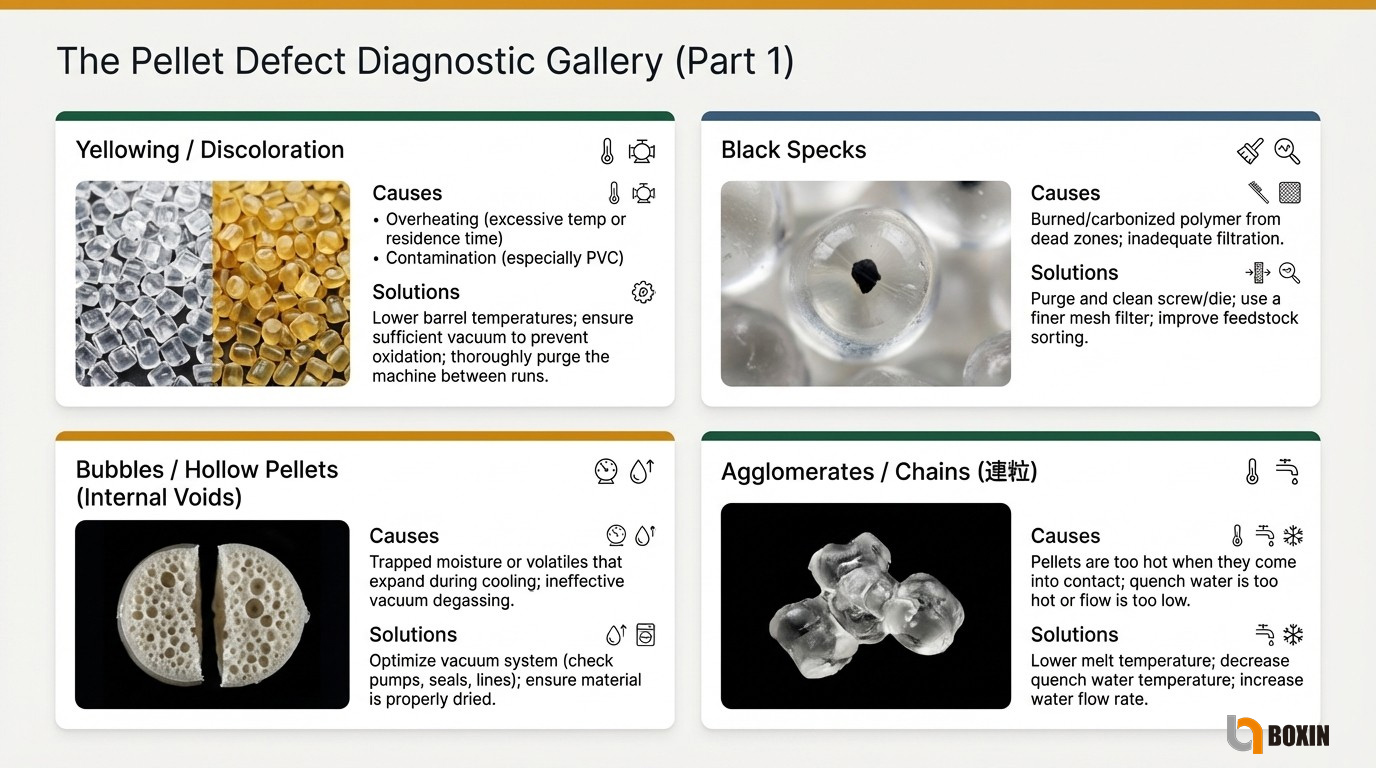

Issue 4: Black Spots or Contaminants in Pellets

Black spots in PET pellets are typically caused by burned polymer or foreign contaminants.

Causes:

-

Polymer degradation (similar to yellowing, but leads to carbonized black fragments).

-

Inadequate filtration, where contaminants aren’t caught by the screen.

Troubleshooting:

-

Purging and cleaning: If black spots appear intermittently, it may be time to stop and clean the extruder screw and die. PET left in dead zones (e.g., behind screens or in sharp corners) can degrade slowly and later break off in chunks. Routine maintenance and cleaning can prevent this buildup.

