PET bottle washing lines are essential equipment for recycling facilities—they take piles of discarded PET plastic bottles and turn them into clean, reusable PET flakes.

If you're looking for a PET washing line manufacturer to purchase a system or gather pre-purchase information, it's crucial to understand the landscape of suppliers and what they offer.

By the end, you'll be equipped to identify and compare manufacturers that can meet your recycling project’s needs, whether you run a small startup or a large industrial operation.

|

Caption: A fully assembled PET bottle washing line in a factory. These systems enable used plastic bottles to be cleaned and converted into high-quality PET flakes.

|

Comparing High-End, Mid-Range, and Budget Manufacturers

The market for PET washing line equipment is global and ranges from well-known high-end engineering companies to smaller low-cost machine makers. For clarity, it's helpful to categorize manufacturers into three broad tiers – High-End, Mid-Range, and Budget – based on the typical quality, technology, and price level of their offerings. Below we explore each category, along with examples of manufacturers (from around the world) in each segment:

High-End PET Washing Line Manufacturers

High-end manufacturers are typically based in industrialized countries (such as Europe, North America, and Japan), and are known for their cutting-edge technology, superior manufacturing quality, and comprehensive solutions. They serve large recycling companies or projects that prioritize performance and reliability over cost. These suppliers are capable of delivering turnkey systems with the highest purity outputs and extremely high throughput.

