plastic recycling granulating line – a system designed to transform plastic waste into reusable pellets.

These pellets can then serve as raw material for new plastic products, reducing the need for virgin plastics and supporting a circular economy

What Is a Plastic Recycling Granulating Line?

A plastic recycling granulating line (also known as a plastic pelletizing line) is a complete processing system that converts waste plastics or raw polymer materials into standardized plastic granules (pellets).

In practical terms, it takes in discarded or scrap plastic—such as used packaging films, bottles, or production off-cuts—and processes them through melting and cutting to form uniform pellets. These pellets are easier to handle, transport, and reuse in manufacturing processes like injection molding, extrusion, or textile fiber production

Types of Plastic Recycling Granulating Lines

Not all granulating lines are the same. Manufacturers design different types of plastic recycling granulating lines to handle specific materials, output levels, and end-product requirements. Here are some common ways to categorize these systems:

By Application (Recycling vs. Compounding):

Recycling Granulation Lines are optimized for converting waste plastics (like used packaging, films, bottles) into basic pellets that can replace virgin resin. They focus on handling contaminants and variability in scrap plastic. On the other hand,

Compounding Granulation Lines are used to blend plastics with additives or fillers (like color masterbatch, fiberglass, or flame retardants) to produce specialty plastic compounds. Compounding lines often use twin-screw extruders to achieve thorough mixing of additives into the polymer melt, resulting in pellets with specific engineered properties.

By Pelletizing Method:

Strand Pelletizing Lines: Suited for many rigid or solid plastics. The extrudate comes out as strands that are cooled and cut. This method is relatively simple and common for materials like PET.

Water-Ring Pelletizing Lines: Often used for soft, low-melt viscosity plastics such as LDPE or LLDPE (film scrap). The die face cutter with water cooling prevents the soft melt from sticking and yields uniform pellets.

Underwater Pelletizing Lines: These are high-end systems where the cutting occurs in a water chamber right at the die. They are ideal for high-throughput production and for certain engineering plastics or temperature-sensitive materials. Underwater systems provide very consistent pellets and can handle large output capacities, but are more complex.

By Input Material Type:

Rigid Plastic Lines: For hard plastics like chunks of HDPE, PP (think bottle caps, crates, thick containers), the line may include robust shredders or granulators to pre-cut materials, and sometimes multiple filtration stages to handle contaminants.

Film and Soft Plastic Lines: Thin films (LDPE, LLDPE film scraps, PP woven bags) are voluminous and lightweight, so these lines often incorporate a compactor or agglomerator at the feeder. The compactor pre-heats and densifies film into lumps that can be fed steadily into the extruder. This prevents films from fluffing and improves throughput.

Foam Plastics Lines: Materials like EPS (Styrofoam) or EPE foam need densifiers (which apply heat and pressure to collapse the foam) before extrusion. Otherwise, their low bulk density makes direct feeding inefficient.

PET Bottle Flake Lines: PET has its own nuances (it’s hygroscopic, meaning it readily absorbs moisture). Lines for PET often include drying systems or vacuum degassing to remove moisture and might use twin-screw extruders with venting to ensure high-quality pellets that can even be used for food-grade applications.

By Scale and Output Capacity:

Small-Scale Lines: Suitable for startups or small recycling operations, maybe 100–200 kg/hour output. These are usually simpler and lower in cost, yet still capable of producing quality pellets.

Medium Capacity Lines: Mid-range industrial systems (300–800 kg/hour, for example) used by many recycling companies. They balance efficiency and cost, and often include moderate automation.

High-Capacity Lines: Large-scale production lines (900 kg/hour and up) used in major recycling facilities or resin production plants. They often feature high-torque extruders, advanced pelletizers, and full automation to run continuously at large throughput. High-capacity lines are designed for enterprises handling huge volumes of plastic waste and require robust design to operate non-stop.

Each type of plastic granulating line is designed with specific use cases in mind. For instance, a double-stage plastic recycling line (two extruders in series) might be chosen for heavily printed or highly contaminated plastics – the first stage focuses on melting and filtering out impurities, and the second stage ensures a fine melt filtration and stable extrusion to yield top-quality pellets. On the other hand, a simple single-stage line could suffice for clean factory scrap. Understanding the differences allows businesses to pick a solution that best fits their material and production needs.

Key Components of a Plastic Granulation Line

To understand how these systems work, let's break down the key components typically found in a plastic pelletizing/granulating line:

1. Feeding System: This is the start of the line, where prepared plastic material is loaded. It can be as simple as a hopper for manual feeding or as automated as conveyor belts, loaders, or compactors that consistently feed plastic scrap into the extruder. The feeding method may vary depending on the material form (e.g., flakes, films, or regrind pieces).

