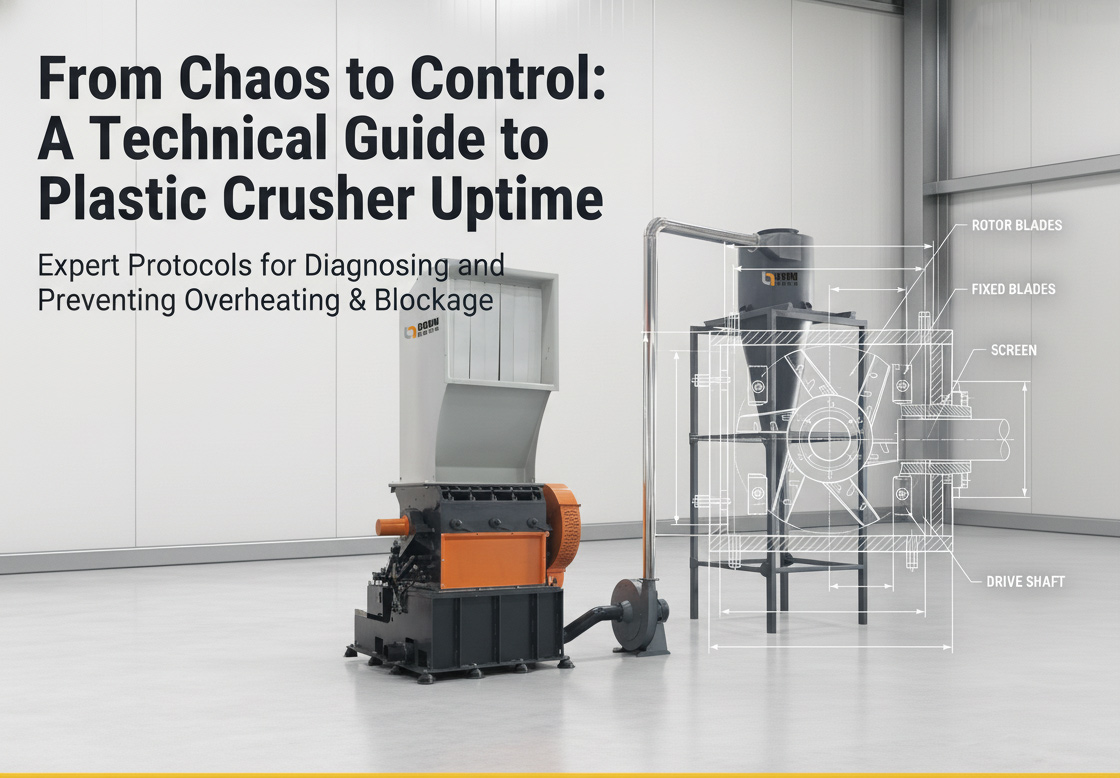

This guide provides a professional and operational framework for diagnosing, resolving, and preventing the two most common operational failures in plastic granulation: overheating and material jamming. These issues are primary drivers of unscheduled downtime, directly impacting recycling throughput and overall profitability.

