|

|

In the plastics recycling industry, purity dictates the value and application potential of final recycled materials (rPET, rPE, rPP). However, recyclers face daily challenges with stubborn contaminants that simple washing cannot eliminate: tenacious label adhesives and organic residues on PET bottles, dirt and paper labels embedded within PP/PE film fibers, and sand or debris adhering to all material types. |

Many recycling processes rely on traditional cleaning methods, such as soaking pools or Sink-Float Tanks. However, these methods are inherently passive. The core function of a Sink-Float Tank is material separation based on density differences—for instance, PET flakes (density > 1) sink, while PP/PE caps and labels (density < 1) float. While critical for segregating different plastic types, this process is not an efficient cleaning step. Relying on gentle hydraulic agitation, it is largely ineffective against stubbornly adhering contaminants.

This is where the Friction Washer plays a critical role. The Friction Washer is not designed for mere "rinsing"; it is engineered for active, high-intensity "scrubbing." It utilizes powerful mechanical forces to physically decontaminate plastic surfaces, rather than relying solely on water or chemicals.

Mechanical Principles Deep Dive: Engineering Design of the Friction Washer

The High-Speed Rotor: The Cleaning "Engine"

|

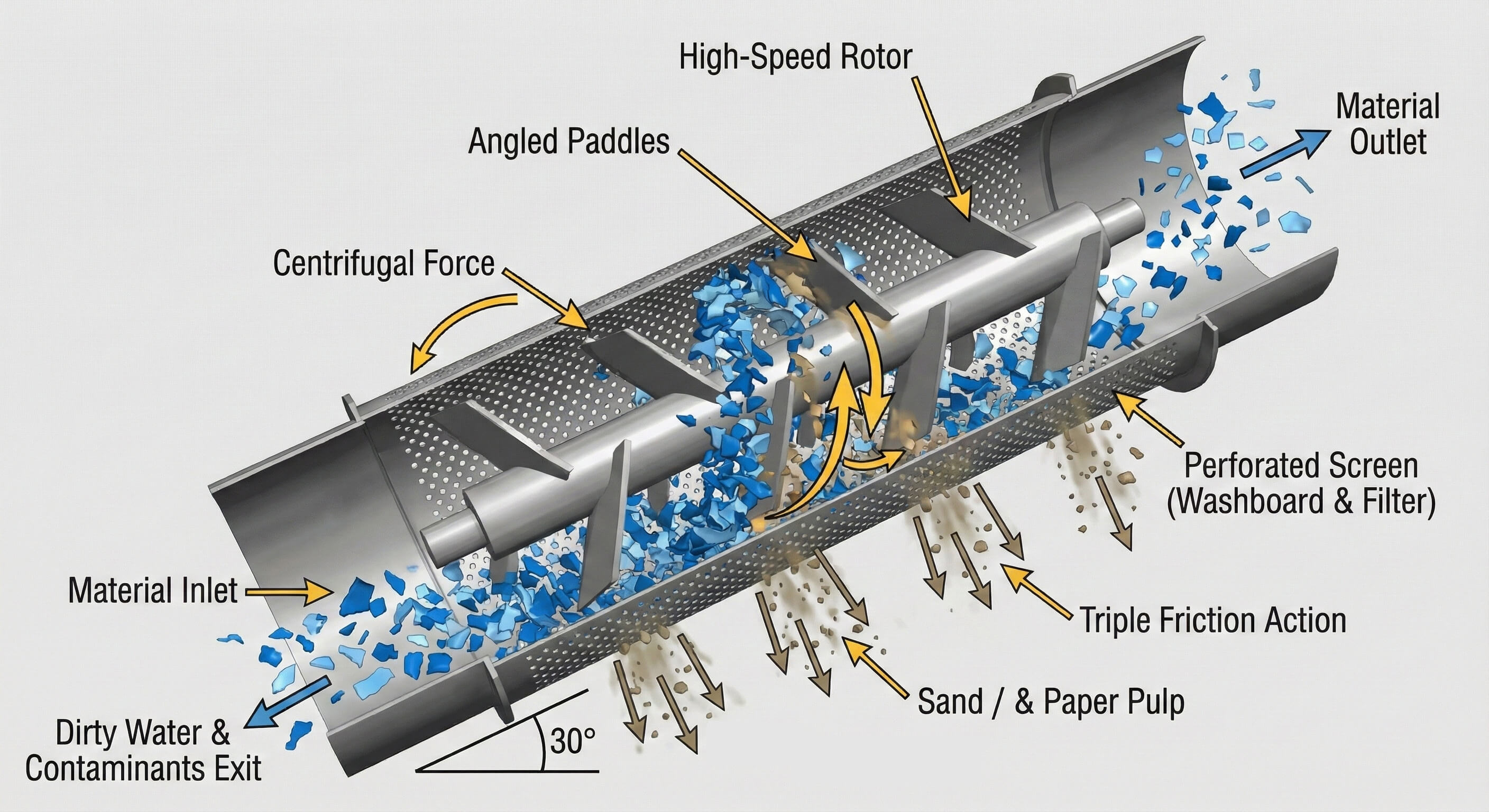

At the core of the Friction Washer lies a long-shaft rotor operating at extremely high speeds. The significance of this high velocity extends far beyond simple "rapid agitation." Its true engineering objective is to generate powerful centrifugal force. As the rotor spins, all material within the chamber—whether PET flakes or PE film scraps—is propelled by immense inertial force against the stationary outer screen. |

Consequently, high RPM is a prerequisite for activating the third (and most critical) point of the "triple friction" mechanism: material-against-screen. Without the centrifugal pressure generated by this speed, the material would merely tumble in the water; instead, it is firmly pressed against the screen, primed for the high-intensity abrasion to follow.

Angled Paddles: The Union of Transport and Agitation

