How Waste Plastic Recycling Washing Lines Execute the Circular Economy

A waste Plastic Recycling Washing Line is an integrated, automated mechanical system. Its fundamental purpose is to transform contaminated waste plastics collected from Post-Consumer and Post-Industrial sources into clean, high-purity raw materials (often called "plastic flakes" or "washed flakes") that can be used to manufacture new products.

The biggest challenge in recycling waste plastics is their high level of contamination and complexity. These contaminants include physical impurities (like dirt, sand, glass, metal), surface adherents (like food residue, oil stains), and material mixtures (like paper or plastic labels, glue, and different plastic types, such as the PP caps on PET bottles).

Therefore, an efficient plastic recycling washing line is core to a recycling enterprise's profitability. It directly determines the purity and quality of the final recycled materials (like rPET, rPE). This purity is the decisive economic factor: only clean plastic can be processed to produce high-quality recyclables. Recyclers, when assessing feedstock, divide it into high-value (target plastic), medium-value (mismatched plastics), and negative-value (waste). The economic function of the washing line is to, through systematic purification, transform "negative-value" or "low-value" contaminated raw materials into "high-priced" "contaminant-free PET flakes" , thereby achieving "Value Upcycling".

How Do Waste Plastic Recycling Washing Lines Work?

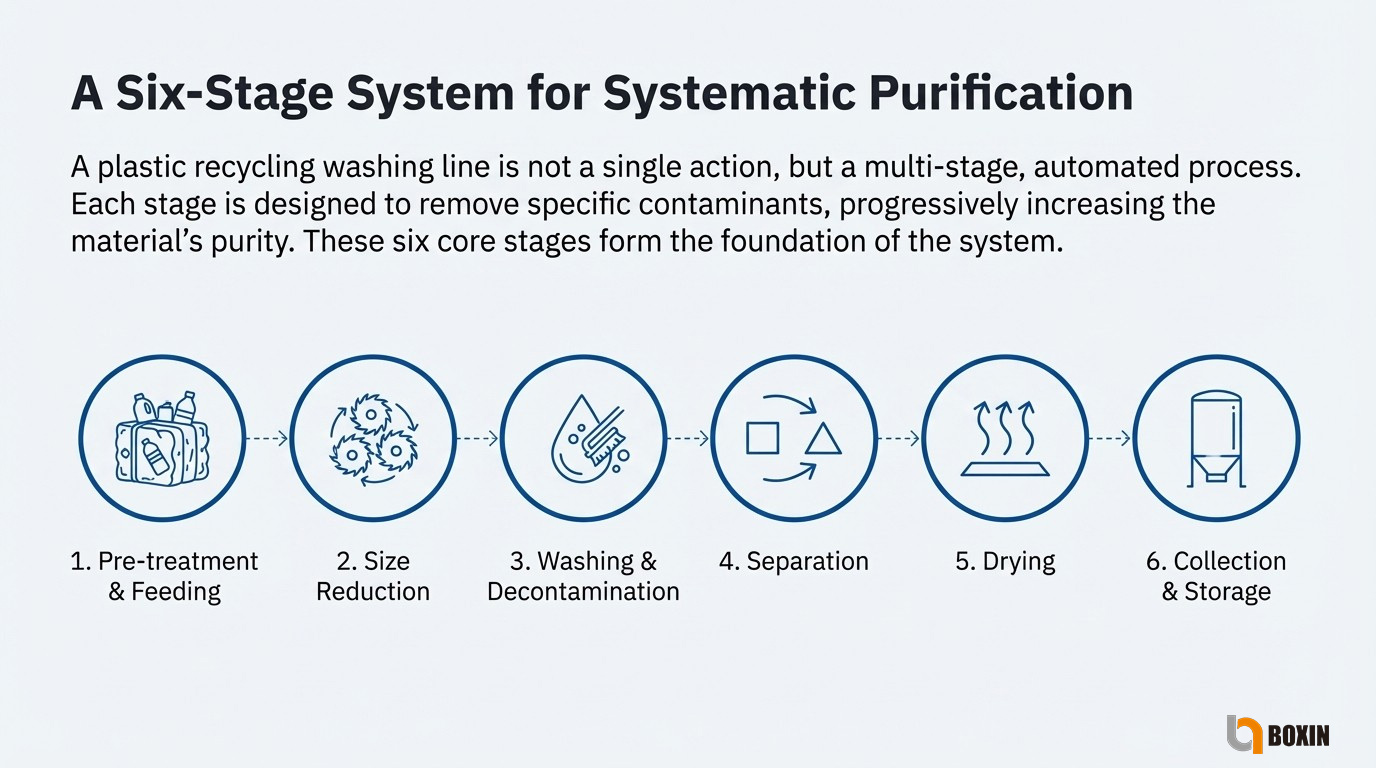

The working principle of a plastic recycling washing line is not a single "washing" action, but a multi-stage, systematic purification process. Each stage aims to remove specific types and sizes of contaminants. While specific configurations vary by raw material (see Chapter 4), a complete process typically includes the following six core stages, connected by conveyor belts or screw feeders to form an automated production line.

Stage 1: Pre-treatment & Feeding

The process begins with raw material preparation. Waste plastics usually arrive at the factory in highly compressed "bales."

-

Debaling: Material is first fed into a "Bale Breaker" / "Debaler," which breaks up the compacted plastic bales, forming a loose, continuous material stream. (Soft plastics-film materials can often be debled manually)

-

Preliminary Screening (Pre-Sorting): The loose material then passes through a "Trommel" or a Manual Sorting Conveyor. The trommel is a slowly rotating, perforated channel that allows smaller contaminants (like broken glass, metal, stones, dirt) to fall out, while the target plastics (like PET bottles) continue. Manual sorting is used to remove obvious large non-plastic contaminants or incorrect plastic types.

Stage 2: Size Reduction

To make cleaning more thorough and efficient, the whole bottles or large sheets of film must be broken down to increase their surface area.

-

Shredding or Crushing: The material is fed into a "Shredder" or "Granulator / Crusher".

-