Root Cause Analysis: Crusher Overheating

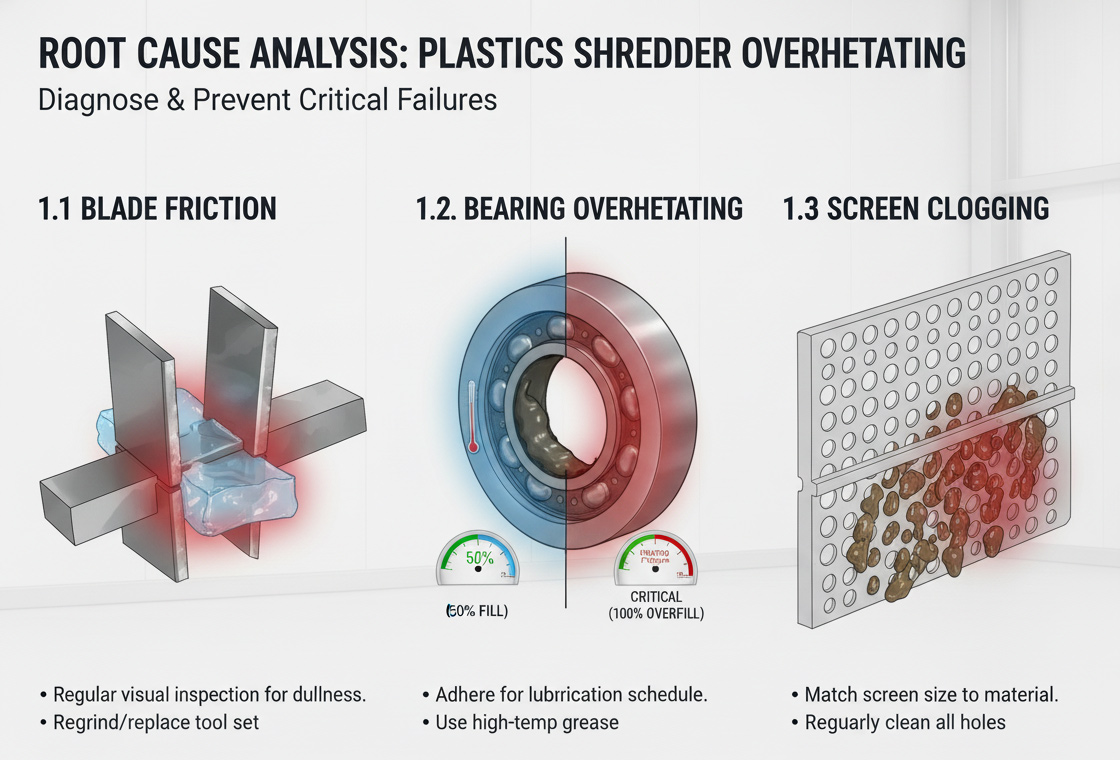

Overheating is a critical failure mode in plastic crushers, typically originating from excessive friction within the cutting chamber or the main bearings. Uncontrolled heat leads to the thermal degradation of the processed plastic, which contaminates the equipment and compromises end-product quality. In severe cases, overheating can result in significant mechanical damage, including bearing seizure and catastrophic motor failure.

Friction from Dull Blades or Improper Clearance

Dull blades fundamentally alter the cutting process. Instead of a clean shearing action, the blades begin to tear, smash, and compress the plastic. This inefficient motion generates immense friction, creating substantial heat within the cutting chamber.

Corrective Actions:

-

Establish a schedule for regular visual inspections of all blade edges.

-

Regrind or replace tool sets immediately upon signs of rounding or wear.

-

Optimization: Maintain correct blade clearance to ensure precise scissor-like cutting. For most applications, this clearance should be calibrated between 0.2mm – 0.5mm.

Improper Bearing Lubrication and Cooling

Bearing temperature is a direct indicator of machine health. Overheating in this area presents two distinct risks: insufficient lubrication leads to direct metal-to-metal friction and rapid heat buildup; conversely, over-lubrication increases fluid resistance within the housing, generating heat while obstructing effective dissipation.

Corrective Actions:

-

Strictly adhere to the documented lubrication schedule specified by the equipment manufacturer.

-

Use high-quality, high-temperature lithium-based grease designed for heavy-duty applications.

-

Optimization: To allow for thermal expansion and efficient heat dissipation, bearing housings should only be filled to 50% volume. Overfilling causes churning and resultant heat.

Screen Clogging (Blinding)

The screen determines the final particle size and controls the discharge of material from the cutting chamber. When the screen becomes clogged (the "blinding" phenomenon), sized particles cannot exit. Trapped material is forced to circulate with the rotor, intensifying friction and heat until the plastic begins to melt and adhere directly to the screen structure, exacerbating the blockage.

Corrective Actions:

-

Ensure the screen mesh size is matched to the specific material being processed and the required throughput.

-

Periodically clean the screen to remove accumulated molten plastic and ensure all apertures are clear.

