EU Regulation 2025/40 (PPWR), adopted in late 2024 and fully effective in 2025, currently serves as the primary benchmark guiding global plastic recycling machinery design. Distinct from previous Directives, this Regulation exercises direct legal binding force on all EU member states, with its impact rapidly extending across the global supply chain.

The Regulation explicitly mandates that, effective January 1, 2030, plastic packaging—excluding contact-sensitive packaging (e.g., food and cosmetics) and specific exemptions—must incorporate a minimum of 35% recycled content. This requirement has directly triggered an explosive demand for high-quality rHDPE.

Physical Basis for Differentiated Configuration of HDPE Rigid Plastic Recycling Lines

The starting point for mechanical configuration is always a profound understanding of the feedstock. As a polymer characterized by high crystallinity and strong chemical resistance, the primary challenge in recycling HDPE lies not in the polymer itself, but in the contaminants it carries and its composite structures.

Recycling plants typically procure pre-processed and baled HDPE feedstock from Material Recovery Facilities (MRFs). The common types of HDPE bales are listed below:

Post-Consumer Milk and Beverage Bottles

This represents the most high-value recycling stream, commonly referred to within the Chinese market as "Big White" (Da Bai) or "Small White" (Xiao Bai) material.

Physical Properties: Thin-walled and hollow structures with low bulk density (prior to baling). They are easy to shred, and natural (uncolored) HDPE is more versatile due to its ease of dyeing for reuse.

|

|

Primary Contaminants: Organic Residues: Fats, proteins, and sugars. Label Systems: Paper labels (prone to pulping), PP self-adhesive labels, and PVC shrink films. Adhesives: Hot melt and water-based adhesives. Aluminum Foil: Most milk bottles utilize aluminum foil seal liners. Caps: The recycling process requires a mono-material PE stream, whereas most bottle caps are made of PP. |

Mixed Rigid Bales (Mixed Color Daily Chemical Bottles)

This is a high-value recycling stream second only to milk bottles (typically consisting of blow-molded bottles for laundry detergent, shampoo, bleach, and other household cleaners). In China, it is commonly referred to as "Hua Yi Liao" (Mixed Color PE).

Industrial Packaging & Chemical Drums

Typically sourced from blue chemical drums, lube oil containers, or IBC totes.

|

Physical Properties: Characterized by thick walls, high strength, and extreme toughness. These materials tend to tumble and idle within the crushing chamber; therefore, a shredder is usually configured for primary size reduction. Primary Contaminants: Hazardous Chemicals: Residues may include hazardous waste such as pesticides, strong acids/alkalis, organic solvents, and lubricants. |

Industrial Injection Molding Grade Rigid Plastics (Crates/Pallets/Pipes)

|

Physical Characteristics: Solid structure with uneven wall thickness, often featuring reinforcing ribs. Prolonged outdoor exposure frequently results in a surface photo-oxidative degradation layer and brittle texture. Primary Contaminants: Inert Impurities: Mud, dust, nails (in pallets), and metal hinges. Polymer Impurities: PP (handles, clips) and rubber anti-slip pads. Due to the minimal density difference between PP and HDPE (0.90–0.96), traditional sink-float separation is ineffective. |