-

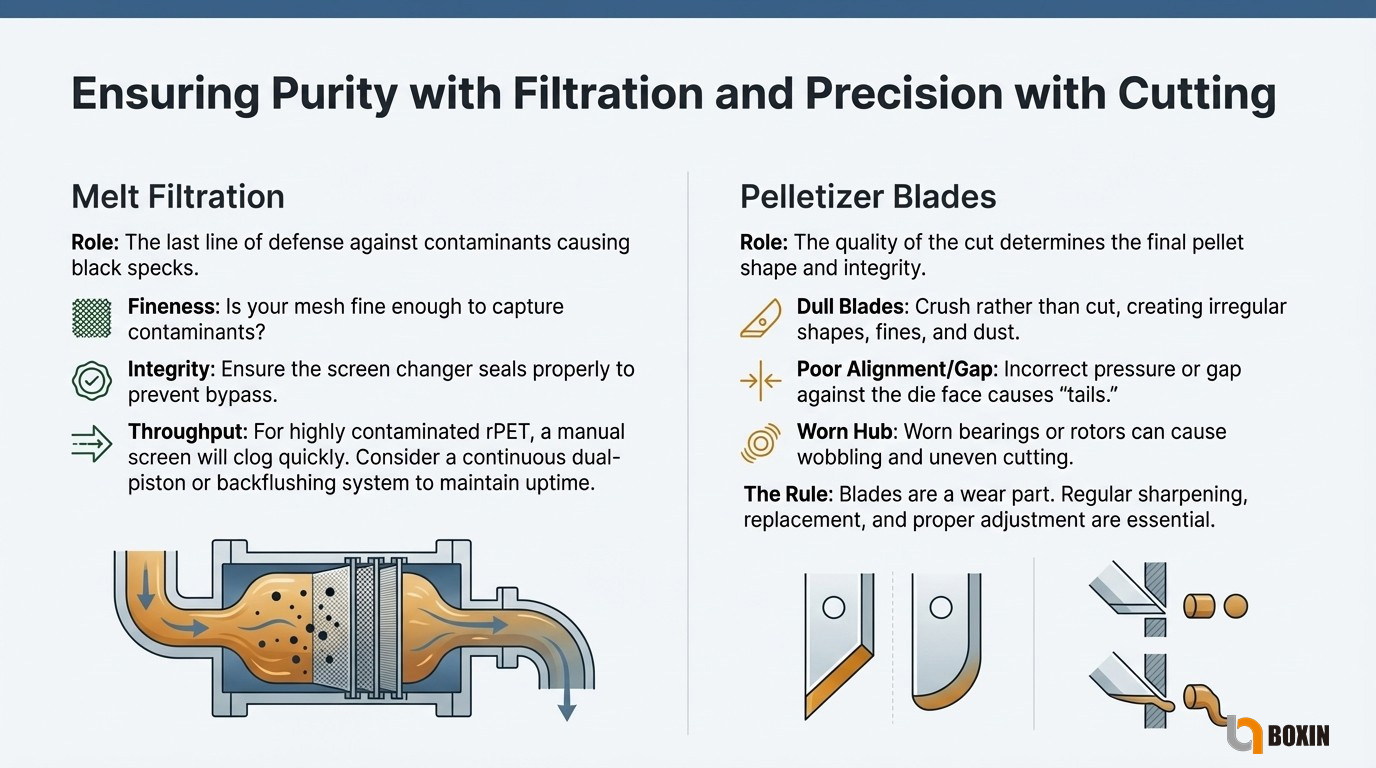

Filtration fineness: Check whether your melt filter is fine enough. If visible specs persist, consider using a finer mesh screen or adding a second filtration stage. Also ensure your screen changer seals properly—any bypass or damaged screen can allow debris through.

-

Feedstock sorting: Upstream, ensure the input flakes are well-sorted—no other plastics, wood, or metal fragments. Even colored paper labels can burn and appear as black specs. If feed contamination leads to persistent black specs, consider installing a melt filter with backflushing capability for continuous contaminant removal.