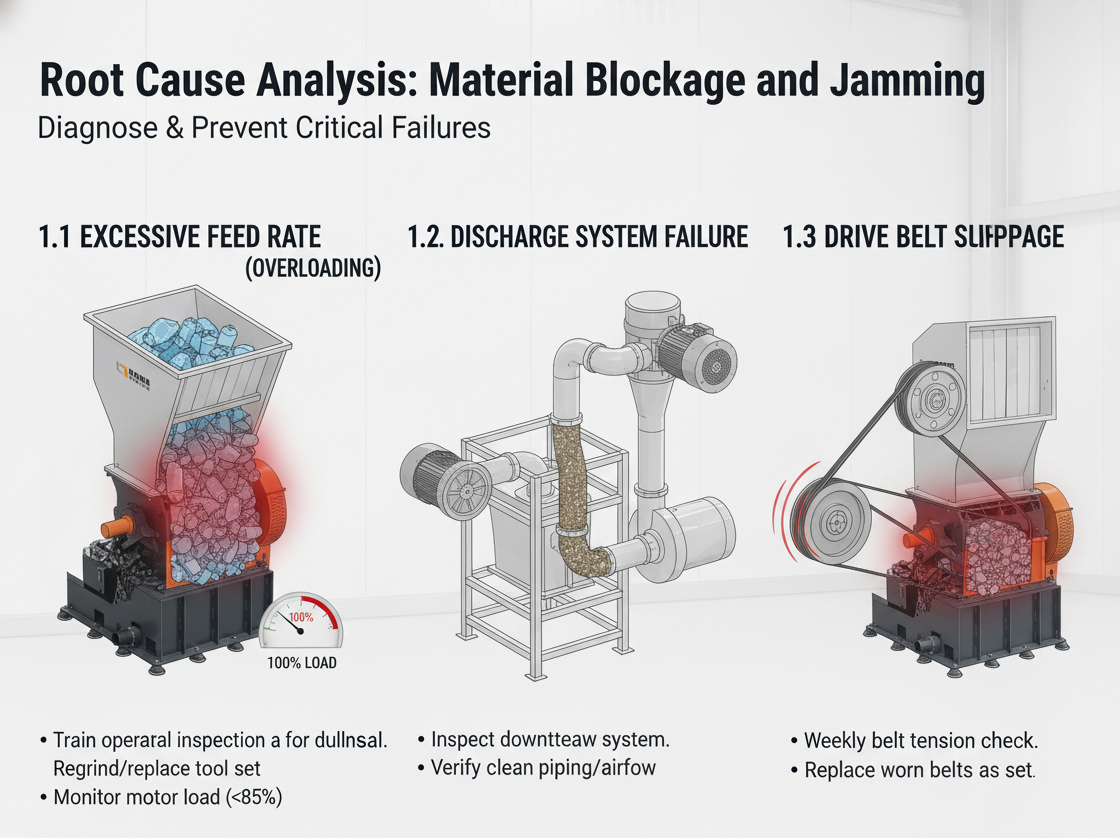

Root Cause Analysis: Material Blockage and Jamming

Material blockage or jamming is usually caused by operational errors or mechanical bottlenecks, leading to an abrupt rotor stall. Such events result in immediate and costly downtime and pose significant safety risks to personnel clearing the jam.

Excessive Feed Rate (Overloading)

Every crusher has a maximum processing capacity. If the feed rate exceeds the rotor’s cutting and discharge speed, the cutting chamber will inevitably become paralyzed. This overload condition places extreme stress on the motor and drive system, leading to a stall.

Corrective Actions:

-

Train operators to feed material at a uniform, consistent rate that matches the machine's capacity.

-

Prohibit the direct dumping of large batches of unsorted material into the hopper.

-

Optimization: Install an ammeter on the main control panel to display motor load in real-time. The core operating rule should be to maintain current below 85% of the rated load. If current spikes, the operator must stop feeding immediately until the load stabilizes.

Discharge System Failure

A plastic crusher does not operate in isolation; it is part of an integrated material handling system. Any failure or bottleneck in the discharge path—such as a clogged suction blower, a jammed screw conveyor, or a kinked pipe—causes processed material to back up into the cutting chamber, triggering a jam.

Corrective Actions:

-

Regularly inspect the entire downstream conveying system from the crusher outlet to the collection point.

-

Verify that discharge piping is free of obstructions or sharp bends and confirm the blower generates sufficient air pressure for effective material evacuation.

Drive Belt Slippage

V-belts are responsible for transmitting torque from the motor to the crusher rotor. If belts are loose or worn, they will slip on the pulleys under high loads (e.g., when blades hit extra-thick plastic). This slippage causes an instantaneous loss of cutting torque, which is often sufficient to stall the rotor and cause a jam.

Corrective Actions:

-

Inspect the tension of all drive belts weekly.

-

If belts are found to be loose, worn, or cracked, they must be re-tensioned or replaced as a complete set. Replacing only a single belt leads to uneven tension and unstable torque transmission.

Material-Specific Troubleshooting Protocols

Different polymers possess unique physical and thermal properties, requiring distinct processing strategies.

