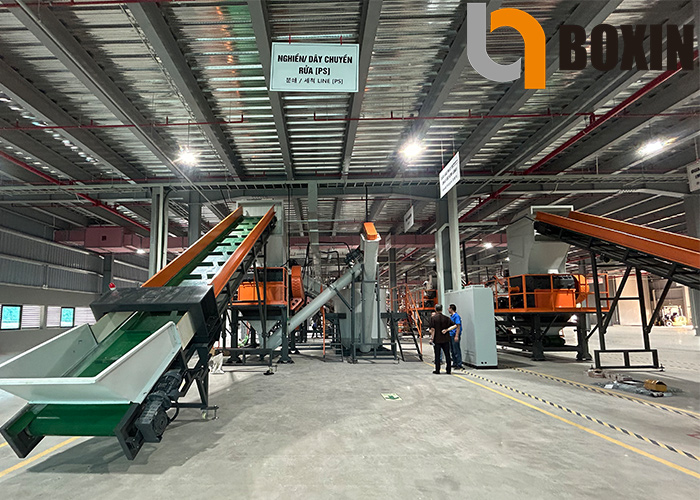

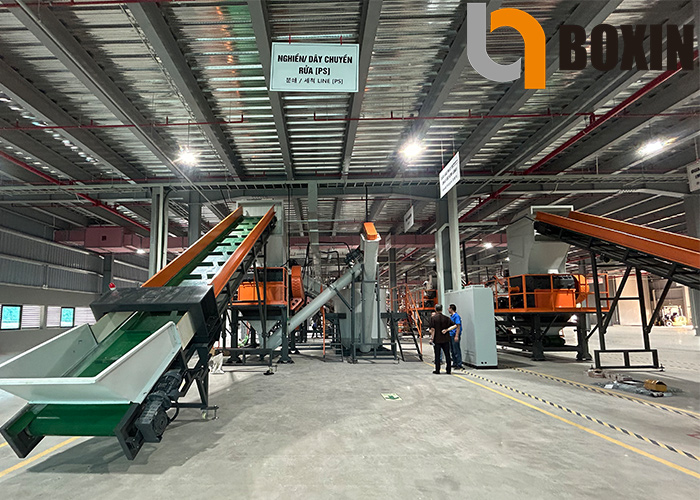

This Vietnam facility utilizes a specialized dual-line system to process electronic waste. Boxin provided two independent washing lines to recycle PS IC Trays and PET IC Trays separately, preventing material cross-contamination.

Challenge: Material Separation

The client collects mixed electronic packaging waste (IC Trays). The biggest challenge is that both PS (Polystyrene) and PET (Polyethylene Terephthalate) are heavier than water (sinkers).

- Density Issue: Since both materials sink, they cannot be separated by water density in a float-sink tank.

- Cross-Contamination: Mixing PS and PET flakes would ruin the downstream pelletizing process due to different melting points.

- Label Residue: IC trays often have sticky barcodes that require intense friction to remove.

The Solution: Parallel Lines

To solve the separation issue, Boxin deployed two dedicated lines. This allows the client to process PS trays on Line A and PET trays on Line B simultaneously or in batches.

Process Detail: Sticker Removal

Electronic trays typically come with adhesive labels. Both lines are equipped with Boxin's high-speed friction washers running at 1200 RPM. The intense friction effectively scrubs off paper labels and glue residue, ensuring the final PS and PET flakes are clean and ready for high-quality granulation.

Transformation Result

Converting e-waste into high-value recycled resin.

Input: Mixed IC Trays

Input: Mixed IC Trays Output: Pure PS / PET Flakes

Output: Pure PS / PET FlakesSite Gallery

Start Your Electronic Waste Recycling Project

Specialized solutions for hard plastics: PS, PET, ABS, and PC.

See Boxin's Hard Plastic Washing Solution

Includes ROI Analysis & Spare Parts Kit

EN

EN

English

English 简体中文

简体中文 Русский

Русский España

España عرب .

عرب .