Mr. Lv is the chief executive officer and is responsible for ensuring that every article we publish is a masterpiece.

What Is a Plastic Recycling Machine?

A Plastic Recycling Machine is specialized equipment designed for the recycling, processing, and reuse of waste plastic materials. Its primary function is to convert plastic waste into reusable plastic flakes or pellets through processes such as crushing, washing, separation, drying, melting, and pelletizing.By turning waste plastics into valuable raw materials, plastic recycling machines help:

| Reduce plastic pollution | Lower raw material costs | Improve overall resource utilization |

Background on plastic pollution:

Globally, about 400 million tonnes of plastics are produced annually, but only 9% are effectively recycled (OECD data).

More than 80% of plastic waste ends up in landfills or in the ocean, leading to serious environmental pollution (UNEP).

Plastic recycling machines are essential tools for reducing plastic pollution and lowering production costs. They have become an important part of the global circular economy.

Modern plastic recycling machines are widely used in plastic recycling plants, manufacturing industries, and downstream plastic product manufacturers. They are capable of processing various types of plastic, such as PET bottles, PE/PP plastic bags, HDPE containers, and ABS electronic plastics.

Depending on the type of plastic and recycling requirements, plastic recycling machines can be divided into different categories, such as Plastic Crusher, Plastic Washing Line, Plastic Shredder, and Plastic Pelletizing Machine. Each type of equipment plays a specific role in the recycling process.

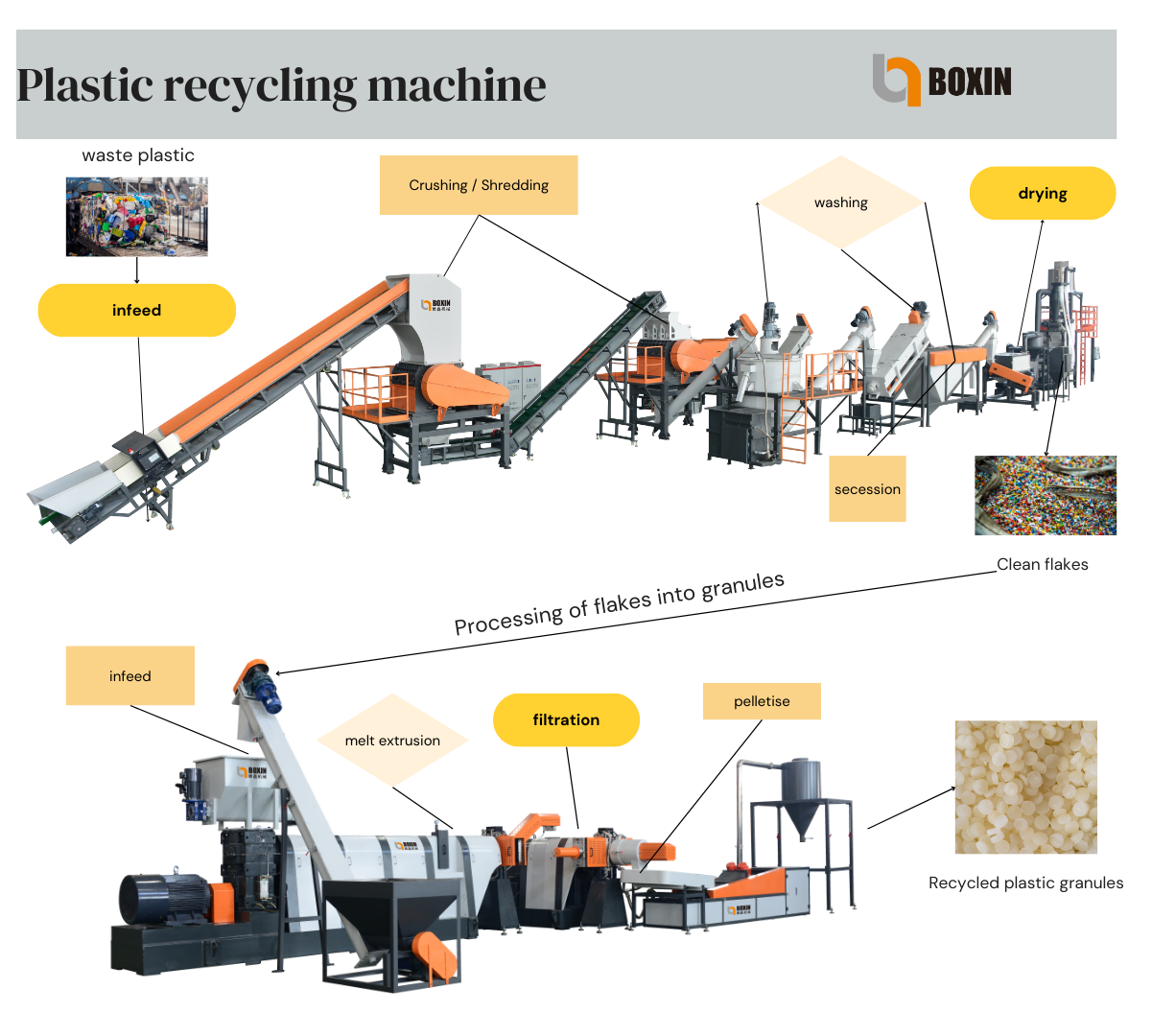

How Does a Plastic Recycling Machine Work?

