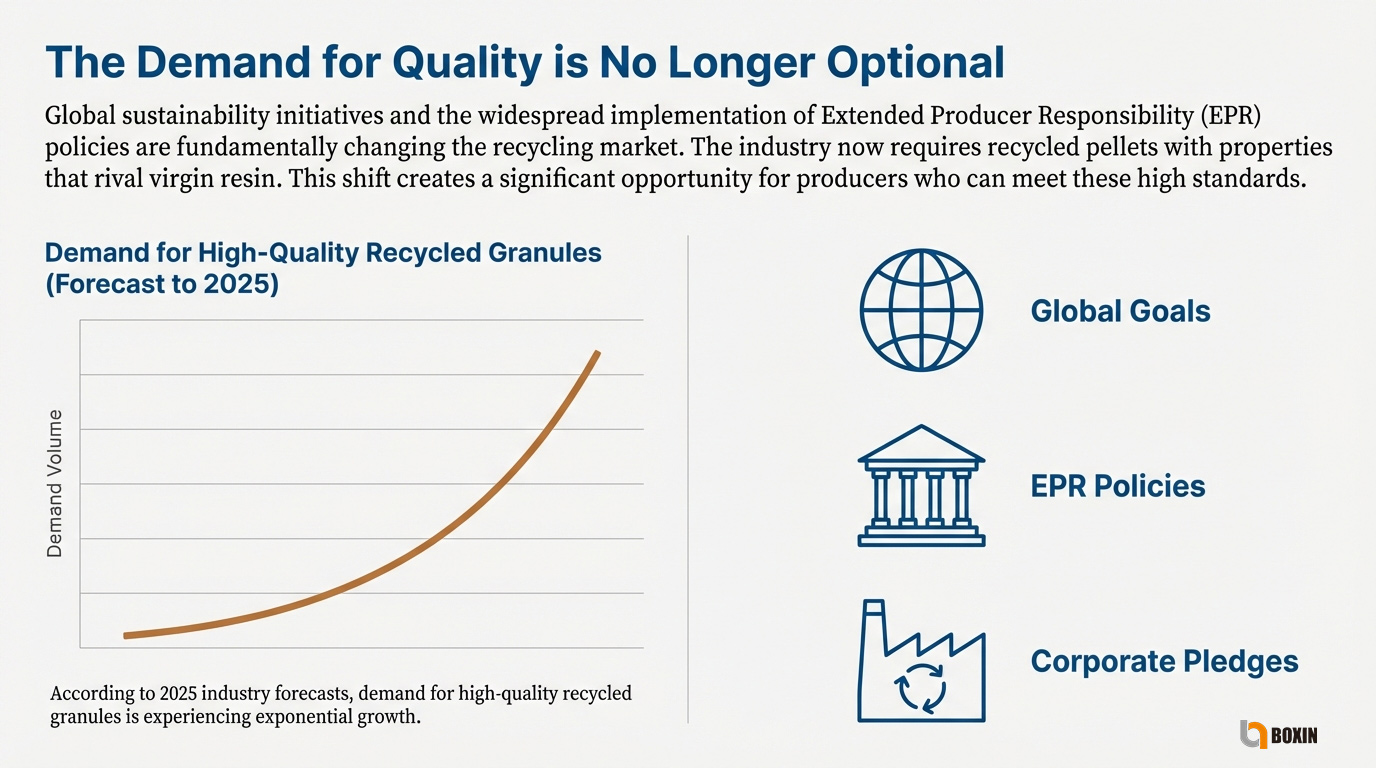

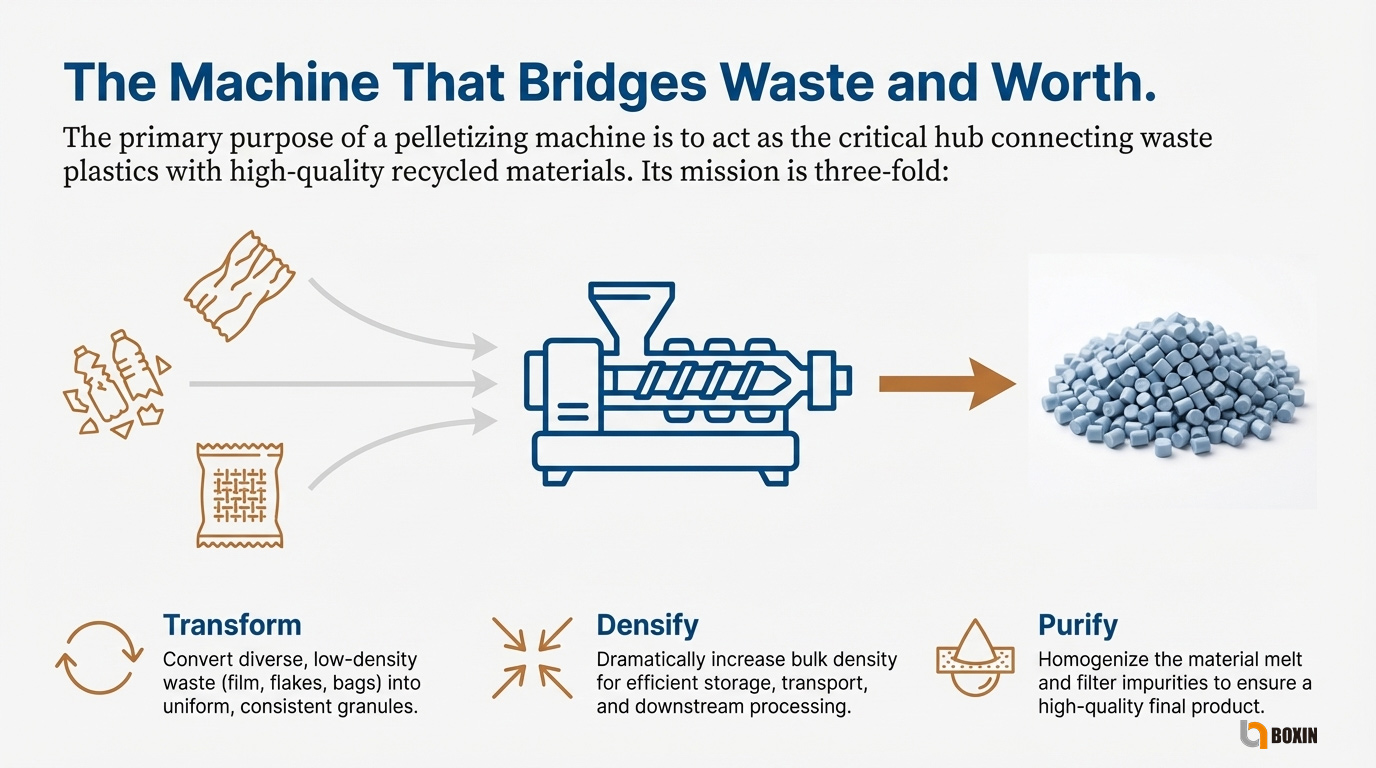

Against the global backdrop of pursuing sustainability and a circular economy, the Plastic Pelletizing Machine (or Plastic Extrusion Granulator) has evolved beyond mere industrial equipment; it is now the critical hub connecting waste plastics with high-quality recycled materials. According to 2025 industry forecasts, the implementation of Extended Producer Responsibility (EPR) policies worldwide is driving exponential growth in demand for high-quality recycled pellets/granules.

The core mission of a pelletizing machine is to convert diverse, bulky waste plastics (such as films, woven bags, regrinds, and bottle flakes) into granules with uniform physical properties, high bulk density, and ease of transport or re-processing. This is a complex engineering system involving thermodynamics, rheology, and mechanical engineering.

For recycling plants, understanding the operational principles is vital. Efficient systems must handle not only commodity plastics like PP (Polypropylene) and PE (Polyethylene) but also engineering plastics like PET (Polyethylene Terephthalate) and PA (Nylon), which are highly sensitive to moisture and temperature. Modern machines ensure that the Intrinsic Viscosity (IV) and mechanical properties of recycled pellets closely match virgin resin by precisely controlling melt pressure, temperature, and residence time.

