Milk Bottle Recycling Machine: The Strategic Key to PCR Compliance & High-Value HDPE Recovery

|

Although HDPE milk bottles appear structurally simple, the contaminants they carry possess distinct biochemical properties. This often causes general-purpose waste plastic washing equipment to fall short when processing this type of raw material. |

Biological Fermentation and Odor Mechanisms

Unlike PET beverage bottles, which primarily retain sugar and water residues, HDPE milk bottles retain fats and proteins.

Lactic Acid Fermentation: Lactic acid bacteria present in the residual milk convert lactose into lactic acid. This significantly lowers the pH value of the system.

Lipolysis: Even more critical is the hydrolysis of fats. Triglycerides in the milk break down into free fatty acids under enzymatic action, specifically Butyric Acid. Butyric acid possesses a strong, repulsive rancid odor (similar to vomit) and is extremely difficult to remove through simple water washing.

Protein Adsorption: Casein, the primary protein in milk, exhibits strong adhesive properties. Once dried, it adheres firmly to the HDPE bottle walls like glue.

Deep Insight: If the washing line fails to thoroughly remove these organic residues, the high temperatures (>200°C) during the subsequent Pelletizing process will cause residual proteins to carbonize (turning into black spots) and fatty acids to volatilize (forming bubbles), while releasing a pungent burnt odor. Such malodorous recycled granules will be directly rejected by the high-end market. Therefore, Deodorization is not merely about improving the working environment; it is the baseline requirement for product qualification.

Physical Impurity Complexities: Bottle Caps and Labels

In addition to biological residues, physical components constitute a significant challenge:

-

PP Cap Contamination: While the milk bottle body is HDPE, the caps and security rings are typically made of Polypropylene (PP). Although both are polyolefins with a density of less than 1 (meaning both float on water), their melting points differ significantly (HDPE is approx. 130°C, while PP is approx. 165°C). The mixing of excessive PP into HDPE will degrade the physical properties of the final product (such as reducing impact strength).

-

Labels and Glue: Traditional paper labels are increasingly being replaced by self-adhesive labels. If these adhesives are not thoroughly removed, they will clog the extruder's screen changer and cause "pockmarks" or surface defects on the recycled pellets.

-

Multi-layer Composite Bottles: Some long-life milk (UHT) packaging may contain barrier layers (such as EVOH), which are treated as impurities during the recycling process.