Key Technology: Wet Granulation: Many modern lines use a "wet granulator". In this design, water is continuously sprayed into the cutting chamber. This has two purposes: first, to pre-wash the material and rinse off some dirt; second, to use water to cool the high-speed rotating blades, extending their service life. The crushed material is typically cut into small 10-15mm pieces (crushed material).

Stage 3: Washing & Decontamination

This is the core purification stage of the line, combining physical friction and chemical washing.

-

Friction Washing: The crushed flakes enter a "Friction Washer". This machine has high-speed rotating paddles or a rotor inside, forcing the plastic flakes to rub against each other and the machine walls, thus effectively "scrubbing" off surface-adhered sand, dirt, and most organics.

-

Hot Washing: For specific applications (especially PET bottle recycling), hot washing is essential. The material is sent to a "Hot Wash Tank" , where it is mixed with high-temperature water (usually between 85-95°C) and chemical detergents (like caustic soda/sodium hydroxide). The high temperature and stirring action can effectively dissolve label glue and remove stubborn oil stains and beverage residues.

Stage 4: Separation

The washed material is a mixture of multiple materials (e.g., PET flakes, PP cap fragments, paper label residue). The goal of the separation stage is to purify the target plastic.

-

Sink-Float Tank: This is the most core separation technique. This device is a large water tank that utilizes the density differences of various plastics. In PET bottle recycling, the denser PET plastic flakes will sink, while the less dense PP/PE plastics (from caps) and most label paper will float on the surface. The sinking PET flakes are collected by a screw conveyor at the bottom, achieving efficient separation.

-

Air Classification: To further remove light impurities, the material passes through an "Air Classifier" or "Zig-Zag Separator". A controlled stream of air blows past the falling plastic flakes, blowing away lighter contaminants (like dry paper label fines and plastic film dust) while the heavier, clean plastic flakes continue to fall.

Stage 5: Drying

To meet the requirements of subsequent processing (like pelletizing or injection molding), the moisture on the clean flakes must be removed to an extremely low level.

-

Mechanical Drying (Dewatering): First, the material is typically sent to a "Centrifugal Dryer". Through the centrifugal force generated by high-speed rotation, most of the surface moisture (about 95-98%) can be spun off.

-

Thermal Drying: They will enter a "Hot Air Drying System" from the centrifugal dryer, mixing with hot air in stainless steel pipes to remove the last residual moisture through evaporation.

-

Squeeze Drying: For PE/PP film, due to its large surface area and high water retention, a "Squeeze Dryer" is usually used. This device uses a special multi-stage screw design to "squeeze" moisture out of the film through powerful physical pressure, which can reduce humidity to below 3%.