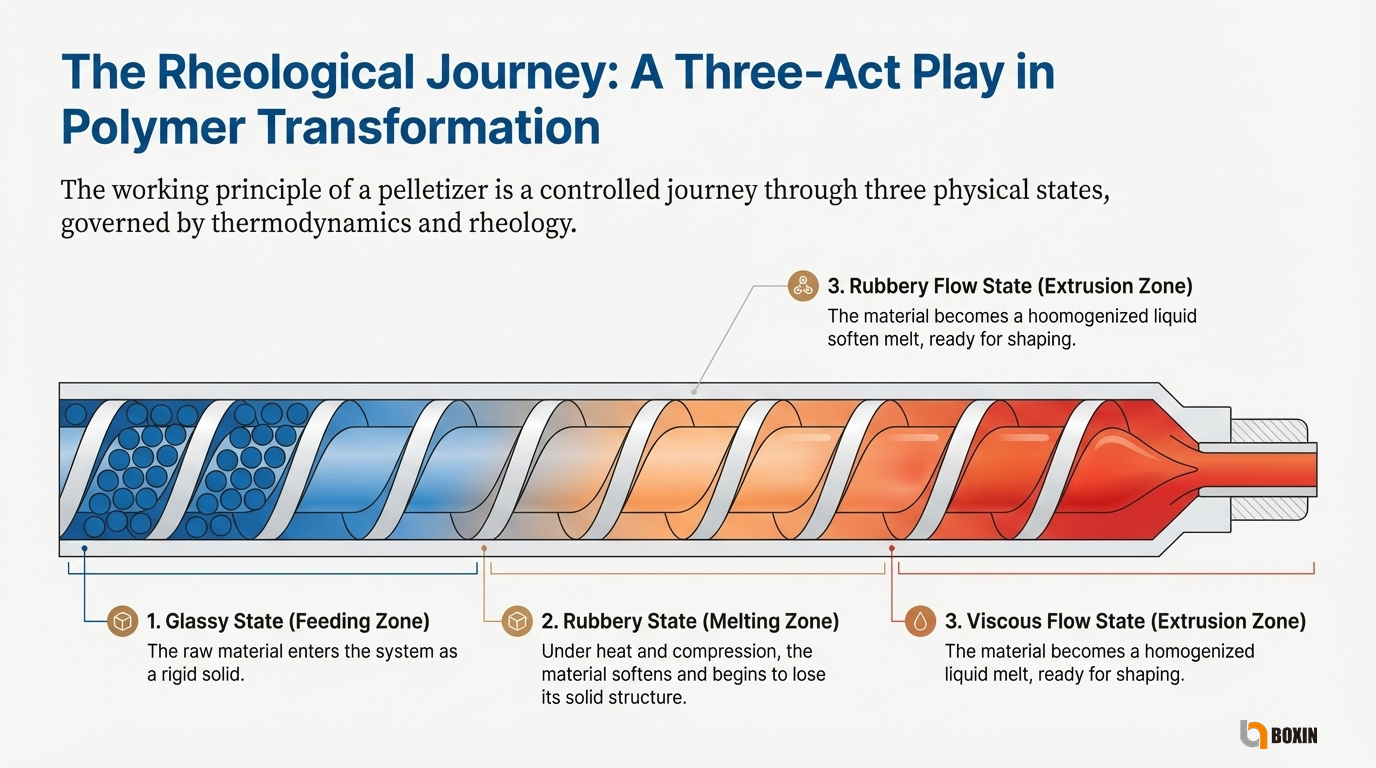

Working Principle: The Rheological Process from Solid to Melt

The working principle is based on polymer extrusion theory. While external heating provides the initial energy, core energy during stable production stems from the conversion of mechanical energy into thermal energy. The process involves three physical state transitions: Glassy State, Rubbery State, and Viscous Flow State.

Raw Material Feeding & Solid Conveying

The process begins with raw materials entering the feeding port in a glassy, solid state.

- Gravity vs. Force Feeding: Rigid regrinds with good flowability use gravity feeding. However, low-bulk-density films or filaments require a force feeder or cutter compactor. The compactor uses frictional heat from high-speed blades to pre-heat and semi-plasticize material, using centrifugal force to feed the screw, which prevents "bridging."

- Engagement & Conveying: Screw rotation creates friction between the barrel wall and the material. According to solid conveying theory, the material must adhere to the barrel while "slipping" on the screw to move forward. Therefore, grooved feed bushings are often used to increase the friction coefficient.

Melting & Plasticization: The Role of Shear Heat

As material is pushed toward the head (compression section), the screw channel shallows, subjecting the material to intense compression.