2. Extrusion Unit (Melting & Homogenization): The extruder is the heart of the granulating line. It usually consists of a long barrel with either a single screw or twin screws that rotate to convey and melt the plastic. As plastics travel through the heated barrel, they melt into a viscous fluid. Single-screw extruders are common for straightforward recycling of a single material, while twin-screw extruders are preferred for compounding or handling mixed materials due to better mixing capability and higher output. This stage ensures the plastic is thoroughly melted and homogenized – achieving uniform temperature and consistency.

3.Degassing/Venting System: Many plastics contain moisture or trapped gases (especially if the material wasn’t perfectly dry or has inks/contaminants). The extruder often has a degassing section (vent ports) to evacuate steam and volatile gases from the molten plastic. Removing moisture is crucial to avoid defects (like holes or brittleness) in the final pellets.

4. Filtration System (Screen Changer): Before the molten plastic is formed into pellets, it passes through a fine mesh screen or melt filter. This step captures any remaining contaminants or unmelted particles, ensuring the output is high-quality plastic with no debris. Modern lines use continuous or automatic screen changers so that filtration doesn’t interrupt production.

5. Pelletizing System (Cutting Unit): Once filtered, the clean molten plastic is forced out through a die head. The die has many small holes, from which strands of molten plastic exit. These strands are immediately cut into small granules by a rotating blade system as they emerge, forming pellets. Depending on the design, the cutting can occur in different ways:

- Strand Pelletizing: The molten polymer comes out as spaghetti-like strands that are cooled (by water) and then cut into pellets by a cutter after solidification.

- Water-Ring Pelletizing: The cut is done at the die face with a ring of water flowing, which cools and carries the pellets away – often used for softer plastics like PE film.

- Underwater Pelletizing: The cutting happens underwater right at the die face, ideal for high-throughput lines and certain polymers, instantly cooling pellets as they are cut.

6. Cooling System: Right after cutting, pellets are hot and need cooling to solidify and prevent clumping. Depending on the system, pellets are cooled by water or air. For example, in strand pelletizing, pellets may go through a water bath or cooling conveyor, whereas underwater pelletizing already uses water to cool in the cutting chamber.