|

Mounted on the high-speed rotor is an array of "slanted/tilted paddles." The design of these paddles embodies sophisticated engineering, serving a dual and synergistic function: acting simultaneously as an "agitator" and a "screw conveyor." |

Agitation Function (Explicit): The paddles rotate at high speeds, continuously striking and agitating the material. This is the most direct source of friction, ensuring the material is thoroughly mixed and subjected to mutual friction within the chamber.

Conveying Function (Implicit): Friction Washers are typically installed at an incline. Material must "ascend" from the lower inlet to the upper outlet. The "tilt angle" of the paddles is precisely calculated. While agitating the material at high speeds, it also "pushes" and "transports" the material upward, enabling stable passage through the entire chamber against gravity.

The Perforated Screen: "Washboard" and "Filter"

The entire high-speed rotor is encased by a "perforated screen" or "mesh screen tunnel." This screen serves a dual role:

As a Filter (Separation):under the centrifugal force generated by high rotation speeds, water and detached contaminants (such as dirt, sand, and pulp) are forcibly expelled through the screen perforations.

As a Washboard (Friction): The screen itself acts as a stationary, abrasive surface. When material is tightly pressed against the screen by centrifugal force, it functions as the ultimate "washboard."

The Inclined Structure: Calibrating "Residence Time"

Virtually all Friction Washers feature an inclined installation, typically ranging from 15° to 35°-45°. The fundamental objective of this design is to precisely control the material's "Residence Time" within the chamber.

Material enters at the "lower end" and discharges from the "upper end." This necessitates that the material must "ascend" to exit. The angle of inclination serves as a critical, adjustable engineering parameter used to balance cleaning intensity against throughput:

Steeper Angle (e.g., 45°): The ascent is more difficult, resulting in a longer residence time and increased exposure to paddle impacts and friction. This configuration is suitable for heavily contaminated material requiring more rigorous cleaning.