-

Check pelletizer blades: Though less common, dull blades can generate frictional heat at the cut point and cause localized burning. However, most black spec issues originate in the extruder, not the pelletizer.

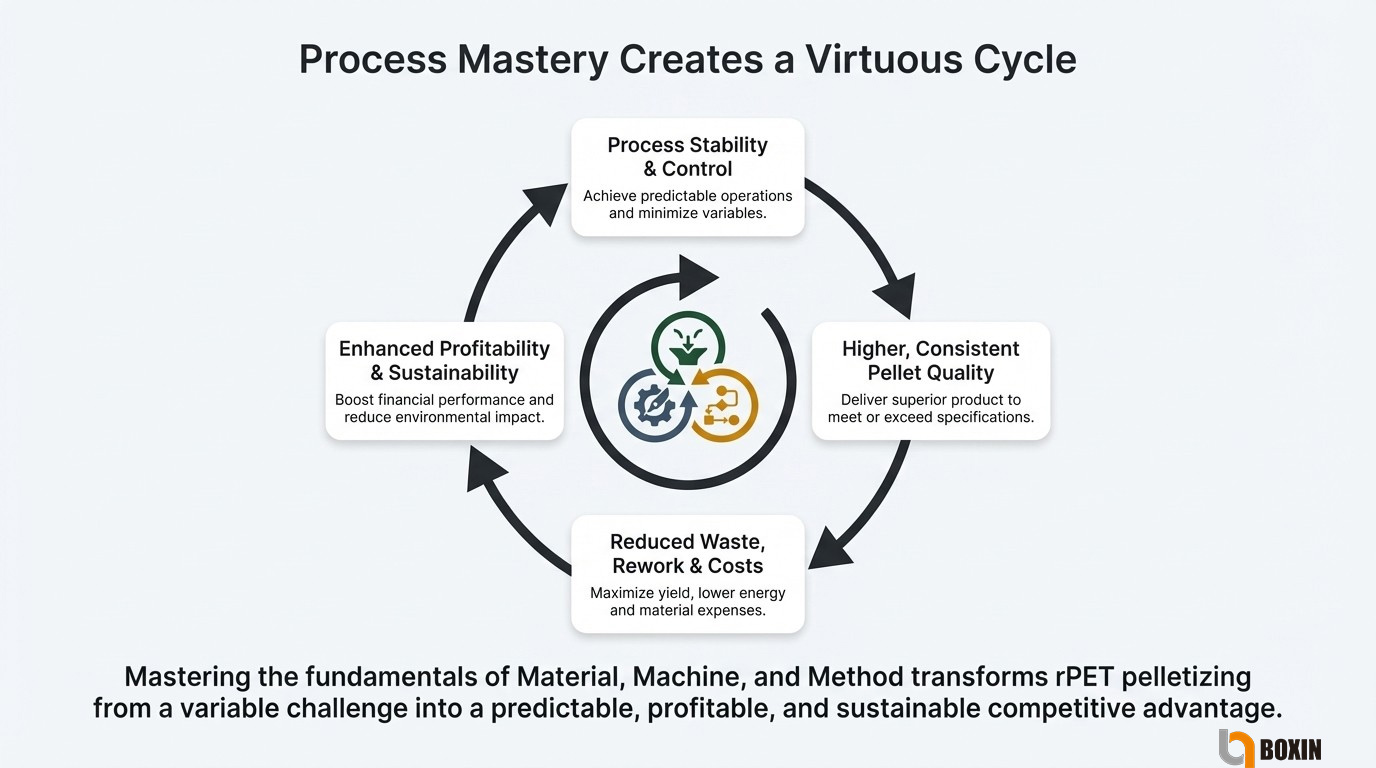

Regular cleaning, effective filtration, and high feedstock purity are crucial to maintaining pellet quality and avoiding black specks that can disrupt downstream applications.

EN

EN

English

English 简体中文

简体中文 Русский

Русский España

España عرب .

عرب .