-

External Heating: Electric or induction heaters provide initial heat to melt the plastic layer against the barrel wall.

-

Shear Heating: In high-speed extrusion (300–600 rpm), internal friction between molecular chains and metal surfaces generates 60%–80% of the required thermal energy for polyolefins (PP/PE), rather than the external heaters.

-

Homogenization: In the metering section, mixing elements (e.g., Maddock or pin elements) ensure uniform temperature and highly even distribution of additives or masterbatches.

Extrusion & Pellet Formation

The homogenized melt is pushed at high pressure (15–30 MPa) through a screen changer to filter impurities and finally through the die head.

- Pressure Stability: Fluctuations lead to inconsistent pellet size. High-precision melt pumps are often installed before the die head to ensure stable, continuous output.

Technical Composition & Key Systems Analysis

The Extrusion System: Screw & Barrel

-

Screw Geometry:

-

L/D Ratio: 20:1–24:1 for heat-sensitive materials (PVC); 28:1–32:1 for PP/PE film recycling; 36:1+ for deep degassing or reactive extrusion.

-

Compression Ratio: PP/PE usually require 3:1–4:1; PET requires a low ratio to prevent shear-induced IV degradation.

-

-

Material Science: For abrasive recycled materials containing sand or metal, bimetallic barrels/screws with tungsten carbide alloys offer 3–5 times the wear resistance of nitrided steel, maintaining ideal clearances (0.3–0.5 mm).

-

Venting System: Vacuum degassing is essential for printed or washed waste to remove moisture, ink solvents, and volatiles. Double or triple venting is becoming standard for high-moisture (>5%) processing.

The Transmission System

-

Motor: Servo motors or high-efficiency AC motors with VFDs (Variable Frequency Drives) can save 10%–15% energy compared to older DC motors.

-

Gearbox: Must feature a high torque factor and hardened gears to withstand the frequent load shocks typical of unstable recycling feedstocks.

Heating & Cooling System

-

Heating: Cast aluminum (high thermal inertia), Ceramic (fast heating), or Infrared (30% higher efficiency).

-

Cooling: Air or water cooling systems intervene when shear heat exceeds setpoints to prevent scorching or degradation.

Pelletizing System Comparison

| Feature | Strand Pelletizing | Water Ring / Die Face | Underwater Pelletizing |

| Principle | Extruded strands -> Water bath -> Cutter | Die-face cut -> Centrifugal water ring | Die-face cut submerged in water |

| Shape | Cylindrical | Lenticular | Spherical |

| Materials | Engineering plastics (PET, PA), rigid PP/PE | Polyolefins (PE, PP), filled compounds | High-viscosity (TPU), high-output, micro-pellets |

| Automation | Low (manual re-stranding) | Medium/High | Very High (One-button start) |

| Maintenance | Low cost | Medium | High (Precision die, complex water system) |

| Typical Output | 200 - 2,000 kg/h | 200 - 2,000 kg/h | 1,000 - 10,000+ kg/h |

| Insight | Best for PET | Film recycling "Value King" | Premium recycled resin/High premium |