Shallower Angle (e.g., 15°): Material passes through more rapidly, resulting in a shorter residence time and higher throughput. This is appropriate for lightly contaminated material or processes where the primary goal is rapid rinsing (e.g., rinsing following a PET hot wash).

Core Insight: Unlocking the Cleaning Power of "Triple Friction"

Friction Force I: Material-on-Material In the turbulent environment generated by high rotational speeds and paddle agitation, thousands of plastic flakes or film scraps collide, compress, and rub against one another. Industry reports confirm that "friction between PET flakes aids in removing dirt and debris," as the process "forces plastic flakes and films... to rub against each other at high speeds." This is analogous to vigorously shaking muddy pebbles in a sack; they abrade one another, rendering surfaces smooth and clean.

Friction Force II: Material-on-Paddles This represents the most direct mechanical action. The high-speed rotor paddles (referred to as "screws" in certain designs) continuously "strike" and "scrub" the material. In specific systems, this generates "intense friction between the rotor tools and the screen basket." While the mechanism resembles the agitation of a washing machine, its velocity and intensity are magnitudes higher, effectively stripping away stubbornly adhering contaminants.

Friction Force III: Material-on-Screen This is the most potent friction force, driven by high-velocity centrifugal force and constituting the essence of the Friction Washer. The material does not float freely within the chamber; rather, it is tightly "pinned" against the stationary outer screen by centrifugal force (see 2.A). Simultaneously, the rotating paddles force the material to "scrape" across the screen surface. As "plastic is continuously rotated against the screen," centrifugal force "presses the plastic flakes against the mesh. The resulting friction between the flakes and the screen abrades away contaminants."

Key Application (I): The "Final Polish" for PET Flake Washing Lines

In PET bottle (e.g., beverage and water bottles) recycling lines, the Friction Washer plays a vital role in post-processing or "finishing."

Line Placement: In the PET recycling process, the Friction Washer is typically positioned downstream of the "Hot Washing Tank."

Core Tasks: The primary objective of PET hot washing (typically using Caustic Soda/Lye at 85-95°C) is to dissolve label adhesives and remove grease. The Friction Washer (operating as a cold wash unit following the hot wash) has two critical missions:

-

Physical Removal: Physically removing adhesive residues and organics that were "loosened" during the hot wash via "Triple Friction."

-

Chemical Balance: This is a critical yet often overlooked function. The hot washing process exposes flakes to Caustic Soda (Lye). If these highly alkaline chemicals remain, they will severely compromise the final quality and pH value of the rPET.

Therefore, within a PET bottle recycling washing line, the Friction Washer acts not only as a "cleaner" but also as a "neutralizer." Through vigorous friction and freshwater rinsing, it "effectively reduces the pH value of the flakes." Customers utilize Friction Washers in PET lines not merely to remove dirt, but to ensure the total removal of chemical residues from the hot wash, achieving a "final polish" that meets high-quality standards (e.g., food-grade or filament-grade).

Key Application (II): The "Heavy-Duty Scavenger" for PP/PE Film Washing Lines

Distinct from its "finishing" role in PET lines, the Friction Washer serves as a rugged, frontline "heavy-duty scavenger" in PP/PE film (e.g., agricultural and packaging film) lines.

The Challenge: Post-consumer film is typically heavily contaminated with sand, sludge, and the most difficult contaminant to handle—paper labels. While paper becomes soggy in water, it remains adhered to the film surface, making separation in Sink-Float Tanks impossible.

Core Tasks: Addressing "High Contamination" and "Paper" issues.

Here, the Friction Washer demonstrates its powerful mechanical capabilities. When film and paper enter the high-speed chamber together, the intense friction does more than "clean" the paper; it mechanically "destroys" paper contaminants. Studies confirm that this friction "causes paper and cardboard to break down into tiny fibers," effectively turning them into "paper pulp."

Once the paper is pulped, this slurry-like contaminant is immediately expelled through the screen by centrifugal force.