Soft Plastics (LDPE / PP Film)

Soft, flexible materials like LDPE and PP films are extremely difficult to crush. Their low melting points make them prone to melting from frictional heat, and their flexibility often causes the material to wrap around the rotor and blades rather than being cut.

-

Countermeasures: Blades must be kept extremely sharp with a tighter clearance (approaching 0.2mm). Increasing rotor speed can also facilitate decisive shearing before the material elongates or melts.

Rigid, Brittle Plastics (PET / ABS / Nylon)

Rigid, brittle plastics like PET, ABS, and Nylon require significant energy to crush. This process generates substantial frictional heat and subjects blade edges to high impact stress, increasing the risk of chipping.

-

Countermeasures: A slightly wider blade clearance (approaching 0.5mm) is recommended to promote clean fracture. Adopting a lower rotor speed may be beneficial to reduce the rate of heat generation. For high-throughput applications, investing in high-impact tool steel or blades with specialized shear angles can significantly improve performance and longevity.

Troubleshooting Matrix: Rapid Diagnosis and Action

| Symptom | Potential Root Cause | Immediate Corrective Action |

| High Amperage (>85%) or Rotor Stall | Excessive feeding; Clogged discharge; Dull blades | Stop feeding immediately. Verify discharge path is clear. Schedule blade inspection. |

| Severe Bearing Heat (>70°C) | Improper lubrication (excessive or insufficient) | Shutdown. Cool. Inspect and adjust grease according to lubrication schedule. |

| Decreased Throughput / Molten Plastic in Output | Screen blockage/blinding; Excessive friction from dull blades | Shutdown. Inspect and clear screen apertures. Schedule blade sharpening. |

| Rotor Stall on Hard Material; Squealing Sound | Drive belt slippage due to wear or looseness | Shutdown. Perform LOTO. Check belt tension and wear. |

| Material Bouncing Back into Hopper | Discharge system failure; Clogged screen | Shutdown. Perform LOTO. Clear discharge conveyor, piping, and screen. |

Comprehensive Preventive Maintenance Schedule

Daily Inspections (Pre-shift)

-

Visual Check: Inspect for loose bolts, fasteners, or safety guards.

-

Monitor Ammeter: Ensure motor load remains consistently below 85% of rated capacity during operation.

-

Listen for Abnormal Noise: Listen for new vibrations or sounds that may indicate loose blades or bearing failure.

-

Check Discharge Flow: Confirm processed material exits smoothly with no signs of backup.

-

Bearing Temperature Check: Use a non-contact infrared thermometer to verify bearing housings are below the 70°C critical threshold.

Weekly Inspections

-

Belt Tension and Condition: Inspect all V-belts for wear, cracks, or hardening. Adjust tension as required.

-

Bearing Lubrication: Apply specified lithium-based grease according to the lubrication schedule and the 50% fill principle.

Monthly Inspections

-

Blade Clearance Calibration: Remove access panels and use feeler gauges to verify the gap between rotating and stationary blades is within the 0.2mm – 0.5mm specification.

-

Screen Wear and Damage: Remove and thoroughly clean the screen; check for excessive wear, cracks, or permanent blinding.

Critical Safety Protocol: Lockout/Tagout (LOTO)

WARNING: ALWAYS ADHERE TO LOTO PROCEDURES Before attempting to clear a jam, inspect or grind blades, adjust belts, or perform any form of maintenance, the machine must be completely de-energized. Lockout/Tagout (LOTO) is a non-negotiable safety requirement. This involves isolating the crusher from its power source (e.g., at the main circuit breaker) and applying physical locks and warning tags. This procedure ensures the equipment cannot be started accidentally while personnel are working on it, preventing severe personal injury.

Conclusion: Shifting from Reactive Repair to Proactive Control

Operational excellence in plastic recycling stems from shifting the mindset from reactive "firefighting" to a proactive approach based on preventive maintenance and standardized operation. By strictly enforcing the protocols in this guide, your team can ensure the mechanical integrity of the crusher, directly extending equipment life, stabilizing throughput, and guaranteeing production safety. This proactive control is the key to maximizing the profitability of a recycling business.

FAQ & Expert Tips: Most Common Buyer Questions

Straight Answers to the Questions You Might Be Hesitant to Ask

EN

EN

English

English 简体中文

简体中文 Русский

Русский España

España عرب .

عرب .