Stage 6: Collection & Storage

The final step of the process is collecting the finished product. The clean, dry plastic flakes are conveyed to a "Product Silo" for temporary storage. From here, they can be automatically packed into jumbo bags, ready to be sold or transported to the next processing unit (such as a pelletizing line, which will melt them and make them into recycled plastic pellets).

Key Equipment Analysis: Deconstructing the Heart of the Washing Line

The overall performance of a plastic recycling washing line depends on the efficiency and reliability of its core components. For potential investors and operations managers, understanding the function of these key machines is fundamental to evaluating different supplier proposals.

Shredder vs. Granulator

Although both are used for "size reduction," their applications differ.

-

Shredder: describes it as a low-speed, high-torque device. It is designed to handle large, tough, or baled materials, such as HDPE drums, car bumpers, or compacted film bales. Its role is "coarse crushing" (e.g., 30-200mm), tearing the material into smaller, more manageable chunks.

-

Granulator/Crusher: describes it as a high-speed cutting device. It receives material from the shredder or automatic feeder and precisely cuts it into uniform, specific-sized flakes (e.g., 10-15mm). As mentioned earlier, using "wet granulation" is an advanced practice for improving efficiency and pre-washing.

Sink-Float Tank

This is one of the most critical and core pieces of equipment for achieving material purification. Its working principle is based on Archimedes' principle, using the density of water (or other media) as a benchmark.

-

Function: Separates plastics with a density greater than water from those with a density less than water.

-

Application: This is essential in PET bottle recycling. PET flakes will sink, while PP (Polypropylene) and PE (Polyethylene) materials (from caps and rings) will float. The device can automatically remove the floating and sinking materials separately, achieving a perfect separation of the two plastic types.

Hot Washer System

If the sink-float tank solves "material contamination," then the hot washer system solves "chemical contamination." For enterprises producing high-value, food-grade rPET, this is an indispensable investment.

-

Function: clearly indicates that the hot wash tank uses a combination of high-temperature water (usually heated by steam) and chemical additives (like caustic soda) to dissolve and strip the most stubborn contaminants from PET flakes, especially label glue, oil stains, and residual food/beverages.

-

Importance: emphasizes that using detergents and appropriate warm water to dissolve adhesives is a "vital step to increase product quality." Without this step, residual glue will carbonize during the subsequent melt extrusion process, causing the recycled pellets to turn yellow or have black spots, thereby greatly reducing their economic value.

Squeeze Dryer / Squeezer

This is a key drying equipment designed specifically for PE/PP film and woven bags recycling lines.

-

Challenge: Plastic film, due to its huge surface area and softness, carries a large amount of moisture after washing (humidity can be as high as 30-50%). Traditional centrifugal dryers and hot air dryers are ineffective and extremely energy-intensive.

-

Function: notes that the squeeze dryer uses a special screw design to physically squeeze the material while conveying it forcefully.

-

Result: Moisture is forcibly "wrung" out of the film and discharged through a die head. This is a mechanical dewatering method that can reduce the final film humidity to below 3%-5%. This moisture level is crucial for the subsequent hot-melt pelletizing, as excessive moisture will cause the pelletizing to fail.