Consequently, in film lines, the Friction Washer functions as a hybrid "shredder" and "separator." It resolves paper contamination issues that Sink-Float Tanks cannot address. This explains why technical guides emphasize that film washing lines "rely heavily on" Friction Washers for "intensive scrubbing."

What Sets Modern Friction Washers Apart

Not all friction washers are capable of performing the tasks described above. The distinction between merely "functional" and truly "exceptional" lies in a deep understanding of application scenarios and precise design details. Exemplified by (Boxin's) design philosophy, industrial-grade equipment must meet the following standards:

A. Speed and Efficiency Rotational speeds of 1000+ RPM form the foundation for intense friction and efficient centrifugal separation. This serves as the physical prerequisite for activating "Triple Friction," particularly the critical "material-on-screen" action.

B. Water-Saving Design

-

Myth: More water equals cleaner material.

-

Fact: Modern designs (Boxin) utilize a "non-fully immersed structure." Cleaning power derives primarily from "friction," not "water volume." Water functions solely to lubricate, transport separated contaminants, and keep the screen clear.

Consequently, "targeted spraying" proves smarter and more efficient than "full immersion." It applies water precisely where needed, significantly minimizing total water consumption and the substantial energy required for subsequent drying stages.

C. Durability Friction Washers operate in harsh environments characterized by moisture, high speeds, high impact, and intense abrasion (from sand and debris). Therefore, critical components in contact with material—such as screens, bearings, and the chamber—must be fabricated from high-quality Stainless Steel. This ensures superior corrosion and wear resistance, extending the machine's operational lifespan.

D. Core Advantage: Customizability As demonstrated in Sections 4 and 5, the Friction Washer performs distinct roles in PET lines (finishing/neutralization) versus PE film lines (heavy-duty scrubbing/pulping). Consequently, "one-size-fits-all" standard equipment cannot achieve optimal results across both applications.

True "solution providers" offer customizable configurations. (Boxin) provides "customizable barrel lengths, blade (paddle) arrangements, and screen densities."

-

Barrel Length dictates Residence Time.

-

Paddle Arrangement dictates Friction Intensity.

-

Screen Density dictates Separation Particle Size.

This capability allows for the precise engineering of friction physics tailored to specific contaminants (e.g., "high oil" or "high paper pulp content"). It demonstrates that solutions are designed based on a profound understanding of the recycling process, rather than merely "manufacturing standard equipment from blueprints."

Comparative Application of Friction Washers in Major Recycling Lines

| Feature | PET Flake Washing | PP/PE Film Washing |

| Primary Objective | Final Polishing & Chemical Neutralization | Heavy-Duty Scrubbing & Contaminant Pulverization |

| Line Position | After Hot Washing Tank | After Crusher/Pre-wash |

| Key Removals | Residual Caustic (Lye), Loosened Adhesives, Organics | Embedded Dirt, Paper Labels, Organics |

| Core Function | Reduce & Balance pH; Enhance Flake Purity | Separation of Impurities |

| Primary Mode | Intensive Cold Rinsing | Intensive Mechanical Friction |

Conclusion: The "Workhorse" of Every High-Purity Washing Line

The Friction Washer is not an "option"; it is the absolute cornerstone of achieving high-purity materials in modern plastic recycling. By leveraging high speeds, "Triple Friction," and centrifugal force, it eliminates stubborn contaminants that simple soaking or rinsing cannot address.

Whether serving as the "finishing" and "neutralizing" unit in PET lines to ensure bottle-to-bottle purity, or acting as the "heavy-duty scavenger" in PE/PP film lines to mechanically pulp paper and scrub away tenacious dirt, it remains an irreplaceable "workhorse."

(Boxin) recognizes this equipment as a pivotal component bridging the major recycling domains of PET and film. Investing in a Friction Washer precisely engineered for your specific contaminants is the most crucial step toward optimizing total line efficiency and maximizing final product value.

EN

EN

English

English 简体中文

简体中文 Русский

Русский España

España عرب .

عرب .