What is a Plastic Crusher?

As the foundational core equipment in the plastic recycling industry, the Plastic Crusher (industry-wide also known as a Plastic Granulator or Grinder) is a high-efficiency machine designed specifically for material size reduction. Its strategic importance lies in its role as the critical bridge connecting waste collection with subsequent washing and pelletizing processes, serving as the starting point of the entire recycling flow.

Its core function is to transform bulky plastic waste—such as bottles, pipes, containers, and sheets—into uniformly sized granules or "regrinds" through high-speed shearing action. The typical output size ranges from 3mm to 20mm. This uniformity is crucial as it directly determines the stability and efficiency of downstream processes like washing, drying, and extrusion pelletizing.

The range of materials a plastic crusher can process is extensive, primarily covering two major categories:

-

Thermoplastics: PE (Polyethylene), PP (Polypropylene), PVC (Polyvinyl Chloride), PET (Polyethylene Terephthalate).

-

Engineering Plastics: ABS (Acrylonitrile Butadiene Styrene), Nylon/PA (Polyamide), PC (Polycarbonate).

Working Principle: High-Speed Shearing and Screening

|

The efficacy of a plastic crusher is rooted in a simple yet powerful mechanical principle. Understanding this principle is key to grasping its design essence and application advantages. The entire crushing process is primarily completed through two core steps: |

-

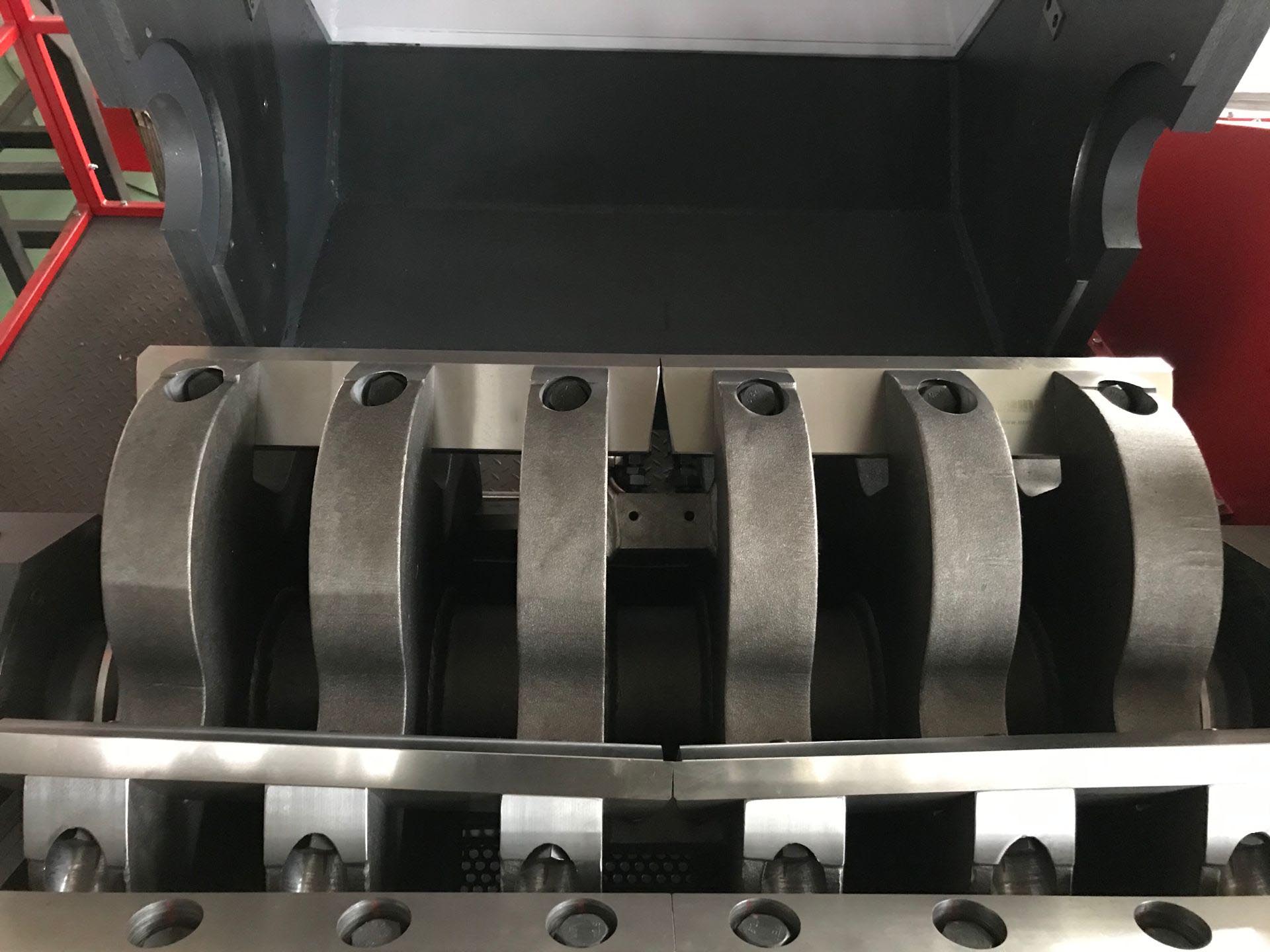

Shearing Action: Upon entering the cutting chamber, the plastic material is immediately subjected to intense shearing stress. This force originates from the rapid, staggered scissoring action between multiple rotary knives (mounted on the high-speed rotor) and stationary knives (fixed to the housing). It operates like countless scissors working simultaneously to rapidly comminute the material.