Comprehensive Industrial Equipment for HDPE Scrap Plastic Recycling

HDPE Shredder Machine

|

Single Shaft Shredder machine |

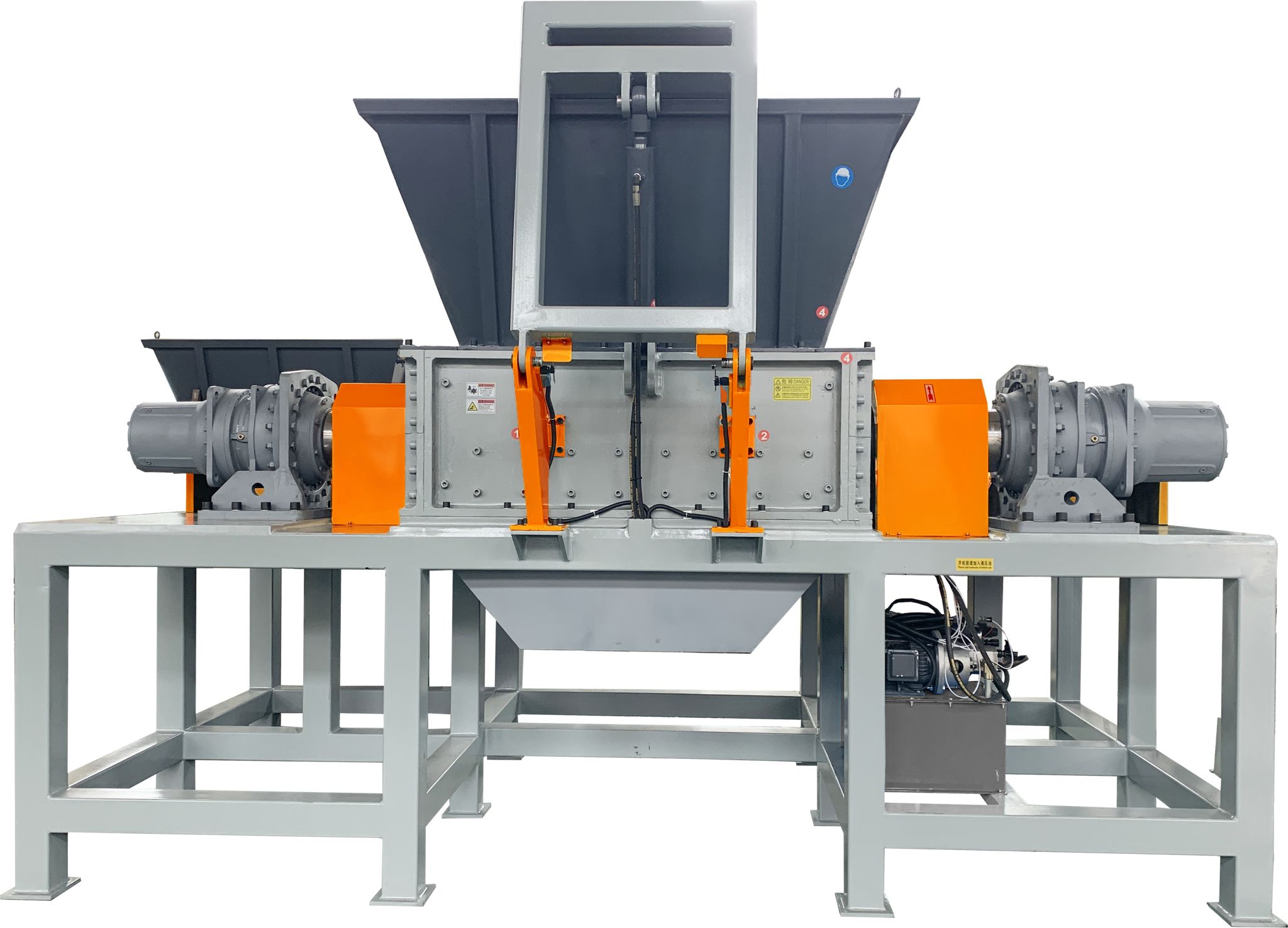

Double Shaft Shredder machine |

|

Working Principle |

High-speed rotor cutting + Hydraulic ram + Fixed screen |

Two low-speed, high-torque shafts intermeshing and tearing |

|

Output Size |

Uniform, determined by screen aperture (e.g., 40mm) | Irregular strips, typically without screen control |

|

Application Scenarios |

Purge lumps, thick-walled pipes, injection molding scrap, high-density chunks | Hollow containers (drums, bottles), baled materials, bulky materials difficult to feed |

|

Energy Efficiency Analysis |

High cutting efficiency, but sensitive to foreign objects (metals) | Extremely high torque, impact-resistant, suitable for primary shredding |

For processing baled chemical drums, a twin-shaft shredder is highly recommended for primary shredding due to its effective gripping of bulky hollow materials, low noise, and minimal dust generation. It should be followed by a wet/dry granulator for fine crushing.

HDPE Granulator Machine

|

Wet Granulator Machine |

Dry Granulator Machine |

|

Working Principle |

High-speed rotor drives rotary and stationary knives to generate shear force, with continuous circulating water injection into the crushing chamber. |

High-speed rotor drives rotary and stationary knives to generate shear force; no water injection. |

|

Output Size |

Uniform, determined by screen aperture (e.g., 12mm). |

Uniform, determined by screen aperture (e.g., 12mm). |

|

Application Scenarios |

Recyclables suitable for sale after simple washing. |

Uncontaminated in-house scrap; equipped with an air extraction system and silo for direct bagging. |

Blade Metallurgy: Due to the wet processing environment and high-wear characteristics, verify that the blade material is D2 (AISI D2) or SKD11 tool steel. Following cryogenic treatment, these high-carbon, high-chromium steels achieve a hardness of HRC 58-60, offering superior wear and corrosion resistance to prevent chipping and extend sharpening intervals.

Maintenance Design: Check for a hydraulic system to facilitate rapid cleaning or screen replacement without dismantling the entire hopper, thereby minimizing downtime.