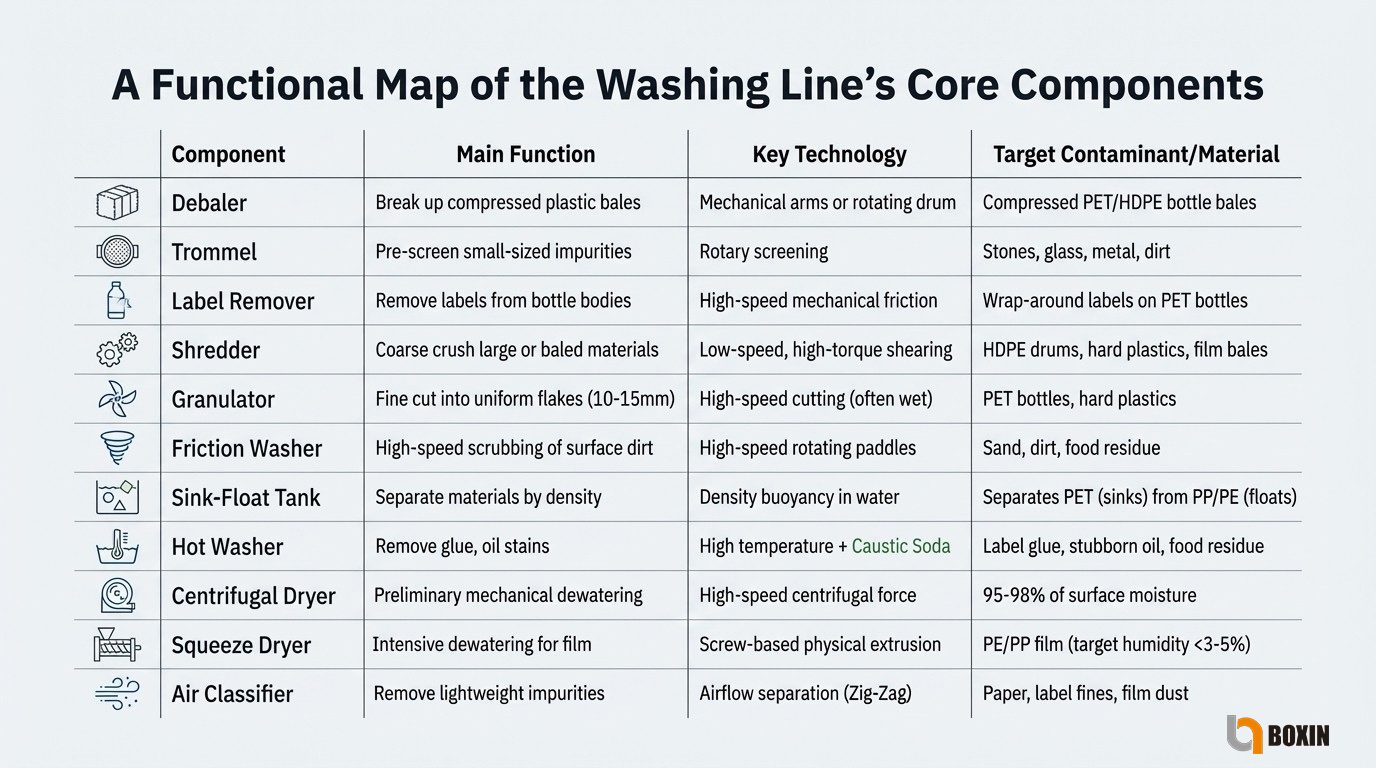

To provide buyers in the evaluation phase with a clear "component function map," the following table summarizes the function, technical principle, and target of each core component of the washing line.