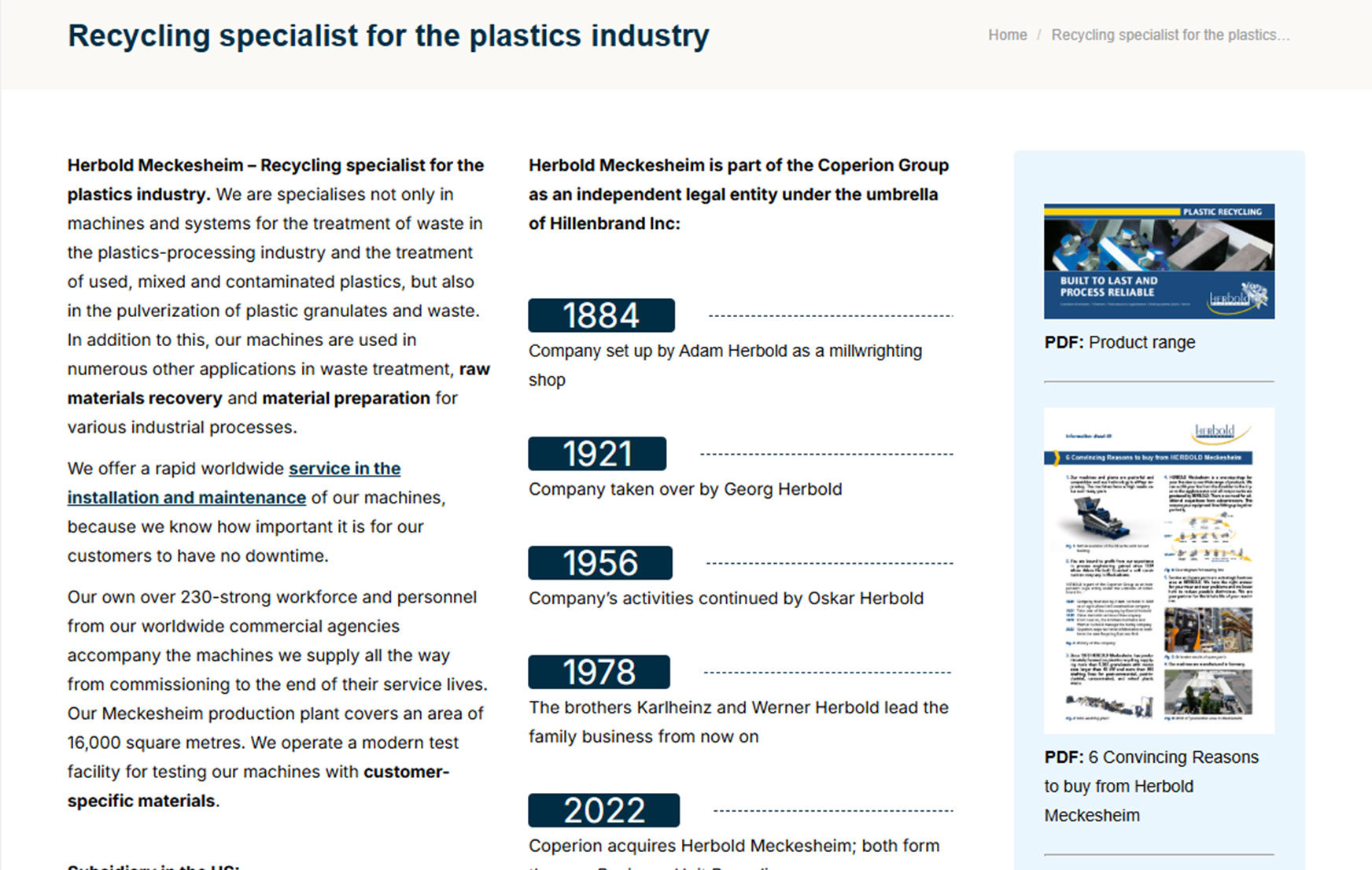

Herbold Meckesheim (Germany)

Sorema (Italy)

Starlinger (Austria)

Typically, these top-tier manufacturers offer a full-service package—from pre-sales plant design to installation, training, and long-term support—ensuring that every component (sorting, grinding, washing, drying, etc.) is optimized.

The trade-off is cost: high-end lines are the most expensive and are usually chosen by customers who need to process very large volumes (e.g., over 3–5 tons per hour) or require high-quality output for applications such as food packaging.

Mid-Range PET Washing Line Manufacturers

Mid-tier manufacturers occupy the middle ground, offering products that balance quality and cost. These companies are mostly based in regions such as mainland China, Taiwan, India, Eastern Europe, or South America, though some are small enterprises from developed countries. They primarily serve small to medium-sized recycling businesses or larger companies with budget-conscious strategies.

Equipment from mid-tier suppliers is reliable and performs well—often approaching the efficiency of high-end lines—but comes at a lower price. While they may not feature all the configurations of the most advanced systems, they use proven technologies and can even excel in specific areas such as energy efficiency or compact design.

Boxin Machery (China)

|

is a manufacturer that supplies fully automated PET bottle washing lines to customers in over 50 countries. Boxin’s systems are known for their modular, highly adaptable design, which allows production lines to be configured to handle varying levels of contamination and capacity while still achieving very high efficiency. Notably, Boxin’s standard PET bottle washing lines can produce flakes with extremely high purity, with residual contaminants controlled at ≤100 ppm—meeting food-grade standards. |

Panchal Plastic Machinery (India)