-

Screen Filtering: A screen with a specific aperture size is installed at the bottom of the cutting chamber. During the continuous shearing process, material can only pass through and discharge when its size is smaller than the screen mesh. This design ensures highly uniform output dimensions, providing a reliable guarantee for the stability of subsequent extrusion and pelletizing processes.

Core Advantages of Modern Plastic Crushers

(I) Optimized Rotor Design To maximize crushing efficiency for different materials, modern crushers employ specific rotor and knife configurations.

-

Claw Blade: The optimal choice for hard, heavy-duty materials. Its design possesses extremely high impact resistance, making it suitable for crushing large plastic chunks, thick-walled pipes, and sheets.

-

Flat Blade: The ideal design for thin-walled products, such as various plastic bottles, containers, and hollow blow-molded drums.

-

Slice/Flake Blade: Designed specifically for soft materials like LDPE films and woven bags. Its unique structure effectively prevents soft materials from wrapping around the rotor axis during high-speed rotation, ensuring a smooth crushing process.

(II) High Durability Materials Blade material is a key factor determining operational stability and maintenance costs. High-end equipment universally adopts high-quality alloy tool steels such as D2. D2 material undergoes professional cryogenic treatment, achieving a hardness of 58-62 HRC. Compared to ordinary steel, it wears slower and requires less frequent replacement, thereby reducing downtime.

(III) High Energy Efficiency and Low Noise

-

Energy Efficiency Design: Modern models generally adopt a V-belt drive design. Compared to older direct-drive systems, this design effectively buffers the motor startup load and reduces energy consumption during operation, achieving energy savings of 20-30%.

-

Noise Reduction: By equipping soundproof hoppers and utilizing double-layer housing structures, the operating noise of modern crushers is effectively controlled below 85 dB. This not only improves the workshop environment but also complies with international environmental and occupational safety standards.

Key Technical Parameters (Structural Data)

To translate theoretical performance into actual productivity, one must quantify the core technical parameters. These data points not only define the machine's limits but are also the key decision-making basis for matching the most suitable equipment to specific recycling tasks.

| Parameter | Specification Range | Description | Impact on Production |

| Motor Power | 5.5 kW - 75 kW+ | Determines rotor torque and cutting ability. 37kW+ is typically used for centralized, high-volume recycling. | Higher power provides stronger torque, critical for processing high-density or thick-walled materials without jamming. |

| Rotor Speed | 400 - 650 RPM | High-speed rotation ensures clean shearing rather than tearing, while minimizing frictional heat. | High RPM ensures efficient, clean cutting and prevents plastics from melting/sticking due to frictional overheating, which would block screens and interrupt production. |

| Throughput | 100 - 1500 kg/h | Core productivity indicator, influenced by material density, screen size, and blade sharpness. | Directly reflects equipment efficiency. E.g., using Slice Blades for films prevents wrapping, maximizing actual throughput. |

| Screen Size | Φ6mm - Φ20mm | Directly controls the size of the final output granules. | Smaller apertures yield finer granules but typically reduce throughput per unit of time. |

| Blade Material | D2 Tool Steel | Key to resisting wear, especially when processing abrasive plastics containing glass fibers. | Quality material directly correlates to blade lifespan, maintenance cycles, and long-term OPEX. It is a prerequisite for stable operation. |

Application Scenarios

The value of plastic crushers is most fully realized in two major recycling closed loops: Post-Consumer and Post-Industrial.

(I) Plastic Recycling Plants (Post-Consumer Recycling - PCR) In large-scale waste plastic washing lines, the crusher is indispensable. It efficiently crushes baled, dirty waste plastics mixed with sand and soil into uniform regrinds. In such applications, Wet Crushing technology is widely adopted. This involves injecting water into the chamber during the crushing process, offering dual benefits:

-

Pre-washing: The water flow rinses off some surface soil and impurities.

-

Cooling Tools: Water effectively absorbs heat generated by cutting, cooling the blades to significantly extend their lifespan and reduce dust.

(II) Injection & Blow Molding Factories (Post-Industrial Recycling - PIR) In production facilities, the crusher is the core equipment for achieving "Closed-Loop Recycling." Factories use it to process production waste (such as sprues, runners, and defective products) on-site. This immediate internal recycling model offers significant economic benefits. The resulting regrinds can be directly mixed with virgin material for new production batches. Statistics show this practice can help manufacturers reduce raw material costs by up to 40%.

Operation & Maintenance Guide

Continuous, preventive maintenance is the only way to maximize the lifespan, safety, and efficiency of a plastic crusher. Adhering to a regular maintenance schedule prevents costly unplanned downtime and ensures consistent output quality.

Blade Gap Adjustment

-

Action: Regularly check the gap between rotary and stationary knives. For soft films, maintain a tight gap (0.1-0.3mm); for rigid plastics, a slightly larger gap (0.5-1.0mm) is required.

-

Reason: Incorrect gaps lead to low cutting efficiency, high fines/powder rates, and increased energy consumption.

Belt Tension

-

Action: Check V-belt tension weekly without exception.

-

Reason: Belt slippage causes severe energy loss and can lead to overheating and premature belt failure.

Bearing Lubrication

-

Action: Grease bearings every 500 operating hours.

-

Reason: This is critical to prevent bearings from seizing due to overheating or catastrophic failure, especially in dusty recycling environments.

Feed Control

-

Action: Strictly prohibit overfeeding that causes overload. Automated equipment like conveyor belts is recommended to maintain a uniform, continuous feed rate.

-

Reason: Uniform feeding prevents instantaneous motor current spikes and rotor jamming, which is the prerequisite for smooth equipment operation.

EN

EN

English

English 简体中文

简体中文 Русский

Русский España

España عرب .

عرب .