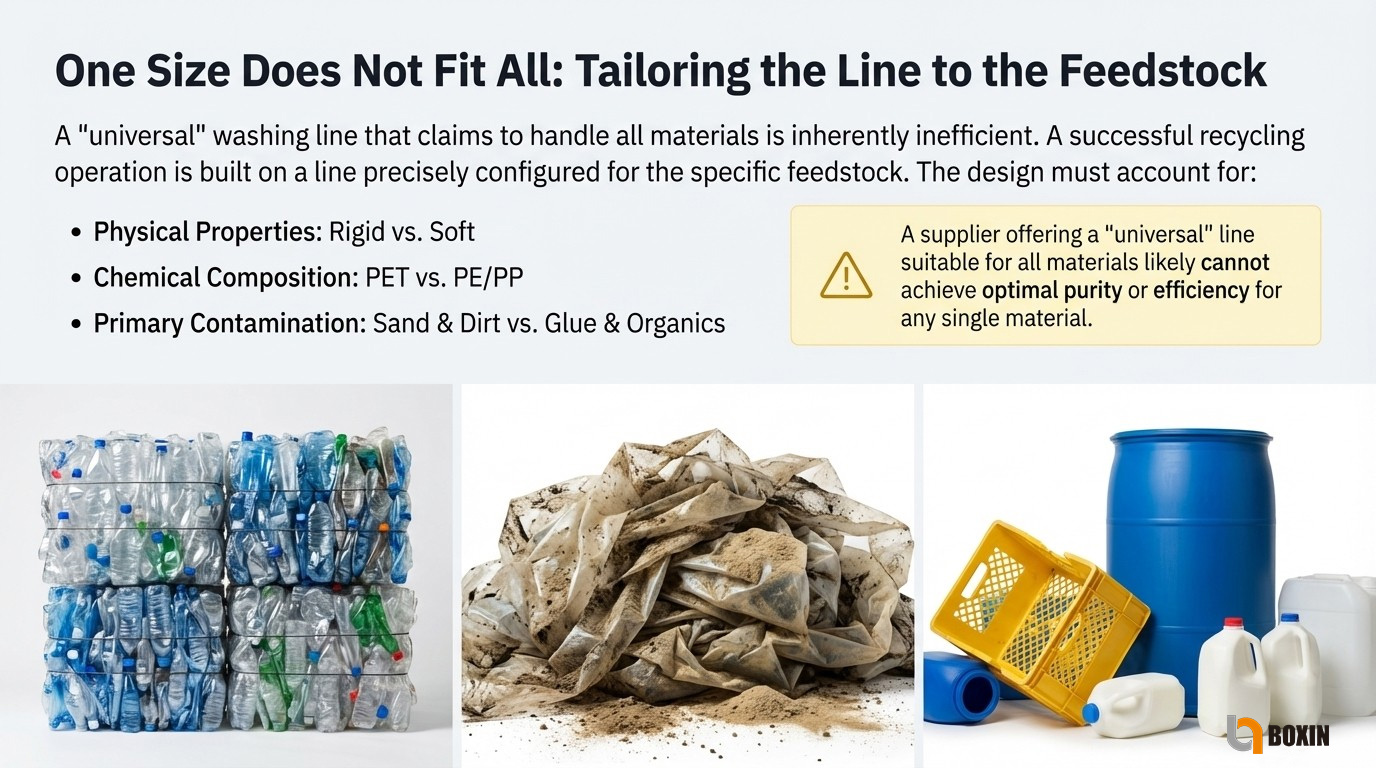

Customization on Demand: Key Differences in Different Waste Plastic Recycling Washing Lines

In the field of plastic recycling, a "one-size-fits-all" washing line does not exist, or is extremely inefficient. A successful recycling business is built on a deep understanding of the specific feedstock. The line's configuration must be precisely customized according to the material's physical properties (rigid vs. soft), chemical composition (PET vs. PE), and primary contamination types (sand vs. glue).

Solution 1: PET Bottle Recycling Washing Line (Application: Bottle-to-Bottle, Fiber)

This is the most mature type of washing line on the market, focusing on processing post-consumer PET beverage bottles, water bottles, etc..

-

Material Characteristics: PET bottle body (Polyethylene Terephthalate).

-

Unique Challenges:

-

Material Mixture: The bottle body is PET, but the caps and rings are usually PP (Polypropylene) or HDPE (High-Density Polyethylene). Labels may be paper, PVC, PS, or other plastics.

-

Contaminants: Beverage and food residues, as well as the strong glue used to affix labels.

-

-

In addition to removing these standard contaminants, different flake grades (to meet downstream extrusion and spinning requirements) are defined by ppm, IV value, color contamination rate (clear flakes, blue-white flakes), etc. Higher grades of flakes require more auxiliary equipment to be added to the basic recycling washing line (the addition or subtraction of auxiliary equipment depends on the bottle source).

Solution 2: PE/PP Film & Woven Bag Washing Line (Application: Re-pelletizing, Blown Film)

This type of production line focuses on processing soft plastics, such as LDPE agricultural film , LLDPE packaging films , and PP woven bags.

-

Material Characteristics: PE (Polyethylene) or PP (Polypropylene), soft texture, large surface area.

-

Unique Challenges:

-

High Contamination: Especially agricultural film, which may contain over 60% sand, stones, and organics.

-

High Humidity: Film is extremely difficult to dry after washing and has very high water retention.

-

-

Key Processes & Equipment:

-

Pre-treatment: emphasizes the necessity of equipping a powerful "pre-crushing and de-sanding system" to efficiently remove large amounts of sand and abrasive impurities, thereby protecting the expensive crusher blades and washing equipment downstream.

-

Intensive Washing: Since contaminants are mainly physical adhesions, these lines rely heavily on high-efficiency "Friction Washers" for intensive scrubbing.

-

Squeeze Dryer: A mandatory option. This is the only effective method to reduce film moisture to acceptable levels (3%-5%). Without it, the subsequent hot-melt pelletizing is almost impossible to perform.