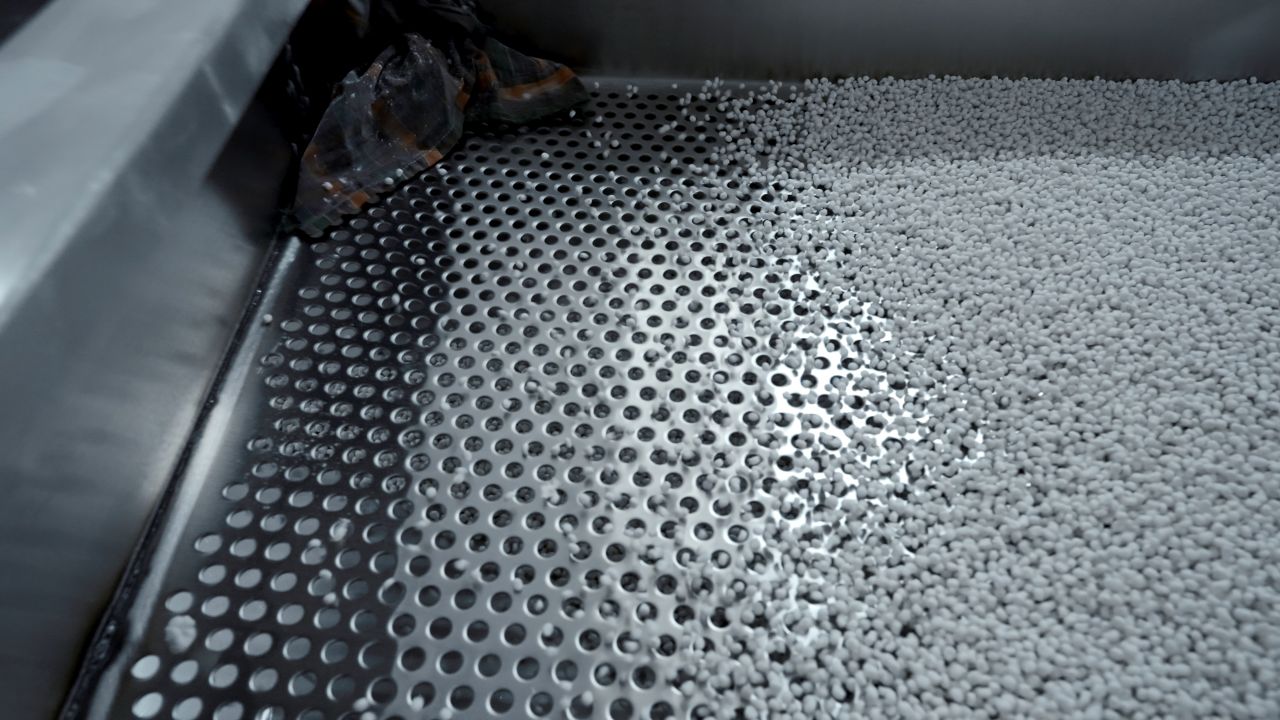

7. Vibrating Sieve / Classifier: High-quality granulating lines include a screening step where pellets pass over a vibratory sieve or screen. This removes any fine particles (dust or “fines”) and separates out any oversized pellets, ensuring a uniform pellet size for the final product. Consistent pellet size is important for reliable performance in molding machines downstream.

8. Storage and Packaging: Finally, the dried pellets are conveyed to storage silos or collection bins. They may be packed in bags or big containers. At this stage, the recycled plastic pellets are ready to be reused in manufacturing.

Each of these components works in sequence to turn plastic waste into high-quality granules. Some recycling lines also integrate pre-processing equipment like shredders or crushers (upstream of the feeding system) especially if the input material is large or in baled form. In fact, a full plastic recycling granulating production line often includes crushing, washing, and drying equipment before extrusion if dealing with dirty post-consumer waste. For instance, a line might start with a crusher to chop bottles into flakes, wash and dry them, then feed into the pelletizing extruder. The exact configuration is customizable based on the material and cleanliness required.

Uses and Applications of Plastic Recycling Granulating Lines

Plastic Manufacturers and Molders: Many plastic product manufacturers use pelletizing lines in-house to recycle their own production waste. For example, an injection molding factory might reprocess sprues, defective parts, or trimmings by pelletizing them and then blending the recycled pellets back into new production. This reduces material costs and waste.

Recycling Companies: Specialized recycling facilities collect post-consumer plastic waste (like bottles, bags, packaging films) and use granulating lines to convert this waste into resin pellets that can be sold to manufacturers. The recycled pellets become feedstock for a variety of products – from new bottles and containers to plastic lumber, pipes, and textile fibers. Reusable granules from waste plastics significantly reduce demand for virgin resin and minimize environmental impact, making these lines vital for sustainability goals.

Compounding and Material Development: In compounding facilities, granulating lines mix recycled plastics with additives to create materials with specific properties. For instance, adding wood fiber to recycled PP to make composite pellets for furniture, or adding color and UV stabilizers to recycled PE for outdoor products. These compounded pellets serve niche industries (automotive parts, construction materials, etc.) with customized recycled plastics.

Advantages of Boxin‘s Plastic Granulating Lines

Efficient Recycling & Cost Savings: A good granulating line converts waste plastic into valuable raw material with high efficiency. This helps manufacturers reduce reliance on expensive virgin polymers and cuts down raw material costs. Reprocessing in-house scrap or locally collected waste can substantially lower expenses while also reducing environmental impact (less plastic sent to landfills or incinerators).

High Output and Uniform Pellet Quality: Advanced lines are designed for high throughput (output), meaning you can process a large volume of plastic per hour. Despite the high production rate, they maintain consistent pellet size and shape, which ensures the re-pelletized material performs well in downstream processes. Uniform, high-quality pellets translate to reliable manufacturing of new products without jams or quality issues.

Energy Savings and Low Operating Costs: Modern plastic pelletizing machines emphasize energy efficiency – they maximize output for every kilowatt of energy consumed. Better barrel heating technology, optimized motor and gearbox designs, and intelligent process controls all help lower the energy per kg of plastic processed. Lower energy consumption not only reduces electricity bills but also the carbon footprint of the recycling operation. Additionally, efficient designs can reduce wear and wastage, further lowering operating costs over time.

User-Friendly Operation with Intelligent Control: Today’s granulation lines often come with advanced automation and control systems. PLC (Programmable Logic Controller) touch-screen interfaces allow operators to easily monitor temperatures, motor loads, and throughput rates. Automated feedback systems can adjust feeding speed or extruder parameters to maintain stable output. Some lines even integrate sensors that trigger alarms or safety shutdowns if an issue is detected. This high level of automation makes the equipment easy to operate and minimizes the dependency on skilled labor. It also reduces human error, ensuring more consistent results (truly an “intelligent control” approach to recycling).