A plastic recycling machine typically operates in a streamlined, assembly-line fashion, performing a series of physical processes to turn waste plastic into reusable plastic raw materials. The main workflow includes the following steps:

1. Collection & Sorting

The first step is to collect scattered plastic waste or purchase compressed plastic bales. These materials are then roughly sorted by type (e.g., PET, PE, PP) or by removing foreign materials such as metals and glass. This step can be done manually or with basic sorting equipment to improve the efficiency of subsequent processes and the purity of the final product.

2. Size Reduction

The sorted plastic is shredded, crushed, or ground into small flakes or pieces. This reduces the size of bulky waste, making it easier to handle and process in the next steps.

3. Impurity Removal

Washing processes such as friction washing, float separation, or chemical cleaning are used to remove surface contaminants like dirt, oil, and labels. This usually involves multiple cleaning stages—such as high-speed friction washers, float tanks, and hot water washing—to ensure that plastics are separated from impurities with different densities.

4. Drying

The washed plastic is dewatered using a centrifugal dryer or squeezing dryer, followed by hot air drying. Moisture content is reduced to a low level (generally below 1%–3%) to ensure smooth processing during melting and extrusion.

5. Material Separation

Density separation or optical sorting is used to further remove different types of plastics, metals, or foreign particles. This step helps to enhance purity for high-end recycled applications.

6. Melting & Pelletizing

The cleaned and dried plastic is melted, filtered, and extruded into plastic pellets. These pellets are then screened to remove defective materials and packaged as finished recycled products.

Additional steps may be added or removed depending on the material type and process requirements. For example:

-

Mixed plastic waste may require additional manual or optical sorting before shredding.

-

Thin films often go through pre-compacting or agglomeration before extrusion to improve stability.

However, the core recycling process remains: shredding, washing, melting, and pelletizing.

Through these physical processes, bulky and contaminated waste plastics are transformed into clean, processable pellets—significantly improving the efficiency of material reuse.

Main Types of Plastic Recycling Machines

Plastic recycling lines can be categorized based on function, including crushers, washing lines, and pelletizing machines. Each machine handles a different stage in the recycling process and is suitable for processing different forms or types of plastic.

| Machine Type | Main Function | Applicable Plastics |

| Plastic Crusher & Shredder |

Crushers are used to reduce the size of large plastic waste by shredding or cutting it into smaller flakes, making it easier for downstream processing. | Rigid plastics, soft plastics, plastic products |

| Plastic Washing Line | A typical plastic washing line consists of multiple units: separation, pre-washing, friction washing, rinsing, dewatering, and drying. These steps ensure contaminants are removed and materials are prepared for further use. | PET, PP, PE, HDPE |

| Plastic Pelletizing Machine | Pelletizing machines (often part of a complete pelletizing line) are centered around an extruder that melts shredded plastic through heating. The molten plastic is extruded into continuous strands, which are then cooled and cut into uniform pellets by a pelletizer (either strand-cut or underwater system). | Soft plastics, PE film, PET bottles |

How to Choose the Right Plastic Recycling Machine?

Choosing the right plastic recycling machine involves multiple factors, including the type of plastic material, processing capacity, equipment configuration, energy consumption, maintenance cost, and budget. Below is a detailed selection guide:

1. Identify the Type of Plastic to Be Recycled

Different plastics have different melting points and physical characteristics, which determine the suitable recycling method. For example:

-

Transparent plastics like PET require high-purity sorting

-

Soft plastics like PE film require special extrusion systems

-

PP plastic granulation often requires a two-stage pelletizing system

2. Select the Appropriate Type of Equipment

Depending on the cleanliness of raw materials and desired end product, plastic recycling equipment can be divided into the following categories:

(1) Crusher / Shredder

-

Input Material: Relatively clean plastic waste

-

Function: Reduces the size of plastic into smaller flakes

-

Recommended For: In-house recycling, small-scale operations

(2) Plastic Washing Line

-

Input Material: Contaminated or dirty plastic waste

-

Function: Processes waste plastics into clean flakes or regrind

-

Recommended For: Waste plastic recycling plants

(3) Pelletizing Machine

-

Input Material: Clean flakes or recycled material

-

Function: Converts clean plastic into uniform plastic pellets

-

Recommended For: Plastic pellet manufacturers

3. Determine Your Required Processing Capacity

The capacity of the machine affects your ROI (Return on Investment). Choose based on your production needs:

-

Small-scale recycling stations: 500 kg/h

-

Medium-sized recycling plants: 1000–3000 kg/h

-

Large industrial factories: 3000 kg/h and above

EN

EN

English

English 简体中文

简体中文 Русский

Русский España

España عرب .

عرب .