-

Solution 3: HDPE/PP Hard Plastic Washing Line (Application: Re-pelletizing, Injection Molding)

This type of line is used to process other rigid plastic products, such as HDPE milk bottles, shampoo bottles, PE/PP bottle crates, oil drums, trash cans, etc..

-

Material Characteristics: HDPE or PP, material is hard and thick-walled.

-

Unique Challenges: Materials are bulky and structurally robust.

-

Key Process: Requires a heavy-duty shredder for coarse crushing, followed by granulation. The washing process combines friction washing (for decontamination) and sink-float separation (if there are mixed plastics in the raw material).

From the above comparison, it is clear that the design philosophies of different production lines are fundamentally different.

-

The focus of a PET bottle washing line is chemical purification (using hot wash and caustic soda to remove glue) and density separation (using PET's sinking property to separate PP/PE).

-

The focus of a PE/PP film washing line is physical purification (using intensive friction to remove up to 80% of sand) and extreme drying (using PE/PP's floating property , and using a squeeze dryer to reduce humidity to below 3%).

Therefore, potential buyers must first clarify their primary raw material when consulting. If a supplier offers a "universal" line suitable for all materials, it usually means the line cannot achieve optimal efficiency and purity when processing any one specific material, which is a warning sign.

Return on Investment (ROI) & Cost Analysis: How Much Does It Cost to Invest in a Washing Line?

A plastic recycling washing line is a major financial decision. Understanding its cost structure and profit potential is central to a project feasibility study.

Key Factors Affecting the Price of Plastic Recycling Washing Lines

A production line's price is not a single number but is determined by multiple factors.

-

Machine Type and Complexity: A complete PET line that includes advanced sorting, a hot wash system , and wastewater treatment will be priced far higher than a basic PE film line with only crushing and cold washing.

-

Processing Capacity: This is the main price driver. Machines with higher capacity (e.g., 3000 kg/h) have exponential increases in volume, motor power, and manufacturing costs.

-

Automation Level: Fully automated lines require more complex PLC control systems and sensors, thus costing more, but they can save on labor costs.

-

Brand and Manufacturing Location: Long-established European or North American manufacturers often have higher prices due to brand premiums and potentially longer equipment life. Meanwhile, Chinese manufacturers offer competitive prices and mature technology.

Cost Structure: Initial Investment (CapEx) vs. Operating Costs (OpEx)

When evaluating total cost, one must adopt a Life-Cycle Cost Analysis (LCCA) perspective , rather than just looking at the equipment price tag.

-

Initial Investment (CapEx): This includes all one-time expenditures.

-

Equipment purchase cost.

-

Installation and commissioning costs.

-

Factory construction or renovation, and utility (electricity, water, steam) access costs.

-

Operator training costs.

-

-

Operating Costs (OpEx): These are ongoing expenses that directly impact monthly profits.

-

Energy Consumption: Electricity and fuel (e.g., steam) costs for the entire line (especially crushers, hot wash boilers, and dryers).

-

Water Consumption: Costs for fresh water replenishment and wastewater treatment chemicals.

-

Labor Costs: Wages for operation and maintenance personnel.

-

Maintenance and Replacement Costs: Regular replacement fees for wear parts (like blades, screens, bearings).

-

Water-Saving & Wastewater Treatment Systems (Closed-Loop Systems)

Washing lines are major water consumers and simultaneously produce large amounts of wastewater containing organics, detergents, oils, and suspended solids. Therefore, water resource management is central to operational efficiency and environmental compliance.

Modern washing lines are evolving into integrated "water treatment plants." Their goal is to achieve "Closed-Loop Systems" , where water is continuously filtered, purified, and reused within the system.

Key technologies include:

-

Advanced Filtration: Wastewater first passes through physical filtration (like settling tanks, filters) to remove solid impurities (sand, plastic debris).

-

Chemical & Biological Treatment: Using chemical flocculants, pH adjusters, or Dissolved Air Flotation (DAF) to remove dissolved pollutants, grease, and fine particles.

-

Counter-current Flow System: This is an extremely efficient water-saving design. The water flows in the opposite direction of the material movement. This means the dirtiest material (just entering the line) encounters the recycled "dirty" water (for pre-washing), while the cleanest material (about to leave the line) encounters the cleanest makeup fresh water (for final rinsing). This minimizes fresh water consumption while ensuring the highest cleanliness.

EN

EN

English

English 简体中文

简体中文 Русский

Русский España

España عرب .

عرب .