Durability and Reliability: High-quality granulating lines are built with robust materials and engineering, ensuring they can operate continuously for years with minimal downtime. Durable construction (for instance, abrasion-resistant screw barrels for handling filled materials, or sturdy gearboxes) means less frequent repairs. Reliable operation is crucial when running a recycling plant 24/7. It also contributes to a faster return on investment because the machine stays productive for a long time without major overhaul.

Low Maintenance & Easy Cleaning: Along with durability, the design of modern lines considers easy maintenance. Quick-access components, self-cleaning screen changers, and effective degassing mean the system can run longer between maintenance intervals. When maintenance is needed, features like slide-plate screen changers or split-barrel extruders simplify the process. Less downtime for cleaning or part replacement keeps the productivity high.

Safety and Environmental Compliance: Another advantage is that reputable manufacturers design these lines with safety features (covers, interlocks, emergency stops) and environmental compliance in mind (for example, efficient filters to prevent dust or odor emissions). This ensures that your recycling operation can meet workplace safety standards and environmental regulations with ease.

Choosing the Right Granulating Line for Your Needs

Input Material and Contamination Level: First, identify the types of plastic you will process (e.g., PE film, PP rigid plastics, PET bottles) and how clean they are. Different materials may require specific features – for example, hygroscopic materials like PET might need vacuum degassing, or very contaminated farm plastics might need a robust two-stage extruder with intensive filtration. Ensure the chosen line is compatible with your input materials and can handle any dirt, labels, or moisture present.

Output Capacity: Determine the throughput you need (kg or tons per hour). Choose a line that meets your production capacity without strain. It’s wise to pick equipment that can slightly exceed your current needs so you have room to grow or handle surges in supply. Keep in mind that actual throughput can depend on material type and condition, not just machine specs.

Pellet Quality Requirements: Think about what quality of pellet your end-users or downstream processes require. If you need very uniform pellets with low moisture and certain bulk density, you might require additional features like an improved pellet cutter, extra cooling, or precise melt filtration. For instance, if the recycled pellets will be used in high-end applications (like food-grade packaging or fine filament production), investing in better filtration (e.g., automatic self-cleaning filters) and efficient drying systems is crucial to achieve the necessary pellet quality.

Energy Efficiency: Check the energy consumption per unit output for the line. As energy costs rise, a line with low power consumption per kg of plastic processed can save a lot of money in the long run. Look for features like insulated barrels, energy-efficient motors, and optimized heating/cooling which contribute to an energy-saving operation.

Level of Automation and Control: Decide how automated you want the process. Higher automation (PLC control, touch screens, auto adjustments) typically means a more user-friendly operation with fewer operators needed. If you prefer real-time monitoring, recipe saving, remote diagnostics, and integration with other smart factory systems, ensure the line’s control system is up to date. Automation can increase the upfront cost but will improve consistency and reduce labor costs.

Maintenance and Support: All machines need maintenance, so consider how easy it is to service the line and the availability of spare parts. Opt for designs known for quick screen changes and easy clean-out. Also, consider the manufacturer’s support: do they offer installation, training, and fast after-sales service? A reliable supplier (like Boxin Machinery, with a professional team and 20+ years of industry experience) will provide better long-term support in troubleshooting and parts supply. This is a significant factor in maintaining high uptime.

Footprint and Installation: Make sure you have enough space and the necessary infrastructure (power supply, water supply for cooling, etc.) in your facility. Some high-capacity lines can be quite large. Check if the line’s layout can fit your plant and whether any custom layout design is offered.

Budget and Return on Investment (ROI): Finally, consider your budget but balance it with the value you’re getting. A cheaper, underspec’d machine might become a bottleneck or incur high maintenance costs later. It’s often worth investing a bit more in a quality line that will run stably for years and pay back through efficiency and durability. Calculate the ROI by factoring in savings from using recycled pellets, reduced waste disposal costs, and any revenue from selling pellets if applicable.

Every recycling operation is unique. It may be beneficial to consult with the equipment manufacturer or an industry expert by sharing your specific requirements (type of plastic, volume, end-use of pellets) so they can recommend a tailored solution. For instance, Zhangjiagang Boxin Machinery offers customized plastic recycling solutions and can configure granulating lines to match different client needs, thanks to their extensive experience in this field. Taking the time to choose the right granulating line will ensure you get a system that is efficient, cost-effective, and aligned with your business goals.

EN

EN

English

English 简体中文

简体中文 Русский

Русский España

España عرب .

عرب .