Process Overview: Boxin Machinery's System-Level Solution

|

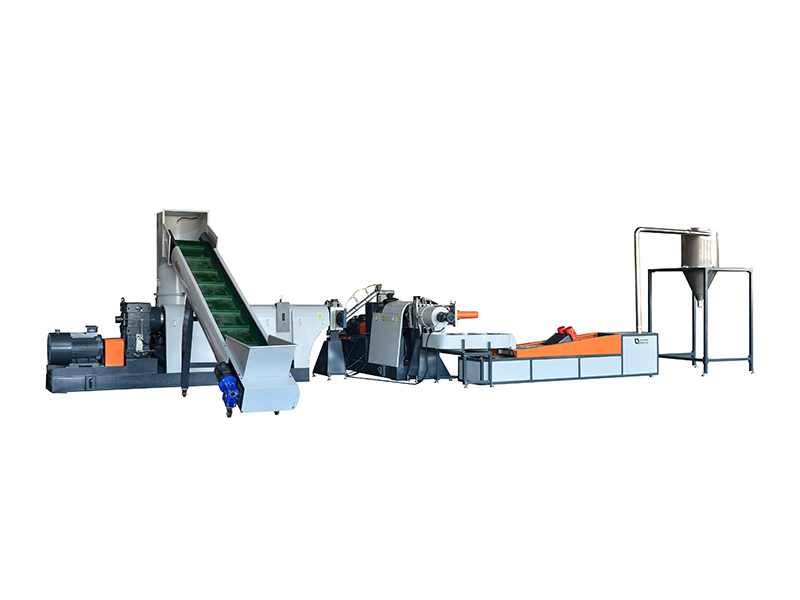

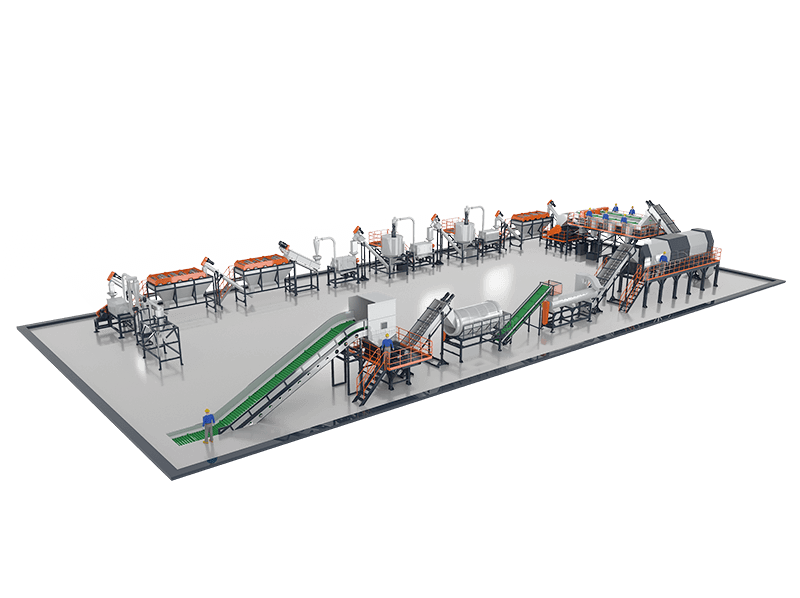

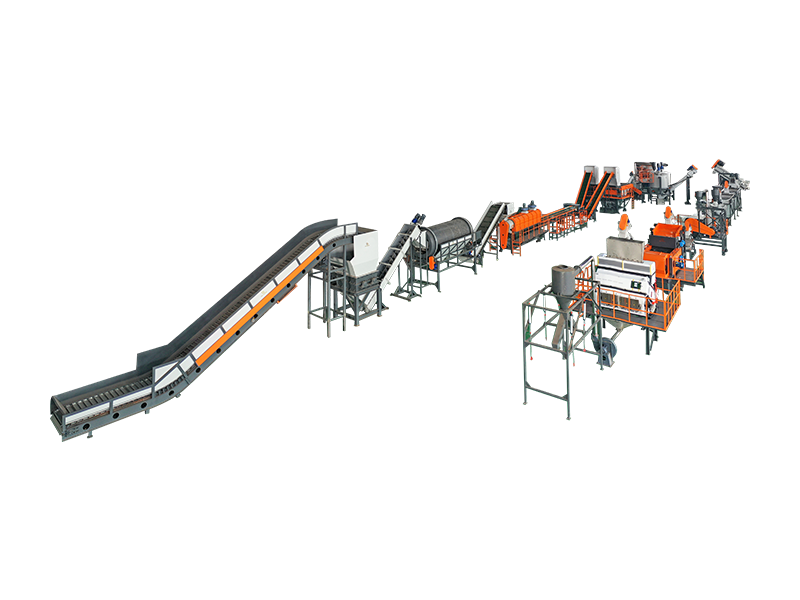

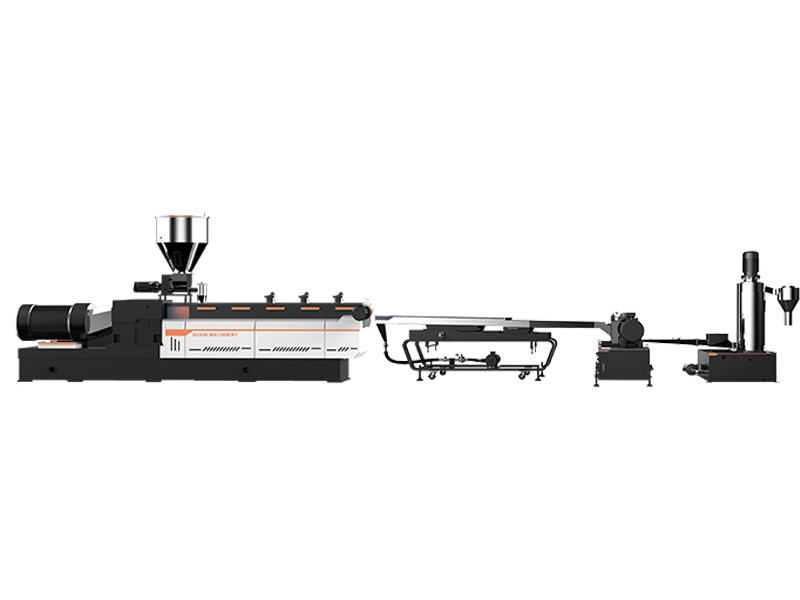

Addressing the pain points mentioned above, professional plastic recycling equipment manufacturer, Boxin Machinery, has developed a specialized HDPE Milk Bottle Recycling Washing Line. This is not merely a single machine, but a recycling system integrating mechanical crushing, chemical washing, physical separation, and optical sorting. |

A standard high-throughput (e.g., 1000kg/h - 3000kg/h) washing line typically comprises the following core modules:

-

Size Reduction Module: Wet crushing to control particle size.

