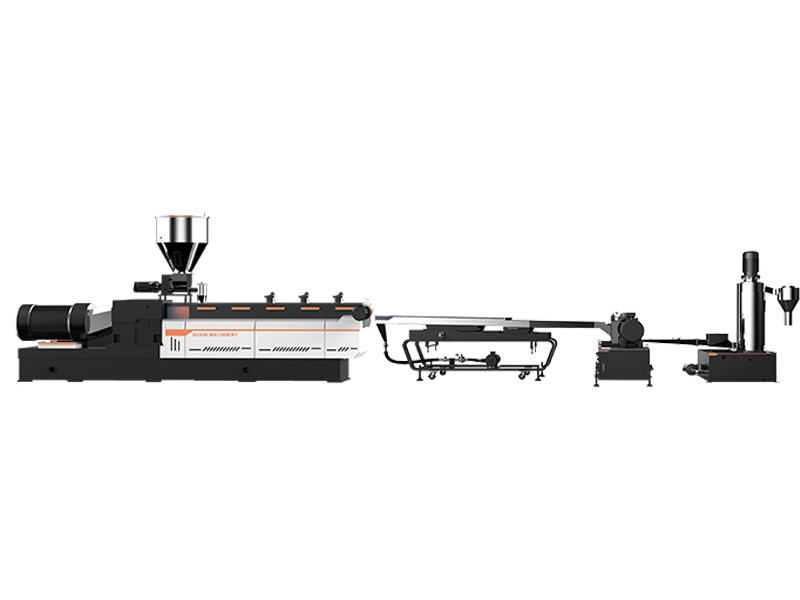

PE Film Pelletizing Machine

Heavy-Duty waste plastic crusher machine

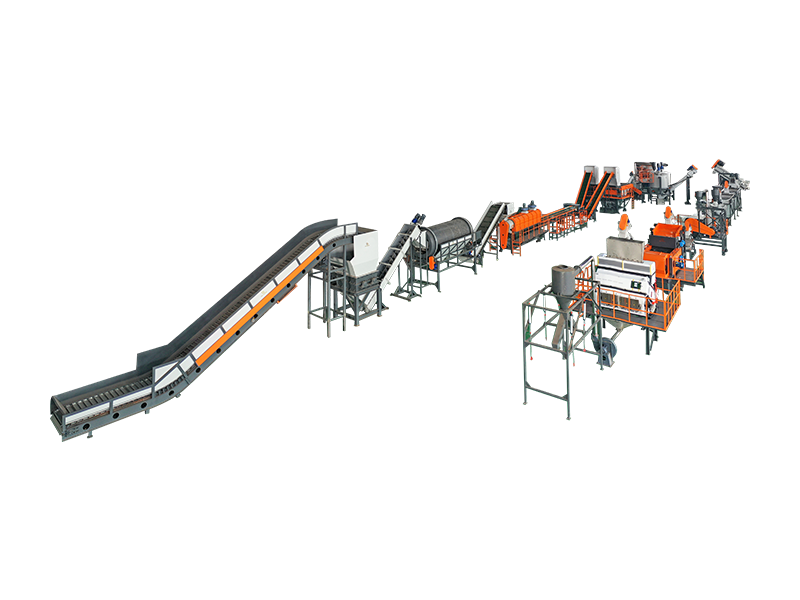

PET Bottle Washing Line

PP Woven Bag Washing Line

HDPE Washing Line

Bottle-to-Bottle Recycling (Food-Grade PET Bottle Washing Line)

Fiber Grade PET Bottle Washing Line

EN

EN

English

English 简体中文

简体中文 Русский

Русский España

España عرب .

عرب .