HDPE Scrap Recycling Washing Line

|

|

Friction WasherThe high-speed friction washer utilizes centrifugal force and paddle impact to remove stubborn contaminants.RPM Specifications: Typically above 1000–1200 RPM. Working Principle: Materials are subjected to high-speed centrifugal force and friction between the screen and paddles. Contaminated water, paper pulp, and sediment are discharged through the screen, while the plastic advances. |

|

|

Sink-Float Tank Utilizes water density (1.0 g/cm³) for physical separation.

|

|

Hot Washer System This is a critical step for removing grease, adhesives, and odors, particularly for milk bottles and household chemical containers. Chemical Regimen:

|

|

Centrifugal Dryer

|

|

Hot Air Drying

|

|

Air Classifier (Zig-Zag / Air Classifier) Utilizes aerodynamic principles to remove light-density impurities.

|

|

Optical Sorter NIR (Near-Infrared) Sorting: Sorts materials based on polymer spectral signatures.

Vis (Visible Light/Color) Sorting: Utilizes CCD cameras for color rejection.

|

HDPE Scrap Pelletizer Machine

|

||

| Feature | Single Stage Extruder | Double Stage Extruder (Mother-Baby) |

| Structure | Single long screw (L/D 30-36:1) | Two in series: Primary extruder (plasticization/degassing) + Secondary extruder (pressure build-up/filtration) |

| Degassing Capacity | Single vent port; limited volatile removal capacity. | Dual vacuum degassing zones. The large surface exposure at the connection between the primary and secondary units ensures excellent devolatilization. |

| Filtration Capacity | Single filtration. High back pressure can compromise plasticization. | Double filtration. Primary coarse filtration (protects secondary unit) + Secondary fine filtration (ensures quality). |

| Melt Stability | Susceptible to raw material fluctuations. | Secondary unit operates at low speed to establish extremely stable die head pressure, yielding uniform pellet size. |

| Applicable Materials | Extremely clean post-industrial scraps; dry materials. | Post-Consumer Recyclates (PCR) containing higher moisture, ink, and volatiles. |

| TCO Analysis | Low initial investment, but average product quality and rapid screen consumption. | High initial investment, but produces dense, bubble-free pellets with higher market value and superior comprehensive ROI. |

Except for processing extremely clean post-industrial scrap, a double-stage extruder is a mandatory investment for any PCR project to guarantee end-product competitiveness.

Melt Filtration Technology

Filtration serves as the final barrier to intercept fine impurities (aluminum fines, grit, unmelted polymers).

-

Hydraulic Slide Plate: Low cost, but screen changes may cause pressure fluctuations or brief production halts.

-

Piston Type: Dual-piston designs allow for non-stop screen changing, ensuring continuous production; ideal for factories operating 24/7.

-

Scraper Filter: Designed for highly contaminated streams (e.g., high paper pulp content). Uses a rotating blade to continuously scrape impurities off the screen surface. While capital-intensive, it can handle contamination levels up to 5%, significantly reducing screen consumable costs.

Pelletizing System

-

Water Ring / Hot Die Face: The most common method for HDPE recycling. Pellets are cut hot at the die face and thrown into a cooling water ring. Features simple operation, high automation, and superior pellet shape.

-

Strand Pelletizing: The traditional method. Requires manual strand pulling and is prone to breakage. Due to high labor costs and instability, it is not recommended for high-capacity lines.

Master Configuration Matrix by Raw Material Type

To visually demonstrate the complex configuration logic mentioned above, the following table summarizes the ultimate reference for engineering selection:

| Functional Module | Class I: Milk/Detergent Bottles | Class II: Chemical Drums/IBCs | Class III: Injection Grade Rigids |

| Core Challenges | High-quality pure HDPE requires optical sorting. | High toughness, hazardous residue, bulky size. | Metals, PP impurities, rubber. |

| Size Reduction | Heavy-duty Wet Granulator | Twin-shaft Shredder + Wet Granulator | Heavy-duty Wet Granulator |

| Washing Medium | Hot Alkaline (NaOH) Wash | Multi-stage Rinsing + Multi-stage Friction Washing | Friction Washing |

| Sorting Tech | Sink-Float + Optical Sorting (Material, Color) | Sink-Float | Sink-Float |

| Drying Tech | High-speed Centrifugal + Hot Air Drying | High-speed Centrifugal + Hot Air Drying | High-speed Centrifugal + Hot Air Drying |

| Extruder Type | Double Stage (Strong degassing for ink removal) | Single/Double Stage | Single Stage |

| Filtration System | Piston / Scraper Type | Slide Plate / Piston Type | Slide Plate / Piston Type |

| Pelletizing | Water Ring | Water Ring / Strand | Water Ring / Strand |

EN

EN

English

English 简体中文

简体中文 Русский

Русский España

España عرب .

عرب .