-

Hot Washing Module: The core process for oil removal and deodorization.

-

Fine Washing Module: Friction washing.

-

Separation Module: Sink-float separation, air classification, and optical sorting.

-

Drying: Dewatering and thermal pipe drying.

Stage 1: Wet Crushing – Particle Size Control and Preliminary Cleaning

Crushing is the physical core of the recycling line. For HDPE milk bottles, Wet Crushing is the industry standard configuration.

Engineering Advantages of Wet Crushing

Unlike dry crushing, a wet crusher continuously injects water into the cutting chamber during operation.

-

Cooling and Temperature Reduction: HDPE has a relatively low softening point. High-speed rotating blades generate significant frictional heat. Without cooling, the plastic will melt and block the screen (Smearing). Water circulation carries away heat, ensuring continuous operation.

-

Cleaning Efficiency: The specific surface area of the material is greatest at the moment of crushing. The powerful turbulence of the water immediately flushes away label pulp and trapped dirt, acting as a "first stage fine washing."

-

Extended Tool Life: Water acts as a lubricant, reducing friction and wear between the blades and the material. Boxin Machinery selects D2 high wear-resistant alloy steel for our knives and designs specific shear angles (V-shape or Claw-type) to adapt to the crushing of hollow containers.

Screen Size: The crusher screen aperture is typically set between 12mm - 16mm. This size is the balance point between washing efficiency and throughput: too small increases fines loss; too large leads to incomplete washing and difficulty in fully detaching labels.

Stage 2: High-Temperature Hot Washing – Deodorization and Degreasing

Thermodynamics and Kinetics of Chemical Cleaning

To thoroughly remove fats and proteins from milk bottles, cold water washing is ineffective. A high-temperature, alkaline chemical reaction environment must be established.

-

Saponification: Sodium Hydroxide (NaOH/Caustic Soda) is added to the hot wash tank. At high temperatures, NaOH reacts with milk fats (triglycerides) in a saponification reaction, producing glycerol and sodium fatty acids (soap). Both products are water-soluble, stripping insoluble grease from the plastic surface.

-

Protein Denaturation and Dissolution: An alkaline environment helps hydrolyze proteins, causing them to loosen and detach.

-

Glue Removal: High-temperature lye also softens and dissolves acrylate adhesives remaining from labels.

Recommended Process Parameters for HDPE Milk Bottle Hot Washing

| Parameter | Recommended Range | Scientific Basis / Engineering Significance |

| Temperature | 85°C - 95°C | Above the melting point of milk fat to accelerate chemical reactions, but must be below the HDPE softening point to prevent clumping. |

| Alkaline Concentration | 1.0% - 3.0% (NaOH) | Too low fails to remove oil; too high increases costs and makes rinsing difficult. Must be dynamically adjusted based on contamination levels. |

| Additives | Surfactant | Lowers surface tension of water, allowing lye to penetrate deep into micro-cracks and scratches to clean out bacteria. |

| Dwell Time | 10 - 20 Minutes | Ensures sufficient kinetic conditions for the chemical reactions to fully complete. |

| Mechanical Agitation | Low-speed, High-torque Paddles | Keeps material in suspension, provides necessary mechanical friction to scrub off softened dirt, and prevents sedimentation. |

Due to the involvement of high-temperature lye, Boxin Machinery's hot washing tanks and related piping are all made of SUS304 stainless steel to prevent corrosion. To maintain the high temperature of 90°C, steam heating coils or thermal oil heating systems are typically equipped. Considering energy costs, advanced lines are designed with insulation layers and chemical liquid recirculation systems.

Stage 3: Fine Washing

The material exiting the hot wash is a "soup" mixed with plastic flakes, lye water, paper pulp, and dissolved oils. The next task is to separate the clean plastic.