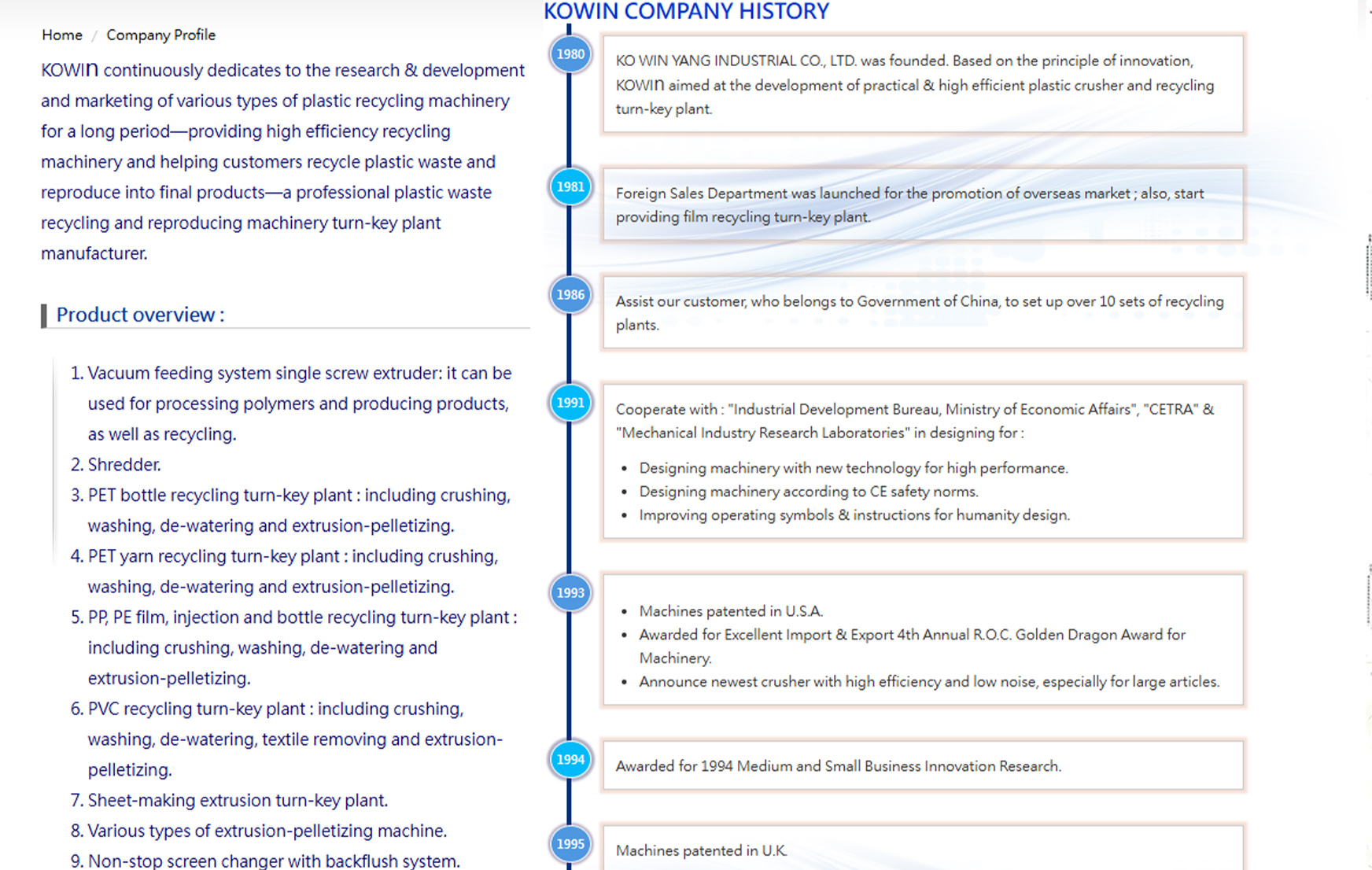

KOWIn (Taiwan)

Budget (Low-End) PET Washing Line Manufacturers

Within the budget range, some manufacturers offer the most affordable PET washing lines. These companies are often smaller or less experienced, typically located in China, other parts of Asia, or local machinery makers in some developing countries. These systems provide the basic functionality needed for PET washing, but there are important considerations to keep in mind.

Low-cost PET washing lines feature simpler designs and lower capacities. Such machines may omit advanced steps like automatic sorting or multiple hot washes—typically including just a basic crusher, a washing tank, a friction washer, and a dryer. Due to their low manufacturing cost, the materials may be less robust compared to mid- or high-end lines (e.g., thinner metal gauges, simpler bearings), and automation levels are lower, requiring more manual intervention.

This doesn’t mean they can’t get the job done; many small-scale recyclers successfully use budget machines to wash PET bottles on a modest scale. However, buyers should weigh the pros and cons: quality control and after-sales support at this tier may be weaker. Long downtimes or more frequent repairs are not uncommon with very cheap machines, and if the manufacturer lacks a global service network, technical support may be limited.

Key Factors in Choosing a PET Washing Line Manufacturer

Experience and Reputation:

How long has the manufacturer been producing plastic recycling equipment? A strong track record—years of experience and multiple installations—is a good indicator of technical expertise. Reputable manufacturers are known for delivering high-quality, durable machines and adhering to industry standards.

Product Quality and Performance:

Since a washing line is a major investment, robust construction (e.g., stainless steel components for the wet section) and reliable performance (high uptime, low failure rates) are essential. While high-quality machines may have a higher upfront cost, they offer better output and longer service life.

Capacity and Customization:

Ensure the manufacturer can supply a line that matches your required capacity. Top manufacturers customize equipment to meet your specific needs—e.g., adding extra sorting steps for heavily contaminated bottles or adjusting the system for different feedstocks (post-consumer bottles, industrial scrap, etc.). If you have special requirements—like handling extremely dirty bottles or integrating with existing systems—customization is critical. Check whether the supplier is flexible enough to modify standard line designs to suit your project.

After-Sales Support and Service:

A PET washing line is a complex system requiring ongoing maintenance and troubleshooting. Strong technical support from the manufacturer is vital. Consider whether the supplier provides installation services, staff training, and prompt after-sales service (such as spare parts availability and field technicians).

EN

EN

English

English 简体中文

简体中文 Русский

Русский España

España عرب .

عرب .