Material-Specific Processing Optimization

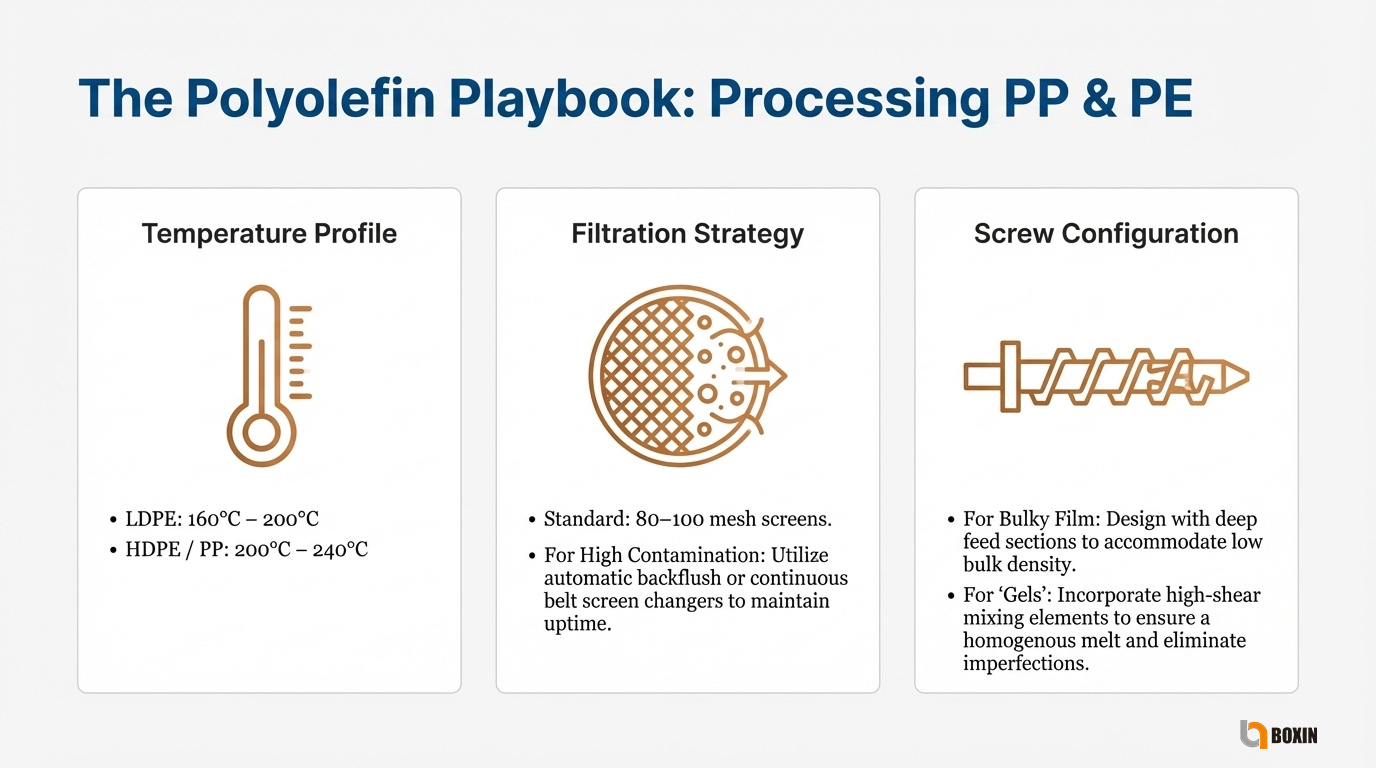

PP & PE

-

Temperature: LDPE (160°C–200°C); HDPE/PP (200°C–240°C).

-

Filtration: 80–100 mesh screens. For high contamination, use automatic backflush or scraper systems.

-

Screw Strategy: Deep feed sections for bulky film; high shear for "gels."

PET

-

Pre-treatment: Requires drying (160°C for 4–6 hours, <50ppm moisture) or high-vacuum twin-screw degassing.

-

IV Protection: Use low-shear configurations and control temperatures (260°C–280°C) to prevent yellowing or brittleness.

-

Crystallization: Recommended post-pelletizing to facilitate storage and downstream processing.

Troubleshooting & Maintenance Guide

| Issue | Root Cause | Solution |

| Hollow Pellets | High melt temp; trapped volatiles; cold water | Lower temp; clear vacuum vent; increase water temp |

| Agglomeration | High water temp; dull blades; low RPM | Increase water flow; sharpen blades; increase RPM |

| Black Spots | Carbonization (dead zones); dirty raw material | Purge screw; check temp controllers; improve washing |

| Strand Breakage | Pressure fluctuation; clogged screen; impurities | Change screen; stabilize feeding; use metal separator |

| Melt Fracture | High shear (Sharkskin); cold die | Reduce RPM; increase die temp; use PPA additives |

Preventative Maintenance

-

Daily: Test E-stops, clear hopper magnets, check for oil leaks.

-

Weekly: Lubricate bearings, tighten heater bolts (prevent efficiency loss due to thermal expansion).

-

Monthly/Quarterly: First gearbox oil change at 300–500 hours, then every 3,000–4,000 hours. Measure screw wear; replace if clearance exceeds 0.5 mm. Clean electrical cabinet filters.

EN

EN

English

English 简体中文

简体中文 Русский

Русский España

España عرب .

عرب .