High-Speed Friction Washer

The material from the hot wash first enters the friction washer.

-

Working Principle: The main shaft speed is typically above 1200 RPM. Paddles strike the material, generating immense centrifugal force and self-friction between materials.

-

Functions:

-

Dewatering Dirty Water: Forcibly spins dirty lye water and oil sludge out through the screen.

-

Surface Stripping: Further strips away stubborn label residues.

-

Pre-rinsing Preparation: Prepares the material for the fresh water rinsing tank, reducing contaminants carried over to the next process.

-

Stage 4: Separation and Impurity Removal

Sink-Float Separation Tank

This is the key step for impurity separation using density differences.

-

HDPE/PP (Floating Material): Density approx. 0.91-0.96 g/cm³, less than water, floats on the surface. Pushed to the discharge outlet by paddle wheels.

-

Heavy Impurities (Sinking Material): PET, PVC, PS, ABS, rubber, metal, sand, etc., have densities greater than 1. They sink to the bottom and are removed by a bottom discharge screw.

-

Cleaning Action: Sink-float tanks are typically long (e.g., 4m - 6m). Through multiple baffles and overflow designs, they also serve to rinse off residual lye.

Technical Pain Point: Separation of PP and HDPE

At this step, both PP caps and HDPE bottle flakes float, making water density separation impossible. The mainstream method is to perform color/material sorting at the flake stage, and use a Zig-Zag air separator (label remover) to remove fine labels and dust.

Optical Sorting: The Core Value-Added Step

This is the core process that turns "ordinary material" into "premium material." As mentioned earlier, there is a huge price difference between natural color material and mixed color material. The dried mixed flakes (containing white HDPE and red/blue/green PP caps) enter the Optical Color Sorter.

-

Technology Principles:

-

Visible Light Camera (CCD): Identifies color. Rejects red, blue, yellow, and other colored cap fragments from the white HDPE stream.

-

Near Infrared (NIR) Spectroscopy: Identifies material. Rejects transparent PET flakes that may have mixed in, or PP flakes (if material purification is required).

-

Ejectors: Upon identifying a target impurity, high-frequency air guns instantly blast air to blow the impurity into the waste channel.

-

-

Sorting Effect: After one or two passes of color and material sorting, the purity of natural HDPE flakes can reach 98% - 99%, free of colored caps.

Stage 5: Drying

-

Centrifugal Dryer: Similar to a spin cycle in a washing machine, it uses centrifugal force to remove surface water. Moisture content is typically reduced to around 5%.

-

Hot Air Pipe Dryer: Uses hot air to mix with and transport the material through long pipes, flash-evaporating residual moisture.

-

Target Moisture Content: The final flake moisture content must be controlled to below 1% - 3%.

Conclusion and Recommendations

HDPE milk bottle recycling is a precision science that transforms waste into resources. Facing the widening price differential between natural (clear) and mixed-color materials, and the urgent demand from brand owners for odorless PCR (Post-Consumer Recycled) materials, the traditional model of simple crushing and washing is no longer sustainable.

Core Conclusions:

-

High-Temperature Hot Washing is the Only Pathway for Deodorization: It is essential to guarantee a high-temperature alkaline washing duration at over 85°C to thoroughly eliminate fatty acid and protein residues.

-

Color Sorting Determines Profitability: Integrating high-precision optical sorting systems to separate multicolored PP caps from natural HDPE is the key to securing a significant market premium.

-

Specialized Equipment Selection is Crucial: Choosing an equipment manufacturer like Boxin Machinery, which provides designs optimized for thick-walled rigid plastics, can significantly reduce long-term operational costs and enhance product quality.

For enterprises intending to enter this sector, it is recommended to prioritize evaluating the equipment manufacturer's capabilities in hot wash chemical process control and full-line automation integration. These will be the decisive factors for success in future market competition.

Article directories

News categories

Choose Material

Related Machines

Plastic Film Recycling Washing Line

PE Film Pelletizing Machine

Heavy-Duty waste plastic crusher machine

PET Bottle Washing Line

PP Woven Bag Washing Line

HDPE Washing Line

Bottle-to-Bottle Recycling (Food-Grade PET Bottle Washing Line)

Fiber Grade PET Bottle Washing Line

EN

EN

English

English 简体中文

简体中文 Русский

Русский España

España عرب .

عرب .